The automotive industry produces millions of vehicles each year, and with every car that reaches the end of its life, a significant amount of material is left behind. Understanding how car parts are recycled is crucial for reducing waste, conserving resources, and supporting a more sustainable future. This guide explores the process of reclaiming and reusing automotive components, highlighting the environmental and economic benefits of these practices.

Recycling vehicle components not only diverts materials from landfills but also reduces the need for new raw materials. By breaking down old cars and recovering valuable metals, plastics, and other substances, the industry can minimize its environmental footprint. For those interested in broader metal reclamation, learning about steps in metal recycling provides additional context on how these processes fit into the larger recycling ecosystem.

The Journey of End-of-Life Vehicles

When a vehicle is no longer roadworthy, it typically enters the recycling stream through specialized facilities known as auto dismantlers or salvage yards. These businesses are equipped to safely handle hazardous materials and efficiently strip vehicles of reusable and recyclable parts. The process begins with a thorough inspection to determine which components can be salvaged, resold, or sent for further processing.

Fluids such as oil, coolant, and brake fluid are carefully drained and disposed of or recycled according to environmental regulations. Batteries, tires, and electronic components are removed to prevent contamination and to enable specialized recycling. This initial stage is essential for maximizing the recovery of valuable materials while minimizing environmental risks.

Sorting and Processing Automotive Materials

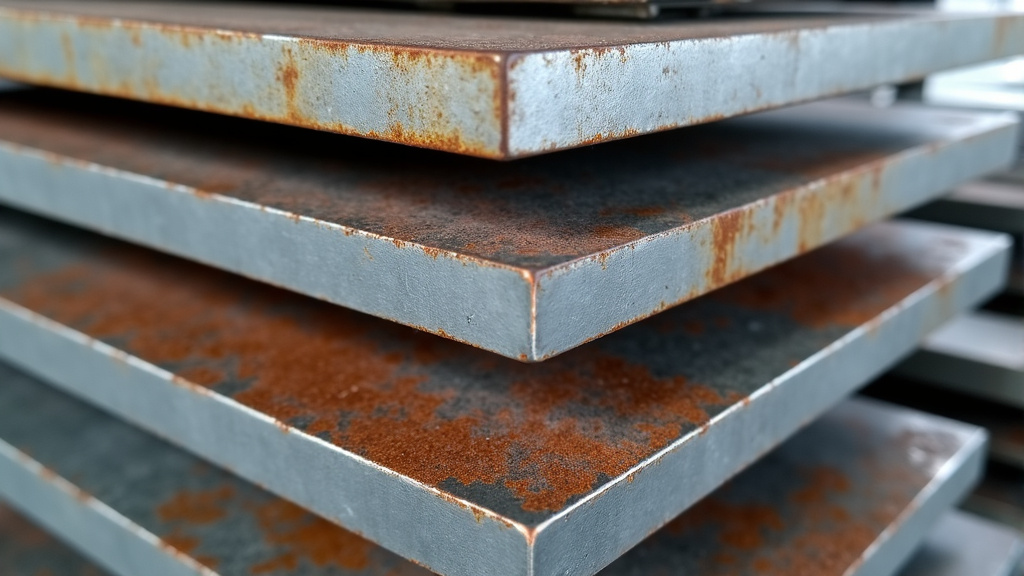

After hazardous substances and reusable parts are removed, the remaining vehicle shell is processed for material recovery. The shell, primarily composed of metals, is crushed and sent to shredding facilities. Here, powerful machines break down the vehicle into smaller pieces, making it easier to separate different materials.

At this point, advanced sorting technologies come into play. Magnets extract ferrous metals like steel, while eddy current separators and other methods help isolate non-ferrous metals such as aluminum and copper. Non-metallic materials, including plastics and glass, are also sorted for appropriate recycling streams. For a deeper dive into these techniques, see how how metals are sorted for recycling using modern methods and technologies.

Recycling Key Car Components

Not all parts follow the same recycling path. Here are some of the most commonly recycled automotive components and how they are processed:

- Metals: Steel and aluminum make up a large portion of a vehicle’s mass. These metals are melted down and reformed into new products, drastically reducing the need for virgin ore extraction. For more on this, discover how recycled steel is made from scrap to finished goods.

- Plastics: Bumpers, dashboards, and interior panels are often made from recyclable plastics. These are shredded, cleaned, and processed into pellets for manufacturing new plastic items.

- Glass: Windshields and windows are crushed and cleaned, then used in the production of new glass products or as aggregate in construction materials.

- Batteries: Lead-acid batteries are sent to specialized facilities where lead and plastic are separated and recycled. Newer lithium-ion batteries require different handling but are increasingly being recycled as technology advances.

- Tires: Old tires can be repurposed as fuel, playground surfaces, or raw material for new rubber products.

Environmental and Economic Benefits of Automotive Recycling

The benefits of reclaiming vehicle components extend far beyond waste reduction. By recovering metals and other materials, energy consumption and greenhouse gas emissions are significantly lowered compared to producing new materials from scratch. According to research on the environmental impact of metal recycling, recycling metals from vehicles helps conserve natural resources and reduces the overall carbon footprint of the automotive sector.

Economically, the industry supports thousands of jobs in dismantling, processing, and manufacturing. Recycled materials are often less expensive than virgin resources, helping manufacturers control costs and offer more affordable products to consumers.

Challenges and Innovations in Car Part Recovery

While the process of reclaiming vehicle components has advanced significantly, several challenges remain. Modern vehicles contain an increasing number of electronic parts and composite materials, which can be more difficult to separate and recycle efficiently. Additionally, ensuring that hazardous substances are properly managed is critical for both environmental and worker safety.

Innovations in sorting technology, automation, and chemical recycling are helping to address these issues. For example, new methods for recovering rare earth elements from electric vehicle batteries are emerging, and improved shredding equipment enables more precise material separation. For those interested in the broader context, learning how aluminum is recycled for new products provides insight into the versatility of metal recycling technologies.

Maximizing the Value of Recycled Car Parts

The value of automotive recycling is maximized when parts are reused directly, rather than being melted down or shredded. Engines, transmissions, and body panels in good condition can be refurbished and sold as replacement parts, extending their lifespan and reducing demand for new manufacturing.

For materials that cannot be reused, efficient recycling ensures that as much value as possible is extracted. This closed-loop approach supports a circular economy, where materials are kept in use for as long as possible before being responsibly recycled.

If you are interested in the broader benefits of metal reclamation, the advantages of recycling metals include energy savings, reduced emissions, and conservation of natural resources.

Frequently Asked Questions

What happens to the fluids and hazardous materials in old cars?

Before a vehicle is dismantled, all fluids—such as oil, coolant, and brake fluid—are drained and collected for safe disposal or recycling. Hazardous materials like batteries and airbags are removed and processed separately to prevent environmental contamination.

Can all car parts be recycled?

Most components, especially metals, plastics, and glass, can be recycled. However, some composite materials and certain electronics may be more challenging to process. Advances in recycling technology are making it possible to reclaim a greater variety of materials from end-of-life vehicles.

Why is recycling car parts important for sustainability?

Reclaiming automotive components reduces landfill waste, conserves natural resources, and lowers greenhouse gas emissions. It also supports a circular economy by keeping valuable materials in use and reducing the need for new raw material extraction.