-

Steel, an indispensable material in construction, automotive, and infrastructure, is constantly evolving through the integration of advanced materials and innovative manufacturing techniques. In an era focused on sustainability, efficiency, and enhanced performance, the steel industry is undergoing a transformation to meet emerging market demands. This article explores the groundbreaking materials and techniques reshaping the future…

-

The steel manufacturing industry is undergoing a radical transformation with the rise of smart factories powered by the Internet of Things (IoT). IoT connects machines, processes, and people through sensors and digital platforms, enabling real-time data exchange and automation. In the steel industry, where efficiency, precision, and cost management are paramount, IoT plays a critical…

-

Steel stamping, a critical process in industries like automotive, aerospace, and construction, is experiencing a transformative shift. With advancements in artificial intelligence (AI) and automation, manufacturers can now achieve unprecedented levels of efficiency, precision, and scalability. This article delves into how AI and automation are revolutionizing steel stamping and shaping the future of manufacturing. The…

-

✴︎ Blog

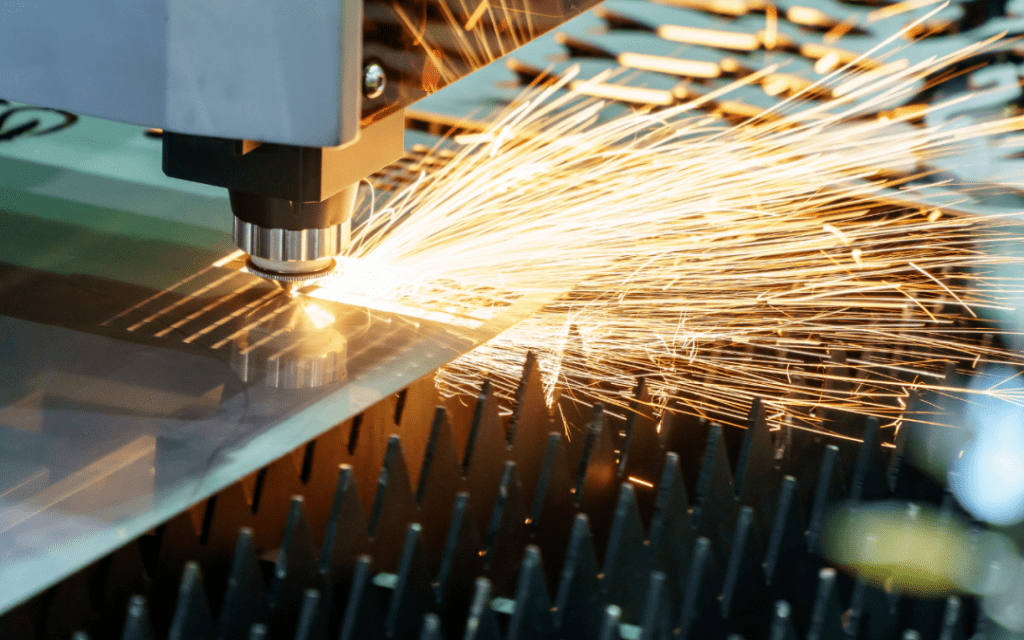

Cutting Stainless vs. Mild Steel: Key Differences and Techniques

When it comes to cutting stainless vs. mild steel, understanding the unique properties of each material is crucial for achieving optimal results. Both stainless steel and mild steel are widely used in industrial manufacturing, but they require different approaches due to their distinct characteristics. Buy AI-Driven Quality Control System Understanding the Basics Before delving into… Read More

OUR RECENT POSTS

Technology & Innovation

Quality Control

Effective quality control is critical to ensuring that steel stamping operations produce parts that meet industry standards, function correctly, and maintain safety and reliability. In this article, we will cover the best practices in quality control, methods to detect defects in steel stamping, and how innovative solutions like the StroboX system have transformed…

Techniques

Steel stamping is a crucial process in manufacturing that allows for the mass production of parts with high precision and consistency. Different stamping techniques cater to varying complexity, strength, and tolerance requirements. Below are the key techniques used in steel stamping, ranging from basic methods to advanced techniques that meet…

Industry Insights

-

Precision Metal Cutting for Effective Prototyping

In the realm of manufacturing, precision metal cutting for prototyping plays a crucial role in developing accurate models. This process ensures that each piece is cut with the utmost accuracy, paving the way for successful production. With advancements in technology, manufacturers have leveraged modern metal cutting techniques to achieve new levels of precision. The relevance…

-

Thin Metal Cutting Techniques: Precision and Modern Methods

In the realm of industrial manufacturing, the art and science of thin metal cutting techniques hold significant importance. As manufacturing demands increase, understanding and applying these techniques become crucial for efficiency and precision. Within the first two paragraphs of this article, we will delve into what makes these techniques indispensable for today’s industrial landscape. Buy…

-

Importance of Accuracy in Metal Cutting for Manufacturers

The importance of accuracy in metal cutting cannot be overstated, especially in today’s highly precision-driven industries. With advancements in technology and an increasing demand for flawless products, precision has become a vital component in the manufacturing process. Industries worldwide are increasingly recognizing how critical precise metal cutting is to their operations. Accurate metal cutting not…

-

Precision Cutting in Automotive Industry: Navigating Trends

In the fast-paced world of the automotive industry, precision cutting has emerged as a pivotal process that ensures the production of high-quality components. As vehicles evolve to meet increasing consumer demands, the role of precision cutting becomes even more significant. Understanding its importance can offer insights into modern manufacturing techniques that drive the industry forward.…

-

Metal Cutting for Medical Devices: Choosing the Right Solutions

In the world of medical device manufacturing, precision is paramount. As technology advances, the demand for intricate and precise metal components continues to rise. Here, we’ll explore the critical role of metal cutting for medical devices and its significance in the industry. Buy AI-Driven Quality Control System Understanding the Importance of Precision The realm of…

-

Sustainability and Efficiency: The Future of Steel Production

The steel industry is a cornerstone of global manufacturing, providing essential materials for construction, automotive, aerospace, and numerous other sectors. However, the environmental impact of steel production, characterized by high energy consumption and carbon emissions, has prompted a significant shift towards sustainability and efficiency. This article explores the trends, technologies, and practices shaping the future…

Resources & Publications

-

In the world of manufacturing, low-volume precision cutting is a crucial process that ensures the creation of high-quality components with exact specifications. This technique is especially significant for industrial manufacturers, where precision and accuracy are paramount. By employing low-volume precision cutting, manufacturers can meet the demands of specialized projects while maintaining efficiency and cost-effectiveness. Buy…

-

In the world of industrial manufacturing, the ability to cut metal in high volumes efficiently and accurately is crucial. Whether you’re working with thick sheets of steel or delicate aluminum, understanding the intricacies of high volume metal cutting can lead to better productivity and cost-effectiveness. This article will delve into the methods, tools, and strategies…

-

In the realm of industrial manufacturing, choosing a precision cutting partner is a crucial decision that can significantly impact the efficiency and quality of your production process. Whether you’re involved in low-volume precision cutting or cutting at high volumes, selecting the right partner ensures that your projects are completed with accuracy and on time. Understanding…