Stamping die troubleshooting is a critical aspect of the manufacturing process that ensures the efficiency and quality of metal parts. For industrial manufacturers, understanding the nuances of this process is vital for maintaining productivity and minimizing downtime. This article delves into the key challenges and solutions associated with stamping die troubleshooting, providing valuable insights for both seasoned professionals and newcomers in the industry.

Understanding Stamping Dies

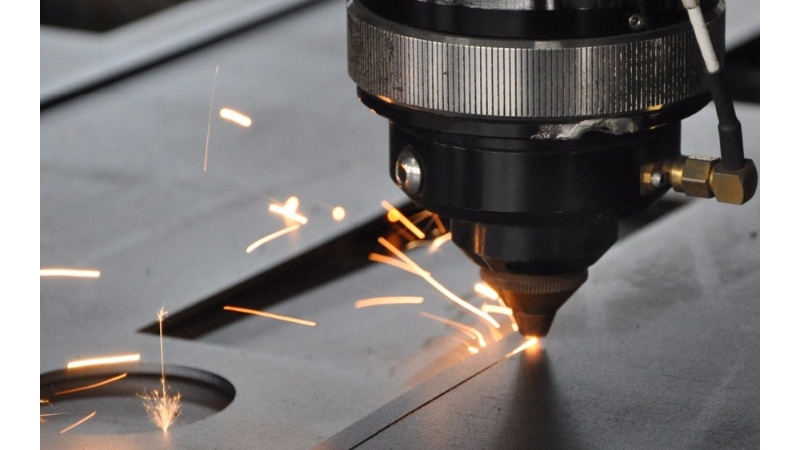

In the world of metal fabrication, stamping dies are essential tools used to cut and shape metal sheets into desired forms. These dies are integral to various industries, including automotive, aerospace, and electronics. However, they are not without their challenges. Regular wear and tear, improper maintenance, and material inconsistencies can lead to production issues.

Common Issues in Stamping Die Operations

Material Fracture

One of the most frequent problems encountered in stamping operations is material fracture. This occurs when the metal being stamped cracks or breaks instead of forming as intended. Factors contributing to material fracture include incorrect material hardness, improper die clearance, and excessive force application.

Die Misalignment

Die misalignment is another common issue that can significantly affect the quality of stamped parts. This occurs when the die components are not properly aligned, leading to uneven pressure distribution and defective products. Ensuring precise alignment is crucial for optimal performance.

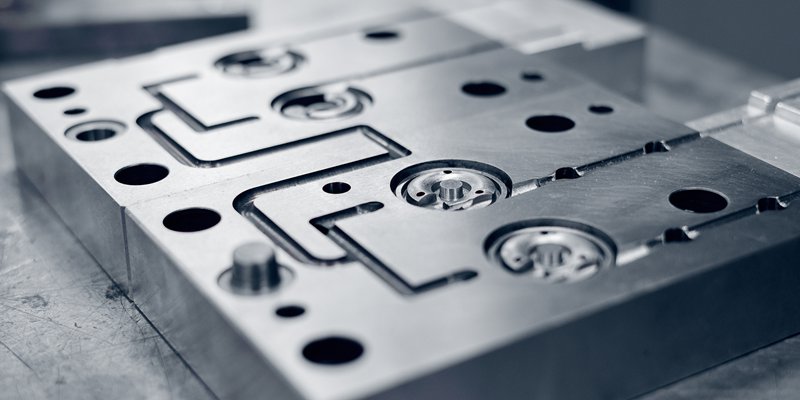

Wear and Tear on Dies

Over time, dies undergo wear and tear, which can compromise their performance. Regular inspections and maintenance are essential to identify signs of wear, such as burrs, cracks, or deformation. Implementing a proactive maintenance schedule can extend the lifespan of dies and reduce operational disruptions.

Effective Stamping Die Troubleshooting Techniques

Regular Maintenance and Inspection

Conducting regular maintenance and inspection is paramount in preventing unexpected failures. This includes checking for wear, cleaning components, and lubricating moving parts. By maintaining a routine schedule, manufacturers can identify potential issues before they escalate.

For further insights on maintaining quality in stamping production, visit Quality Control.

Material Selection and Testing

Choosing the right material for stamping operations is crucial. Manufacturers should conduct thorough material testing to ensure compatibility with the die and process requirements. This helps in reducing instances of material fracture and enhances overall product quality.

Aligning and Calibrating Dies

Proper alignment and calibration of dies are essential to avoid misalignment issues. Utilizing precision tools and equipment, such as those discussed in our precision equipment section, can aid in achieving accurate alignment and optimal performance.

Advanced Troubleshooting Techniques

Utilizing Technology for Monitoring

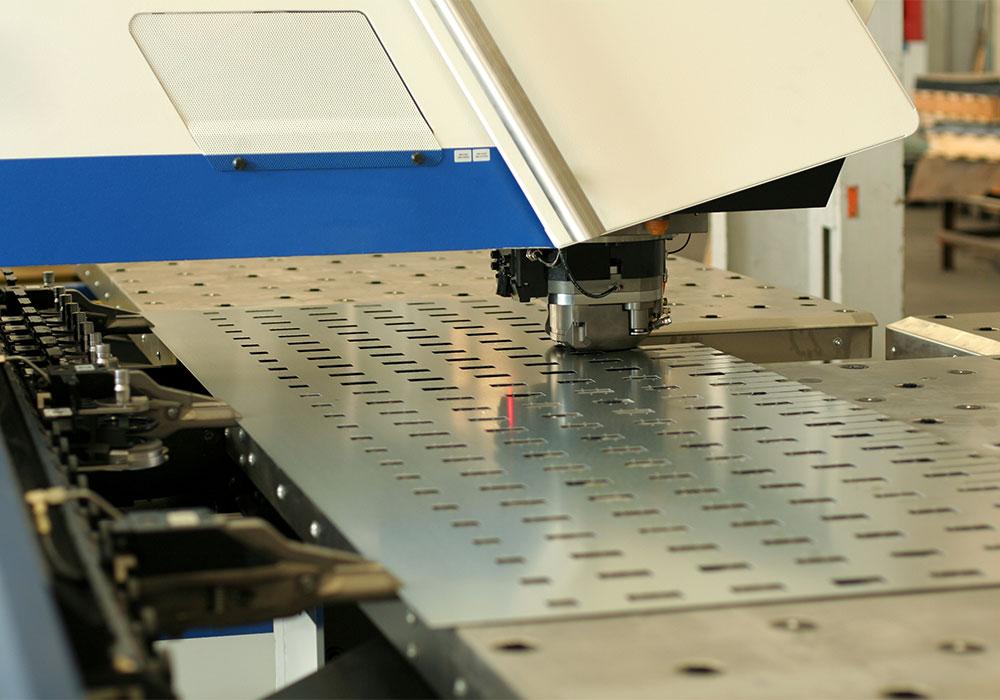

Incorporating advanced technology, such as sensors and monitoring systems, can provide real-time data on die performance. This proactive approach enables manufacturers to detect anomalies early and take corrective measures promptly.

Training and Skill Development

Investing in employee training and skill development is essential for effective troubleshooting. Skilled operators are better equipped to identify and address issues quickly, minimizing downtime and ensuring consistent production quality.

FAQs on Stamping Die Troubleshooting

What are the signs of die wear?

Signs of die wear include burrs, cracks, and deformation on the die surface. Regular inspections can help identify these issues early.

How can material fracture be prevented?

Preventing material fracture involves selecting the right material, ensuring proper die clearance, and applying the correct force during stamping.

Why is die alignment important?

Die alignment ensures even pressure distribution and prevents defects in stamped parts. Proper alignment is crucial for maintaining product quality.

For more information on the mechanics of stamping, check out this press machine guide.

For additional information on metal stamping, visit our inspection techniques page.

By understanding and implementing these troubleshooting techniques, industrial manufacturers can enhance the efficiency and quality of their stamping operations. Embracing technology, prioritizing maintenance, and fostering skill development are key strategies for overcoming challenges and achieving success in the competitive world of metal fabrication.

This article contains affiliate links. We may earn a commission at no extra cost to you.