In the world of manufacturing, the concept of tolerances in precision cutting is fundamental. Achieving the correct tolerances ensures that parts fit together perfectly, function flawlessly, and meet the high standards required by modern industries. Understanding the importance of tolerances in precision cutting is crucial, especially for precision metal cutting techniques, which play a pivotal role in shaping the future of manufacturing.

What are Tolerances?

Tolerances are the permissible limits of variation in a physical dimension that are allowed between two or more parts. In precision cutting, tolerances determine how accurately and consistently a part can be produced to its specified dimensions.

The Impact of Tolerances on Manufacturing

Tolerances play a significant role in the overall quality of a manufactured product. They ensure that different parts can be assembled without issues, hence maintaining the structural integrity and functionality of the final product.

Types of Tolerances

There are several types of tolerances in precision cutting, each catering to different aspects of the manufacturing process:

- Dimensional Tolerances: Controls the allowable variations in part dimensions.

- Geometric Tolerances: Refers to allowable variations in part shape and geometry.

- Surface Tolerances: Defines the permissible surface roughness and quality.

Importance of Precision in Cutting

Maintaining precision in cutting is crucial for ensuring that parts meet the required tolerances. High precision in cutting processes results in enhanced quality, reduced material waste, and improved production efficiency.

Factors Affecting Precision Cutting

Several factors influence precision cutting, including:

- Material Properties: The hardness and thermal conductivity of the material can affect cutting precision.

- Cutting Method: Different methods, such as precision cutting methods, offer varying levels of precision.

- Tool Condition: Well-maintained tools ensure consistent and precise cuts.

Technological Advancements in Precision Cutting

With the advent of technology, precision cutting has seen unprecedented advancements. CNC machines, laser cutters, and waterjet metal cutting technology are just a few examples that have revolutionized the industry.

How CNC Machines Enhance Precision

CNC machines provide automated control over precision cutting processes, ensuring that parts are cut with exceptional accuracy and repeatability.

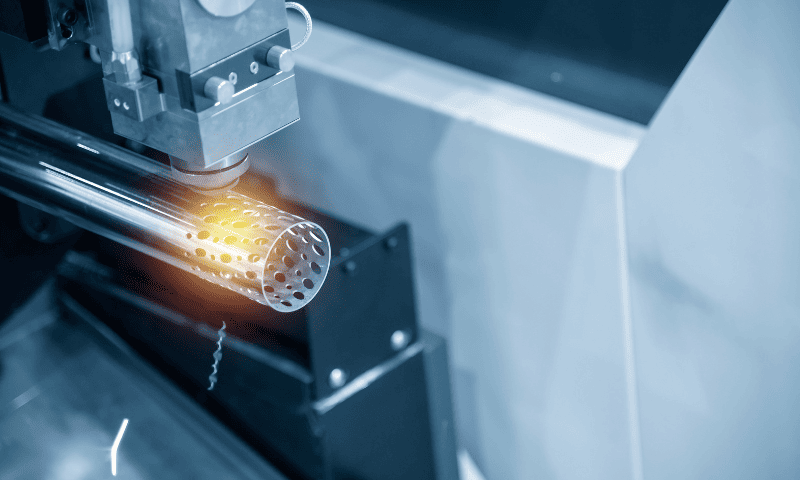

The Role of Laser Cutting in Precision

Laser cutting offers unparalleled precision, making it ideal for intricate designs and complex geometries. Laser cutting maintains high-quality edges, reducing the need for additional finishing processes.

Ensuring Quality Through Tolerances

Maintaining strict tolerances ensures that parts produced are of high quality. Quality control in precision cutting involves checking and rechecking dimensions to ensure compliance with the specified tolerances.

Inspecting Tolerances

Regularly inspecting tolerances during the manufacturing process prevents defects and ensures that the final products meet customer expectations.

Challenges in Maintaining Tolerances

While maintaining tolerances is essential, manufacturers often face challenges in doing so consistently. Factors such as material inconsistencies, tool wear, and human error can lead to deviations.

Overcoming Tolerance Challenges

Regular calibration of tools, employing automation, and comprehensive training for operators can help overcome challenges in maintaining strict tolerances.

The Cost of Deviations

Deviations from specified tolerances can result in rejected parts, increased waste, and a negative impact on profitability. Thus, adhering to tolerances is vital for operational success.

Conclusion

Understanding and maintaining tolerances in precision cutting is a cornerstone of modern manufacturing. By implementing advanced technologies and rigorous quality control measures, manufacturers can ensure high-quality production that meets the demands of an ever-evolving market.

FAQ Section

What are the common types of precision cutting methods?

Common types of precision cutting methods include EDM cutting, laser cutting, and waterjet cutting.

Why are tolerances important in manufacturing?

Tolerances ensure that parts fit together correctly, function as intended, and meet safety and performance standards.

How does technology aid in maintaining precision?

Technology such as CNC machines and laser cutters ensures high precision and repeatability, reducing human error and enhancing production efficiency.

This article contains affiliate links. We may earn a commission at no extra cost to you.