In the realm of manufacturing, precision metal cutting for prototyping plays a crucial role in developing accurate models. This process ensures that each piece is cut with the utmost accuracy, paving the way for successful production. With advancements in technology, manufacturers have leveraged modern metal cutting techniques to achieve new levels of precision.

The relevance of precision metal cutting is undeniable, especially in industries where exactitude is key. This article delves deep into understanding its importance, methods, and future potential.

Understanding Precision Metal Cutting

Precision metal cutting is the art and science of creating exact cuts in metal, essential for prototyping and end products. This process provides the necessary detail to bring design concepts to life, ensuring product reliability and functionality.

The choice of techniques varies and depends on the projects requirements. From laser techniques to waterjet cutting, each method offers unique advantages.

Types of Metal Cutting Techniques

Several methods exist for precision metal cutting:

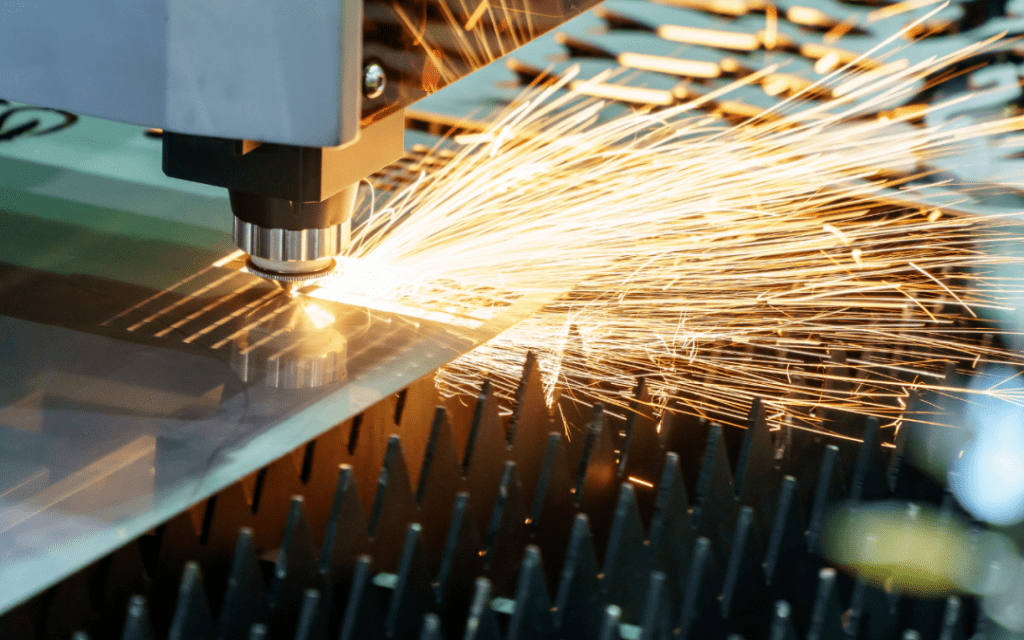

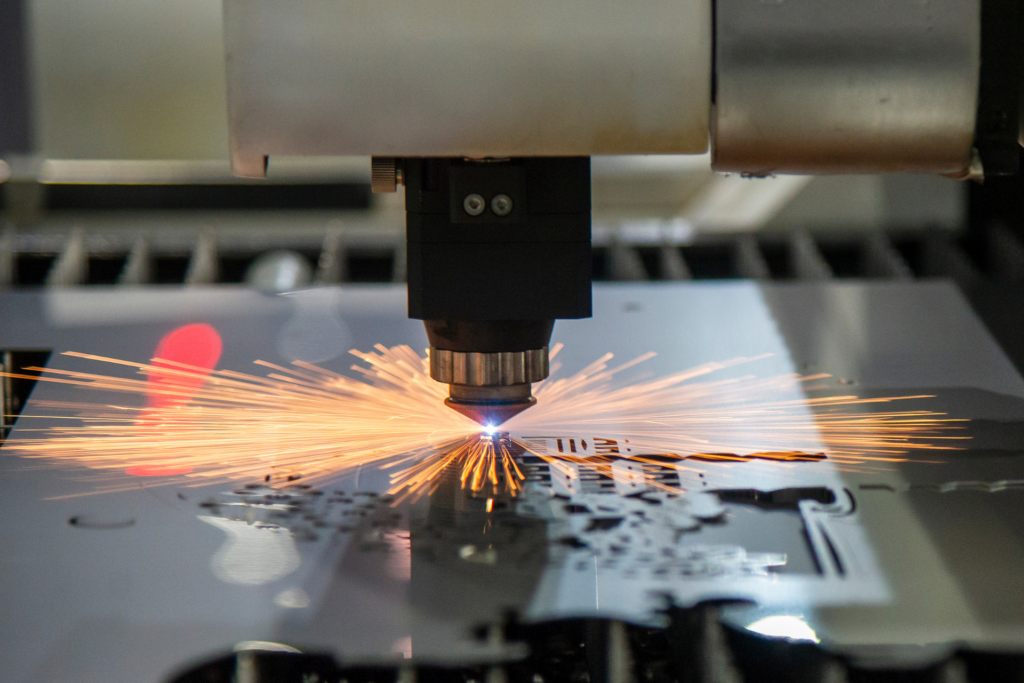

1. Laser Cutting

Ideal for detailed patterns, laser cutting uses high-energy beams to slice through metal, providing clean results without physical contact.

2. Waterjet Cutting

A versatile method that uses high-pressure water combined with abrasive materials. Learn more about this technique here.

3. Plasma Cutting

Using ionized gas, plasma cutting is perfect for thick metal sheets, delivering rapid cuts with unparalleled precision.

Factors Influencing Precision

Ensuring precision in metal cutting involves understanding several factors:

Material Type

The inherent properties of metals influence the choice of cutting technique.

Equipment Quality

Modern equipment equipped with advanced features ensures high precision. Explore more about equipment at ScienceDirect.

Operator Expertise

An experienced operator ensures that machines are used to their fullest potential, maximizing the accuracy of cuts.

The Future of Precision Cutting in Prototyping

As technology evolves, the potential of precision cutting expands. Innovations continue to enhance accuracy, efficiency, and speed, which are crucial in fast-paced sectors.

Manufacturers are constantly adapting to integrate cutting-edge tools and methodologies, setting new standards in prototyping. Stay updated with advances at our official site.

FAQs

What metals can be cut with precision?

Most metals, including aluminum, steel, and titanium, can be cut precisely using advanced techniques.

Why is precision important in prototyping?

Precision ensures that prototypes are exact representations of final products, crucial for detecting design flaws early.

How does laser cutting differ from plasma cutting?

Laser cutting uses light to cut, offering fine detail, while plasma cutting uses gas, which is ideal for thicker materials.

In conclusion, precision metal cutting for prototyping is pivotal in crafting detailed, reliable, and functional models, critical in the journey from concept to market.

This article contains affiliate links. We may earn a commission at no extra cost to you.