Steel is one of the most recycled materials in the world, valued for its strength, versatility, and the fact that it can be reused without losing its essential properties. Understanding how recycled steel is made reveals not only the environmental benefits but also the complex steps involved in transforming discarded metal into high-quality products, such as blades and beams. This guide walks through each stage of the process, from collection to the final shaping, and highlights why recycled steel remains a cornerstone of modern manufacturing and sustainability efforts.

The journey from scrap to finished steel involves careful sorting, advanced processing, and strict quality control. By using recycled steel, industries reduce energy consumption, minimize waste, and help conserve natural resources. For those interested in the broader context of metal reuse, the metal recycling process explained article provides a detailed look at the entire recycling chain.

Collecting and Sorting Scrap Metal

The first step in the recycled steel production process is gathering scrap from various sources. This includes old vehicles, demolished buildings, appliances, and industrial waste. Scrap yards and recycling centers play a crucial role in collecting and storing these materials before processing.

Sorting is essential to ensure that only ferrous metals—those containing iron—are selected for steel recycling. Magnets and advanced sensors help separate steel from non-ferrous metals and contaminants. Proper sorting improves the efficiency and quality of the final product.

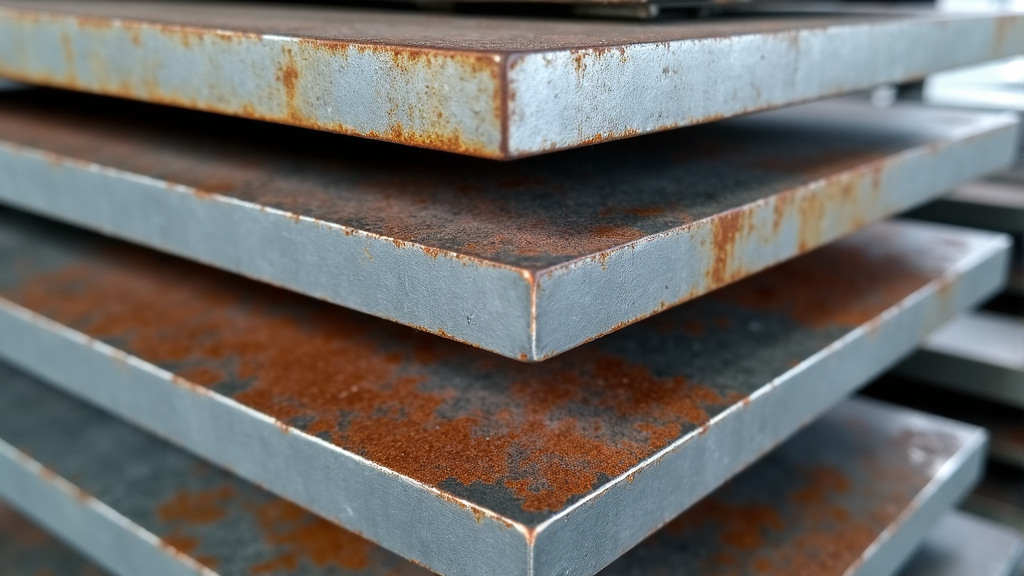

Processing and Shredding: Preparing Scrap for Melting

Once sorted, the scrap metal is cleaned and processed to remove impurities such as paint, plastics, and rubber. This step is vital for ensuring the quality of the recycled steel. Large pieces are cut down to manageable sizes, and powerful shredders break the metal into smaller fragments, increasing the surface area for efficient melting.

Shredding not only makes transportation easier but also ensures a more uniform feedstock for the furnace. For those interested in the machinery behind this stage, investing in a reliable shredder can make a significant difference in processing efficiency.

Melting and Refining: Turning Scrap into Liquid Steel

The prepared scrap is loaded into a furnace—either an electric arc furnace (EAF) or a basic oxygen furnace (BOF), depending on the facility. EAFs are commonly used for recycling because they can efficiently melt large quantities of scrap using high-voltage electric arcs.

During the melting process, temperatures reach up to 1,800°C (3,272°F), turning the metal into a molten state. Refining agents are added to remove remaining impurities and adjust the chemical composition. This ensures the resulting steel meets strict industry standards for strength and durability.

Forming and Shaping: From Molten Metal to Finished Products

After refining, the liquid steel is poured into molds to form ingots, slabs, or billets. These shapes are then processed further through rolling, forging, or extrusion to create beams, sheets, and blades. The versatility of steel allows it to be used in countless applications, from construction to precision tools.

Quality control is critical at this stage. Samples are tested for strength, hardness, and chemical composition to ensure the recycled steel meets the required specifications. This attention to detail is what allows recycled steel to perform as well as, or even better than, newly produced steel.

Environmental and Economic Benefits of Steel Recycling

Producing steel from recycled materials uses significantly less energy than making it from raw ore—up to 74% less, according to industry estimates. This reduction in energy consumption leads to lower greenhouse gas emissions and less strain on natural resources.

Economically, recycling steel supports a circular economy by creating jobs in collection, processing, and manufacturing. It also reduces the need for landfill space and decreases the demand for mining, which can have harmful environmental impacts.

For a deeper dive into the role of metal recycling in sustainable industry, the article on the importance of metal recycling in industry explores how these practices contribute to long-term environmental goals.

Applications of Recycled Steel in Modern Manufacturing

Recycled steel finds its way into a wide range of products, from structural beams in buildings to automotive parts and kitchen knives. Its consistent quality and reliability make it a preferred choice for manufacturers seeking both performance and sustainability.

The process described here ensures that recycled steel can be shaped into strong, durable blades and other high-performance items. If you’re interested in how these materials are used in various industries, the guide on how recycled metal is used in manufacturing offers practical examples and insights.

Types of Metals Suitable for Recycling

While steel is the most commonly recycled metal, other metals such as aluminum, copper, and brass are also valuable. Each type requires specific handling and processing methods. For a comprehensive overview of what metals can be recycled, see this guide to recyclable metals.

Understanding the differences between recycled and virgin metals can help businesses and consumers make informed choices. The article on the difference between recycled and virgin metal explains the key distinctions and benefits.

Frequently Asked Questions

What are the main steps in the steel recycling process?

The process includes collecting and sorting scrap, cleaning and shredding, melting and refining in a furnace, and finally forming and shaping the steel into new products. Each step is designed to maximize efficiency and quality.

Is recycled steel as strong as new steel?

Yes, recycled steel retains its original strength and durability. Through careful refining and quality control, it meets or exceeds the standards required for demanding applications such as construction and blade manufacturing.

How does recycling steel benefit the environment?

Recycling steel conserves natural resources, reduces energy use, and cuts greenhouse gas emissions. It also minimizes landfill waste and supports a more sustainable industrial system.

Can all types of steel be recycled?

Most steel products can be recycled, including those from vehicles, appliances, and construction materials. However, items with excessive contamination or certain coatings may require additional processing.

Where can I learn more about scrap metal processing?

For a detailed look at how scrap metal is prepared for reuse, visit the article on how scrap metal is processed.