In the world of manufacturing, consumer electronics metal stamping plays a pivotal role in creating the intricate components that power our everyday devices. From smartphones to home appliances, metal stamping is at the heart of the production process. This article aims to delve into the details of this essential manufacturing technique, providing insights that resonate with industrial manufacturers.

What is Metal Stamping?

Metal stamping is a process where flat sheet metal is shaped into specific forms using a stamping press. This technique is commonly used to manufacture parts for various electronic devices. The process involves placing the metal sheet into a press where a tool and die surface forms the metal into the desired shape.

Importance of Metal Stamping in Consumer Electronics

In the consumer electronics industry, metal stamping is indispensable. It allows manufacturers to produce high-quality parts efficiently and cost-effectively. The precision and speed of metal stamping make it ideal for producing the complex components found in electronic devices.

Advantages of Metal Stamping

One of the key advantages of metal stamping is its ability to produce large quantities of identical parts rapidly. This is crucial in the fast-paced world of electronics manufacturing. Additionally, metal stamping ensures high precision, which is necessary for the intricate parts used in consumer electronics.

Applications in Consumer Electronics

The applications of metal stamping in consumer electronics are vast. It is used to create components such as connectors, terminals, and shielding parts. These components are essential for the functionality and durability of electronic devices.

Metal Stamping Process

The metal stamping process involves several steps, each critical to the final product’s quality. Understanding these steps can help manufacturers optimize their production lines and ensure the highest quality parts.

Design and Tooling

The process begins with the design of the part and the creation of the tooling. The tooling must be precise to ensure the metal is formed correctly during stamping. High-quality tooling reduces defects and improves the efficiency of the stamping process.

Material Selection

Choosing the right material is essential in metal stamping. The material must be suitable for the intended application and capable of withstanding the stamping process without deforming. Common materials used in consumer electronics metal stamping include aluminum, copper, and stainless steel.

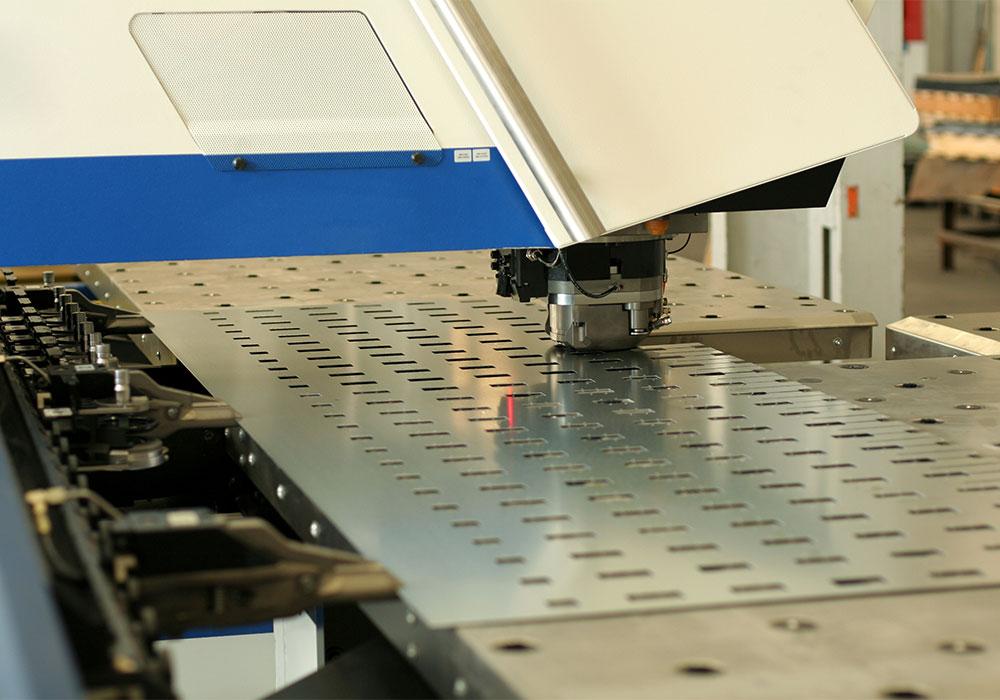

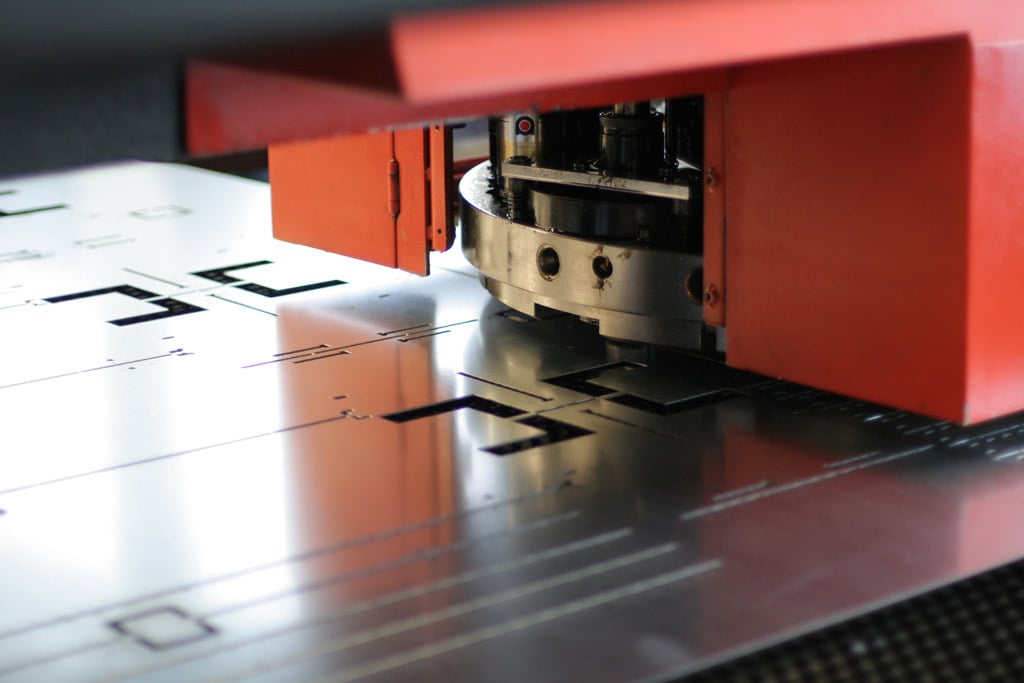

Stamping Press Operation

Once the design and tooling are in place, the stamping press is set up to begin production. The metal sheet is fed into the press, where it is stamped into the desired shape. The press operation must be carefully controlled to ensure consistent quality.

Quality Control in Metal Stamping

Quality control is a critical aspect of consumer electronics metal stamping. Manufacturers must implement rigorous inspection techniques to ensure that each part meets the required specifications. Regular inspections and testing help identify defects early and prevent costly rework.

are essential for maintaining high standards in metal stamping. These techniques enable manufacturers to detect and correct issues before they affect production. Implementing advanced quality control measures can significantly enhance the reliability of stamped parts.

Challenges in Metal Stamping

Despite its advantages, metal stamping also presents challenges. Manufacturers must address issues such as tool wear, material defects, and process inefficiencies to maintain high production standards. Continuous improvement and innovation are key to overcoming these challenges.

Tool Maintenance

Regular maintenance of stamping tools is crucial for preventing wear and tear. Effective maintenance practices can extend tool life and reduce downtime, resulting in more efficient production.

Material Quality

The quality of the material used in metal stamping directly impacts the final product. Manufacturers must source high-quality materials and perform thorough inspections to ensure consistency and reliability.

Future of Metal Stamping in Consumer Electronics

The future of consumer electronics metal stamping looks promising, with advancements in technology driving further innovation. Emerging technologies such as automation and digitalization are set to revolutionize the metal stamping process, making it more efficient and precise.

Automation

Automation is transforming the metal stamping industry, allowing for faster production and reduced labor costs. Automated systems can perform complex stamping operations with high precision, improving overall efficiency.

Digitalization

Digitalization is also playing a significant role in the evolution of metal stamping. Advanced software solutions enable manufacturers to design, simulate, and optimize stamping processes, leading to better quality and reduced waste.

Conclusion

In conclusion, consumer electronics metal stamping is an essential process in the manufacturing of electronic devices. It offers numerous advantages, including precision, efficiency, and cost-effectiveness. As technology continues to advance, the metal stamping industry is poised for exciting developments, promising even greater innovations in the future.

FAQs

What materials are commonly used in consumer electronics metal stamping?

Common materials include aluminum, copper, and stainless steel, each chosen for its specific properties and suitability for electronic components.

How does automation impact the metal stamping process?

Automation enhances the metal stamping process by increasing production speed, reducing labor costs, and improving precision and consistency.

Why is quality control important in metal stamping?

Quality control is crucial to ensure that each stamped part meets the required specifications, preventing defects and ensuring the reliability of electronic devices.

For more insights on the metal stamping process, check out this external resource.

This article contains affiliate links. We may earn a commission at no extra cost to you.