When it comes to investing in stamping equipment, one of the first decisions you must make is whether to purchase used or new stamping equipment. This decision can significantly impact your manufacturing operations, financial health, and overall productivity. Both options have their pros and cons, and understanding these can guide you to make the best choice for your production needs.

In this article, we will explore the key differences between used vs new stamping equipment, and help you decide which option is most suitable for your business. This choice is crucial in the world of industrial manufacturing, where efficiency and cost-effectiveness are paramount.

Understanding Stamping Equipment

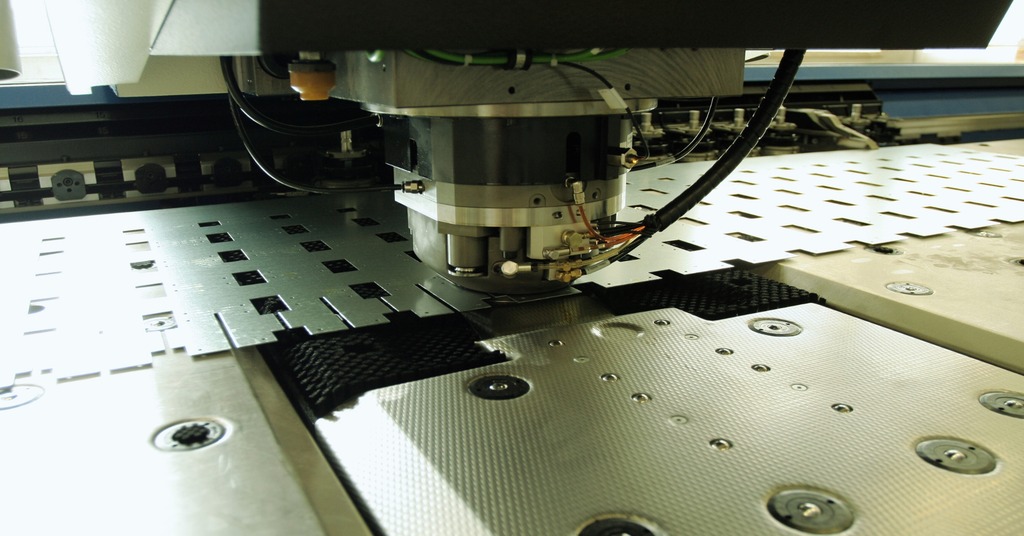

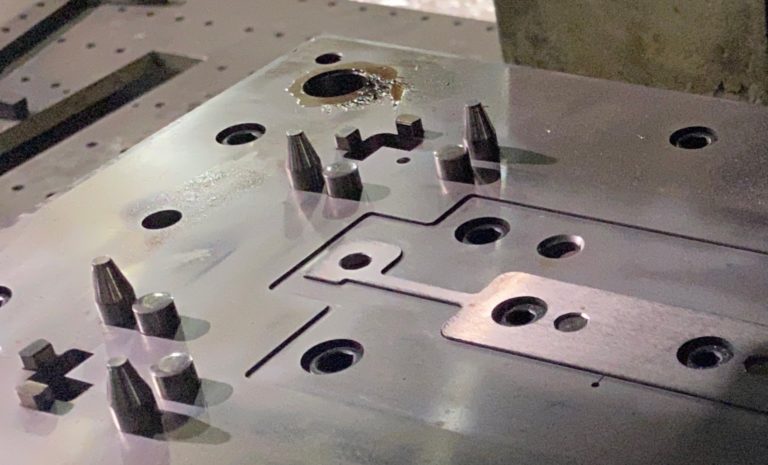

Before diving into the comparison of used vs new stamping equipment, it is essential to understand what stamping equipment entails. Stamping equipment is used in the manufacturing process to shape or cut metal into specific forms. This is achieved through a process involving dies and a press, which can be mechanical or hydraulic.

Types of Stamping Equipment

There are several types of stamping equipment available, each designed for specific tasks:

- Mechanical Presses: These are known for their speed and are typically used for high-volume production.

- Hydraulic Presses: These offer more control and are ideal for complex, precision tasks.

- Servo Presses: These combine the benefits of both mechanical and hydraulic presses, offering speed and precision.

Advantages of New Stamping Equipment

Investing in new stamping equipment offers several benefits:

Advanced Technology

New equipment often comes with the latest technology, which can enhance productivity and precision. With advancements in automation and computer controls, new machinery can deliver higher efficiency and better quality products.

Reliability and Warranty

New equipment usually comes with a warranty, providing peace of mind and protection against potential failures. This reliability can be crucial for maintaining continuous production without unexpected downtimes.

Customization

New machines can be customized to meet the specific needs of your production line, offering flexibility that used machines may not provide.

Disadvantages of New Stamping Equipment

Despite the advantages, there are also some drawbacks to consider:

High Initial Cost

The most significant disadvantage of new equipment is the high initial investment required. This can be a barrier for small or medium-sized businesses with limited budgets.

Depreciation

New machinery tends to depreciate quickly, which can impact the financial statements of a business.

Advantages of Used Stamping Equipment

On the other hand, used stamping equipment has its own set of benefits:

Cost-Effectiveness

Used machinery is significantly cheaper than new equipment, allowing businesses to allocate funds to other critical areas.

Immediate Availability

Used equipment is often available immediately, which means you can start production without waiting for new machinery to be manufactured and delivered.

Proven Performance

Used machines have a track record, and any potential issues are usually already known, allowing for informed purchasing decisions.

Disadvantages of Used Stamping Equipment

However, there are also some potential downsides:

Potential for Wear and Tear

Used equipment may have significant wear and tear, which can lead to more frequent repairs and maintenance.

Lack of Modern Features

Older machines may lack the advanced features and technology found in newer models, which could limit efficiency and output quality.

Compatibility Issues

Used equipment may not be compatible with modern production processes or software systems, which could require additional investment to update or adapt.

Factors to Consider When Choosing Stamping Equipment

When deciding between used vs new stamping equipment, consider the following factors:

Budget

Your budget is a critical factor in determining whether to invest in new or used equipment. Assess your financial resources and consider the long-term cost implications of each option.

Production Needs

Evaluate your production requirements, including volume, precision, and complexity. This will help you determine the type of equipment that will best meet your needs.

Future Growth

Consider your business’s growth potential and whether the equipment you choose will be able to accommodate increased production demands in the future.

Maintenance Capabilities

Assess your ability to maintain the equipment. New machines may require less maintenance, while used machines could need more frequent servicing.

Conclusion

Choosing between used vs new stamping equipment is a significant decision that can impact your manufacturing operations. Each option has its advantages and disadvantages, and the right choice will depend on your specific needs, budget, and long-term goals.

For more information on metal stamping processes, you can check out Metal Stamping Inspection Techniques and Stamping Machine Operator Training on Modern Metalworks.

Additionally, you can learn more about the workings of a stamping press by visiting this external source.

FAQ

What is the main difference between used and new stamping equipment?

The primary difference lies in cost, technology, and reliability. New equipment is more expensive but comes with the latest technology and warranties, while used equipment is more cost-effective but may require more maintenance.

Is it better to buy used equipment if I have a limited budget?

Yes, if you have budget constraints, buying used equipment can be a viable option. However, ensure that you assess the condition of the equipment to avoid frequent repairs.

Can used stamping equipment be integrated into modern production lines?

Integration is possible, but it may require additional investment in upgrades or adaptations to ensure compatibility with modern systems.

This article contains affiliate links. We may earn a commission at no extra cost to you.