In the ever-evolving world of manufacturing, the debate over CNC vs. manual metal cutting continues. Both methods have their champions, each touting unique advantages. Understanding the core differences and applications is crucial for industrial manufacturers who aim to maximize efficiency and precision. This article explores these two metal cutting techniques in detail, guiding you towards making an informed decision.

What is CNC Metal Cutting?

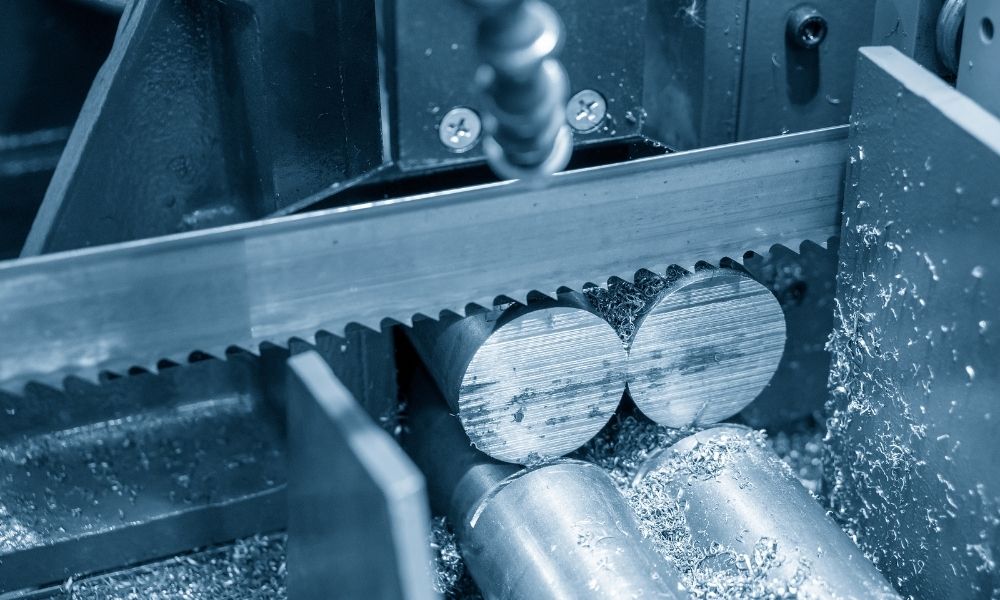

CNC, or Computer Numerical Control, refers to the automated control of machining tools and 3D printers by means of a computer. A popular technique in modern fabrication, CNC machines interpret CAD files to carry out precise and intricate cuts.

The Precision of CNC Technology

The primary advantage of CNC technology is its ability to produce consistent, intricate, and accurate cuts. Leveraging computer programming, these machines eliminate human error, resulting in high-quality outputs with a tight tolerance level. Learn more about tolerances in techniques like CNC on this tolerances guide.

Advantages of Using CNC

- Consistency and Precision: CNC machines deliver constant precision, crucial for complex designs.

- Efficiency: Capable of operating continuously, existing mainly to enhance production rates.

- Flexibility: Quick setup and reprogramming allow rapid transition between different tasks.

Understanding Manual Metal Cutting

Manual metal cutting has been the backbone of manufacturing with tools like lathes, mills, and drills operated by skilled artisans. This method requires a nuanced understanding of tools and materials.

The Art and Skill of Manual Cutting

Cutting metal manually is a craft mastered over time. Artisans rely on skill and experience to judge angles and apply appropriate force, keeping this technique relevant even amidst advancing technology.

The Benefits of Manual Techniques

- Craftsmanship: Offers a personalized touch, ideal for artistic and intricate designs.

- Cost-effective: Lower initial investment compared to purchasing CNC machinery.

- Versatility: Excellent for custom or low-volume projects.

Comparative Analysis: CNC vs. Manual Metal Cutting

When analyzing CNC vs. manual metal cutting, the choice often boils down to your specific needs.related methods like different cutting methods also play a role. Heres a breakdown of key factors:

Cost Considerations

While CNC machines have a higher upfront cost, their long-term efficiency and low labor costs can provide savings over time. Manual methods, on the other hand, offer lower initial costs, but may require more man-hours for completion.

Quality and Precision

CNC technology often outperforms manual methods in precision and quality consistency. However, manual artisanship can shine in unique, detail-oriented projects.

Speed and Volume

If speed and high production volume are priorities, CNC is a preferable choice. Conversely, manual methods can be ideal for smaller, deliberate productions.

Real-World Applications of Both Methods

Applications of CNC and manual cutting techniques are vast and varied. CNC methods are frequently applied in automotive, aerospace, and electronics industries. Manual techniques can be prominently found in artisanal crafts and custom metalwork.

Cross-Industry Usage

In industries dependent on precision metal cutting, the choice of technique significantly impacts the production line’s efficiency and quality.

Future Trends in Metal Cutting

As technology advances, the future of metal cutting trends towards smart manufacturing practices and integration of AI with CNC. Enhanced automation continues to drive the industry towards more sophisticated capabilities.

The Rise of Hybrid Systems

Some experts predict a rise in hybrid systems, combining the precision of CNC with the adaptability of manual methods. Such systems will likely revolutionize metal cutting by optimizing both efficiency and customization.

Technological Considerations

Technological breakthroughs continue to reshape the landscape for both CNC and manual metal cutting systems, with hybrid systems on the horizon.

Integrating Artificial Intelligence

AI has the potential to further increase efficiency and precision in CNC systems. Developers are focusing on creating smarter systems to anticipate issues and suggest real-time solutions.

Conclusion: Making the Right Choice

In conclusion, selecting between CNC and manual metal cutting depends on various factors specific to your business needs. Understanding each method’s strengths and limitations is key. Industrial manufacturers should weigh their specific requirements, budget constraints, and desired output to make an informed decision. You might also find this external guide to metal cutting methods insightful.

FAQ Section

What is the lifespan of a CNC machine?

The lifespan of a CNC machine typically ranges from 15 to 20 years with regular maintenance.

Can manual cutting techniques be automated?

While not traditionally automated, some advancements aim to integrate automation with manual techniques to enhance efficiency without losing the artisan touch.

Which method is more eco-friendly?

Generally, CNC machines tend to be more energy-efficient and produce less waste, making them a more environmentally friendly option compared to some manual methods, though sustainable practices in both can significantly reduce environmental impact.

This article contains affiliate links. We may earn a commission at no extra cost to you.