In the world of manufacturing, choosing the right process is crucial to achieving efficiency and quality. Two common methods are metal stamping and forging. Understanding the differences between these processes can help manufacturers make informed decisions. This article explores the nuances of these two techniques, offering insights into their advantages and applications.

Understanding Metal Stamping

Metal stamping involves shaping metal using a press and a die. This process is ideal for producing complex shapes with precision. It is widely used in industries such as automotive, aerospace, and electronics. The ability to create intricate designs makes it a popular choice for high-volume production.

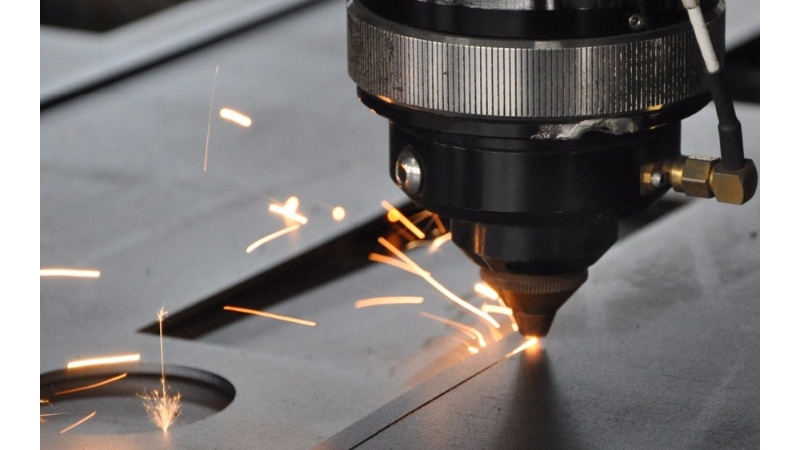

The Process of Metal Stamping

The metal stamping process begins with a flat sheet of metal. The sheet is then inserted into a stamping press where a die shapes it into the desired form. This process can include various techniques such as blanking, bending, coining, and embossing. The precision of metal stamping ensures consistent quality in every piece.

Advantages of Metal Stamping

- High precision and accuracy

- Cost-effective for large production runs

- Ability to produce complex designs

For more details on the benefits of metal stamping, visit this resource.

Exploring Forging

Forging is a process that involves shaping metal using compressive forces. This method is known for producing strong and durable parts, making it suitable for heavy-duty applications. Forging is often used in industries like construction and machinery.

The Process of Forging

In forging, a metal piece is heated and then hammered or pressed into shape. This process can be done using various techniques such as open-die forging, closed-die forging, and roll forging. The heat and pressure applied during forging enhance the metal’s structural integrity, resulting in robust components.

Advantages of Forging

- Produces strong and durable parts

- Enhances the metal’s structural integrity

- Suitable for heavy-duty applications

Comparing Metal Stamping vs Forging

When comparing metal stamping vs forging, several factors come into play. Each process has its strengths and is better suited for specific applications.

Cost Considerations

Metal stamping is generally more cost-effective for high-volume production due to its efficiency and lower material waste. On the other hand, forging may have higher initial costs but can be more economical for producing large, robust parts.

Strength and Durability

Forging produces parts with superior strength and durability, making it ideal for components that must withstand high stress and impact. In contrast, metal stamping is better suited for applications requiring precision and intricate designs.

Production Speed

Metal stamping is faster for producing large quantities of parts due to its automated nature. Forging, while slower, is preferred for custom or smaller batch production where strength is critical.

Applications of Metal Stamping and Forging

Both metal stamping and forging have their place in manufacturing. Metal stamping is commonly used for producing automotive components, electronic parts, and household appliances. Forging is favored for creating tools, engine parts, and structural components.

For more insights into metal stamping applications, check out this article.

Choosing Between Metal Stamping and Forging

The choice between metal stamping and forging depends on several factors, including the desired properties of the final product, production volume, and budget constraints. Manufacturers must weigh the benefits and limitations of each method to determine the best fit for their needs.

Considerations for Manufacturers

Manufacturers should consider the following when deciding between metal stamping and forging:

- Production volume and cost

- Required strength and durability

- Complexity of design

To learn more about choosing the right manufacturing process, read this guide.

Conclusion

In the debate of metal stamping vs forging, each method offers distinct advantages. Metal stamping excels in precision and cost-effectiveness for large-scale production, while forging provides unmatched strength and durability for heavy-duty applications. Understanding these differences can help manufacturers make informed decisions that enhance their production processes and product quality.

FAQ

What is the main difference between metal stamping and forging?

The main difference lies in the process. Metal stamping uses a press and a die to shape metal, while forging involves heating and compressing metal to achieve the desired shape.

Which process is more cost-effective?

Metal stamping is generally more cost-effective for high-volume production due to its efficiency and lower material waste.

What industries use metal stamping?

Metal stamping is widely used in industries such as automotive, aerospace, and electronics for producing complex and precise components.

This article contains affiliate links. We may earn a commission at no extra cost to you.