In the modern industrial landscape, precision cutting and lean manufacturing have emerged as pivotal elements in enhancing production efficiency and product quality. These concepts are not only transformative but also essential for businesses aiming to remain competitive in a rapidly evolving market. By integrating advanced cutting techniques with streamlined manufacturing processes, companies can achieve remarkable results in terms of speed, accuracy, and cost-effectiveness.

Understanding Precision Cutting

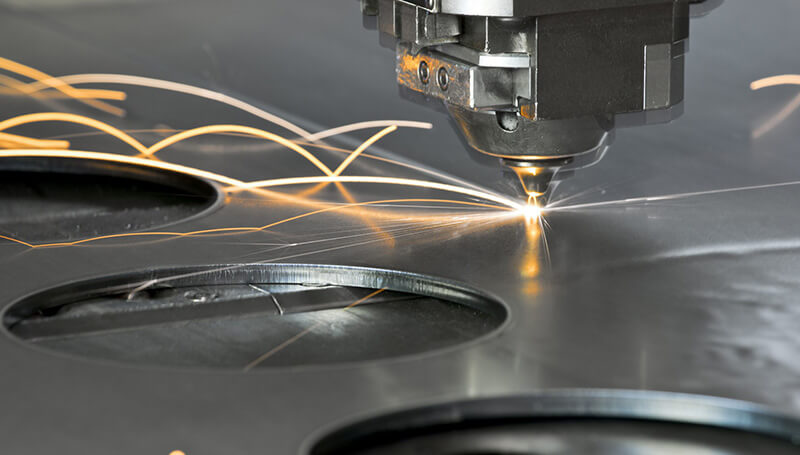

Precision cutting refers to the use of advanced machinery and techniques to cut materials with high accuracy. This method is crucial in industries where precision is paramount, such as aerospace, automotive, and electronics. The goal is to achieve exact dimensions and intricate details, reducing material waste and ensuring the highest quality of the final product.

Tools and Technologies

Various tools and technologies are employed in precision cutting. Laser cutters, CNC machines, and waterjet cutters are some of the most popular. These tools allow for high precision and repeatability, making them ideal for mass production. For more insights on how CNC compares to manual methods, visit our article on CNC vs Manual Cutting.

Advantages of Precision Cutting

The advantages of precision cutting include reduced waste, lower production costs, and improved product quality. By minimizing errors and material wastage, manufacturers can significantly cut down on costs while enhancing the overall quality of their products. For a deeper understanding, check out this guide to precision metal cutting.

Lean Manufacturing Principles

Lean manufacturing focuses on eliminating waste within manufacturing systems. By optimizing processes, lean manufacturing aims to enhance productivity and efficiency. This approach includes principles such as continuous improvement, respect for people, and the reduction of unnecessary waste.

Implementing Lean Strategies

Implementing lean strategies involves a thorough analysis of every step in the manufacturing process to identify and eliminate waste. Techniques such as Just-in-Time (JIT) production and Total Quality Management (TQM) are often used. To learn how different materials affect the process, visit our article on Cutting Stainless vs Mild Steel.

Benefits of Lean Manufacturing

The benefits of lean manufacturing are manifold. They include increased efficiency, reduced operational costs, improved customer satisfaction, and enhanced employee morale. By fostering a culture of continuous improvement, companies can sustain long-term growth and competitiveness.

Integrating Precision Cutting with Lean Manufacturing

The integration of precision cutting with lean manufacturing creates a powerful synergy that enhances the overall efficiency and effectiveness of production processes. This integration allows for the precise execution of lean principles, resulting in even greater reductions in waste and improvements in quality.

Case Studies and Real-World Applications

Many companies have successfully integrated precision cutting with lean manufacturing. These case studies demonstrate the potential benefits and provide valuable insights into the practical application of these concepts. For more detailed examples, explore our piece on Cutting Different Thicknesses.

Future Trends

The future of precision cutting and lean manufacturing is set to be shaped by technological advancements and increasing demands for sustainability. As industries continue to evolve, the adoption of these practices will likely become even more widespread, driving further innovation and efficiency.

Challenges and Considerations

Despite the numerous advantages, there are challenges associated with the implementation of precision cutting and lean manufacturing. These include the need for significant investment in technology and training, as well as the cultural shift required to fully embrace lean principles.

Overcoming Barriers

Overcoming these barriers involves a commitment to change and the willingness to invest in both technology and people. By addressing these challenges head-on, companies can successfully transition to more efficient and precise manufacturing processes.

Key Takeaways

The integration of precision cutting and lean manufacturing is a powerful strategy for improving efficiency and product quality. By understanding and applying these principles, companies can achieve significant competitive advantages.

FAQs

What is precision cutting?

Precision cutting is a technique used in manufacturing to cut materials with high accuracy and minimal waste.

How does lean manufacturing improve efficiency?

Lean manufacturing improves efficiency by eliminating waste and optimizing processes.

What are the benefits of integrating precision cutting with lean manufacturing?

The integration leads to enhanced efficiency, reduced waste, and improved product quality.

This article contains affiliate links. We may earn a commission at no extra cost to you.