The art of precision cutting plays a critical role in the aerospace industry. Manufacturing aerospace components requires unparalleled accuracy and precision, underscoring the importance of advanced precision cutting methods.Precision cutting for aerospace must adhere to stringent standards, ensuring each part is flawless and fits perfectly into its designated place. This is crucial for operational safety and performance efficiency.

In this article, we’ll delve into the essence of precision cutting for aerospace, exploring the nuances that make it indispensable in the manufacturing sector. The methods and tools utilized guarantee that every component meets the demanding requirements of aerospace engineering.

The Importance of Precision Cutting

Precision cutting is vital not just for the aesthetics of a component but for its functionality and efficiency. In the aerospace sector, where components have to withstand extreme conditions, each millimeter matters. With precision cutting techniques, manufacturers achieve the exact, minute details required for aircraft to function safely and optimally.

Technology in Aerospace Manufacturing

The integration of technology within aerospace manufacturing cannot be overstated. From CAD (Computer-Aided Design) to CAM (Computer-Aided Manufacturing), advances in technology have tremendously impacted the precision cutting industry. By maximizing accuracy and minimizing errors, these technological advances have propelled aerospace engineering to new heights.

Techniques in Precision Cutting for Aerospace

Understanding the different methods of precision cutting is essential for anyone involved in aerospace manufacturing. Employing the right techniques guarantees optimal results. Let’s explore a few common methods:

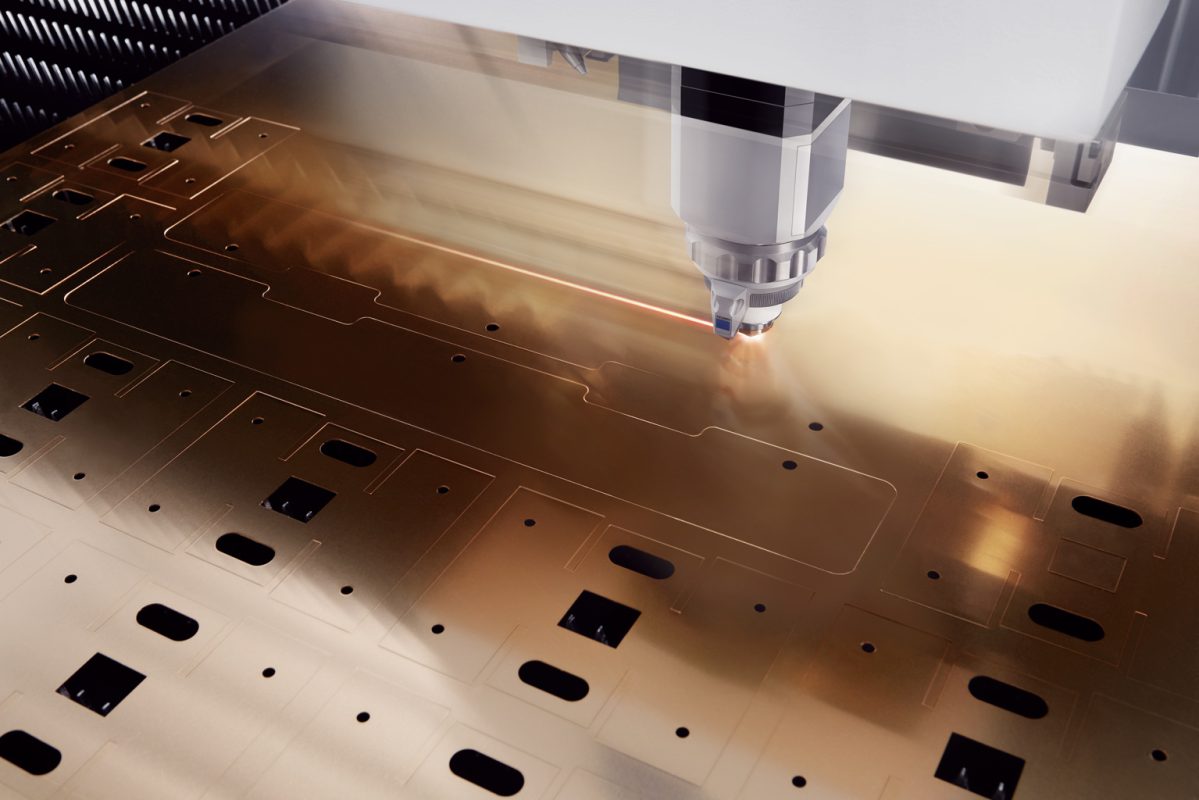

Laser Cutting

Laser cutting is revered for its precision and speed. Using a high-powered laser beam, this method ensures clean cuts and intricate detailing, ideal for the complex designs typical in aerospace components.

Waterjet Cutting

Waterjet Cutting involves using high-pressure water mixed with abrasives to slice through materials. This technique is famed for not altering the metal properties, making it a preferred method in the aerospace sector.

EDM (Electrical Discharge Machining)

EDM is integral for cutting hard materials where traditional cutting tools might falter. It is employed widely in aerospace to shape intricate components with high precision.

Advantages of Precision Cutting in Aerospace

The advantages of opting for precision cutting are manifold. Besides boosting manufacturing accuracy, it significantly reduces waste, supports sustainability, and lowers production costs. Precision methods empower engineers and manufacturers to materialize designs closer to their digital plans, enhancing production efficiency.

Moreover, this type of cutting ensures that all manufactured parts comply with safety standards, a critical component in aerospace engineering. Components crafted using precise techniques contribute directly to the overall reliability and longevity of aerospace vehicles.

Meeting Stringent Aerospace Standards

Every aerospace component has to meet strict industry regulations. By employing top-notch precision cutting techniques, manufacturers ensure compliance without sacrificing quality.

The Future of Precision Cutting in Aerospace

As technology continues to evolve, the future of precision cutting in the aerospace landscape looks promising. Integration of artificial intelligence, machine learning, and other innovative technologies into cutting processes promises unprecedented precision and efficiency levels.

Innovations and Opportunities

Future innovations might introduce self-calibrating tools, automatic error detection, and more nuanced AI-driven processes that will further heighten the reliability of precision cutting methods. These advances will redefine the boundaries of what is achievable within aerospace engineering, opening new opportunities for development and creativity.

Conclusion

In conclusion, precision cutting for aerospace is more than just a manufacturing requirementit’s a necessity. With its influence touching every corner of production and manufacturing quality assurance, it’s shaping the future of the aerospace industry.

For more on the various methods of precision cutting and their applications, visit Modern Metalworks’ extensive resources.

FAQ

What is precision cutting?

Precision cutting involves advanced techniques to slice materials with extreme accuracy, essential in industries requiring meticulous attention to detail, like aerospace.

How does precision cutting benefit aerospace manufacturing?

It ensures components meet strict safety and quality standards by delivering exact, reliable, and efficient manufacturing capabilities.

What are some technologies involved in precision cutting?

Technologies like CAD, CAM, and laser cutting are critical in enhancing manufacturing precision and reducing potential errors.

This article contains affiliate links. We may earn a commission at no extra cost to you.