Cutting aluminum with high accuracy is a critical task in the industrial manufacturing domain. To achieve top-notch results, it’s essential to understand the various methods utilized in this process. In this detailed guide, we will explore the techniques and tools that ensure both precision and effectiveness when cutting aluminum, helping manufacturers meet stringent industrial standards.

Introduction to Aluminum Cutting

Chiefly used in diverse applications, aluminum is a versatile material owing to its strength, light weight, and resistance to corrosion. The objective of cutting aluminum with high accuracy not only enhances the functionality of the product but also optimizes material usage and cost efficiency. As such, it’s crucial for manufacturers to comprehend the essentials and nuances involved in precision cutting.

Why High Accuracy Matters

In industrial manufacturing, the accuracy of cuts exemplifies the quality of the final product. Poor cutting techniques may lead to waste, increased costs, and ultimately, dissatisfied customers. High accuracy in cutting aluminum is vital for ensuring the dimensional integrity and performance of components. Hence, choosing precise methods and tools is paramount.

Different Methods of Cutting Aluminum

Several cutting methods, ranging from traditional to advanced techniques, are employed across the industry. Each method has its merits and is chosen based on specific needs and material properties.

Sawing and Shearing

Sawing involves the use of continuous-tooth blades that move continuously, known for ease and speed when cutting aluminum. Shearing, on the other hand, is suitable for cutting aluminum into sheets. These methods are noted for their simplicity and economic advantages but may lack the precision needed for complex designs.

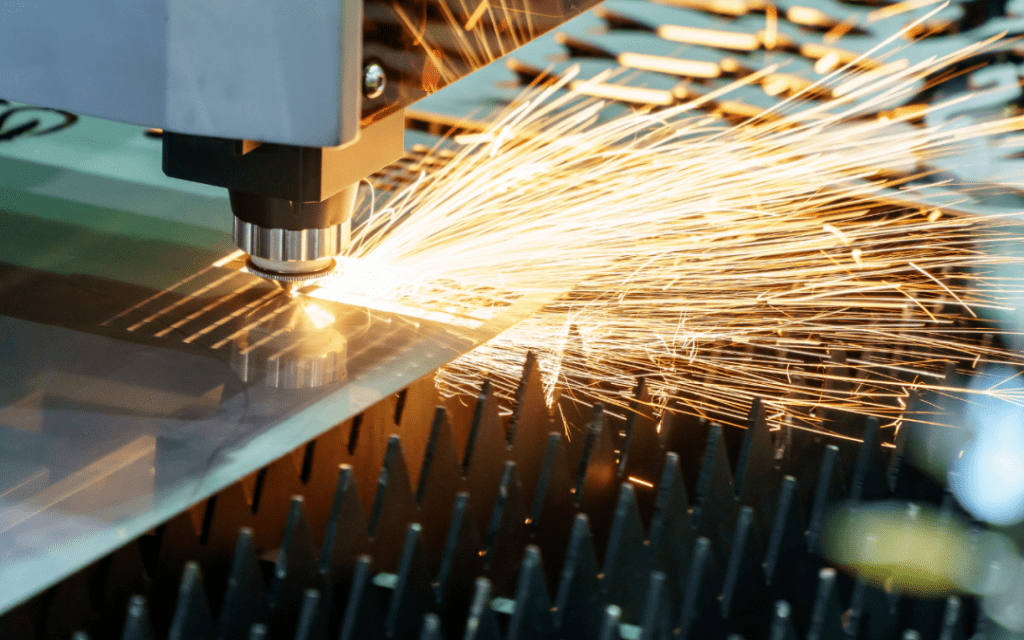

Laser Cutting Technology

Laser cutting is renowned for its precision. This technique utilizes a focused laser beam to melt or burn through metal, achieving intricate shapes with minimal error. Its versatility allows the creation of complex patterns with excellent edge quality.

Advanced Technologies in Aluminum Cutting

The evolution of technology has led to innovative solutions in cutting aluminum, particularly in achieving higher accuracy and improved efficiency.

Waterjet Cutting Techniques

Waterjet cutting employs a high-pressure stream of water mixed with abrasive substances to cut materials. This method is favored for its ability to cut without affecting the material’s properties due to heat. For further insights, consider visiting this introduction to waterjet metal cutting.

CNC Machining Applications

CNC (Computer Numerical Control) machines offer unparalleled precision by utilizing computer-guided systems to direct cutting tools. Ideal for high-volume production runs, CNC machines ensure repeatability and exactness. This technology defines the modern standard for accuracy in metal cutting.

Benefits of Intricate Tolerances

Understanding tolerances is crucial when seeking high accuracy. Tighter tolerances result in products that fit and function better, reducing assembly issues. Precision-cut components allow seamless integration into larger systems, reducing wear over time.

Tools and Equipment for Precision Cutting

Selection of the right tools and equipment is critical for achieving high accuracy in aluminum cutting.

Precision Saws and Blades

Choosing the right saw blades, such as diamond-coated or carbide-tipped blades, enhances accuracy and longevity. These specialized blades cut faster and stay sharper longer, contributing to an efficient process.

Advanced Machinery and Its Benefits

Advanced machinery such as CNC lasers provides distinct advantages in cutting aluminum. These machines offer automated precision, resulting in less material waste and higher-quality finishes. Read more on various cutting methods available today.

Utilizing CAD/CAM Systems

Computer-Aided Design and Manufacturing (CAD/CAM) systems allow accurate planning and design before physical cutting occurs. Implementing CAD/CAM systems ensures the reduction of errors and perfect replication of designs.

Ensuring Safe and Efficient Operations

Safety and efficiency are paramount in cutting aluminum. Always ensure equipment is well-maintained and operators are properly trained to reduce risks associated with machinery.

Operator Training and Expertise

Training workers in the latest techniques and machinery ensures high levels of productivity and safety. Competent operators reduce the likelihood of errors, increasing precision and reducing costs.

Maintenance of Cutting Tools and Machinery

Regular maintenance of machinery and sharpening of cutting tools prolong their lifespan and reliability. Ensuring machines are calibrated and blades are sharp contributes to continued accuracy in cuts.

Conclusion

Achieving high accuracy in cutting aluminum is a composite of employing the right methods, advanced technologies, and skilled operators. Successful implementation in industrial manufacturing leads not only to superior products but also cost efficiency and customer satisfaction.

FAQs

What are the traditional methods of cutting aluminum?

Traditional methods include sawing and shearing, which are cost-effective but may lack in precision when compared to advanced technologies.

How does technology enhance precision in aluminum cutting?

Advanced technologies like laser cutting and CNC machining allow for high precision and intricate designs through automation and computer-guided systems.

Why is waterjet cutting preferred for some applications?

Waterjet cutting doesn’t alter the metal’s properties due to heat, making it suitable for materials that might be negatively affected by high temperatures.

For more insights into precision metal cutting techniques, you can visit an external resource on Precision Cutting Techniques.

This article contains affiliate links. We may earn a commission at no extra cost to you.