In our ever-evolving world, technology is constantly advancing, leading to remarkable achievements in various sectors. One such advancement is the applications of precision cutting which has transformed numerous industries. It plays a vital role in enhancing productivity, accuracy, and efficiency in manufacturing and other sectors.

Precision cutting involves the use of different techniques to accurately slice materials with minimal waste. This article will delve into the broad spectrum of industries where precision cutting finds its applications, offering significant benefits.

What is Precision Cutting?

Precision cutting refers to various methods used to cut materials into precise shapes and sizes. The approach ensures minimum errors and waste, facilitating efficient production processes. It is crucial in industries that require meticulous attention to detail and high-quality components.

To better understand precision cutting, consider reading more about precision metal cutting.

Key Techniques in Precision Cutting

There are several methods employed in precision cutting, each tailored to specific material types and industrial requirements. Lets explore some prominent techniques:

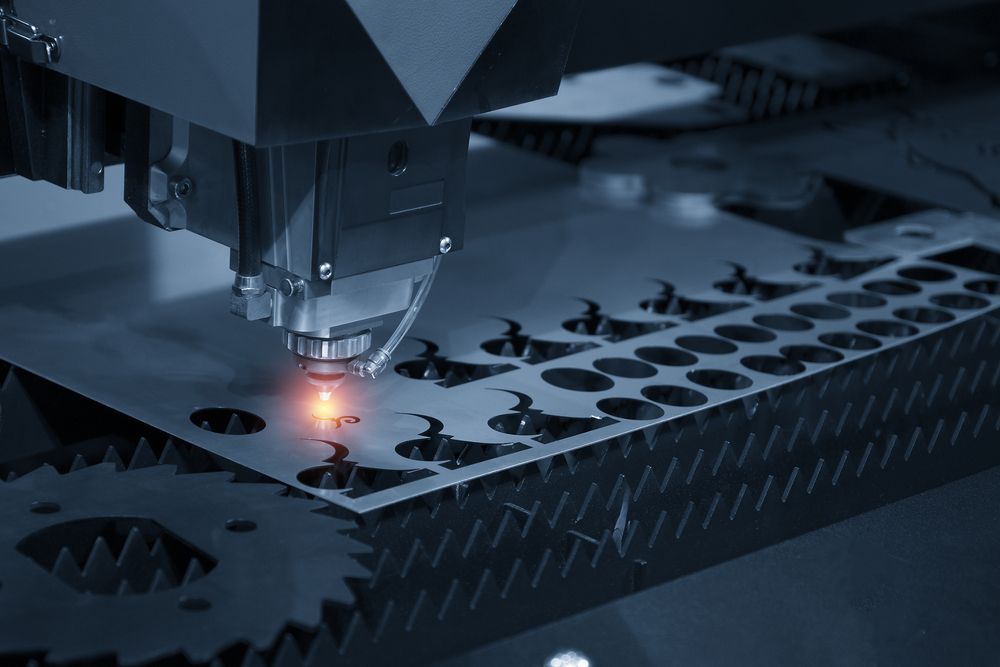

Laser Cutting

Laser cutting uses concentrated light beams to slice through materials accurately. It is ideal for metals, plastics, and fabrics, offering clean and precise edges. This technique is popular in automotive, aerospace, and textile industries.

For a deeper dive into various methods, visit types of precision cutting methods.

Waterjet Cutting

Waterjet cutting utilizes high-pressure streams of water, sometimes mixed with abrasive materials, to cut through workpieces. Its known for its cool cutting process, which prevents heat distortion. The method is widely applied in industries like metal fabrication and glass cutting.

Find out more on waterjet metal cutting.

Plasma Cutting

Plasma cutting uses ionized gas to melt and expel metal along the cut path. This method is excellent for cutting thick and electrically conductive materials. Its commonly applied in shipbuilding and construction industries.

EDM Cutting

Electrical Discharge Machining (EDM) cuts materials using electrically charged wire. Its highly suited for intricate and delicate components, often used in tool and die manufacturing.

Industrial Applications of Precision Cutting

Automotive Industry

Precision cutting is indispensable in the automotive industry. It ensures the production of high-accuracy parts, crucial for safety and performance. Precision cutting allows manufacturers to create components with tight tolerances, enhancing vehicle efficiency.

Learn how precision cutting impacts automotive applications through this external resource.

Aerospace Industry

In aerospace, the demands for safety and precision are paramount. Precision cutting techniques allow for the creation of lightweight, resilient, and accurately dimensioned parts, such as turbine blades and structural components, that withstand extreme conditions.

Medical Industry

In the medical field, devices and instruments must meet stringent standards. Precision cutting facilitates the manufacturing of surgical tools and implants with exact specifications, improving patient outcomes and safety.

Electronics Industry

Electronics require microscale components that maintain performance and reliability. Precision cutting allows for the production of miniaturized parts, essential for consumer electronics, semiconductors, and circuit boards.

Check out how precision manufacturing processes evolve in electronics within this blog article.

Benefits of Precision Cutting

Enhanced Quality

Precision cutting ensures high-quality finishes, reducing the need for post-processing. The accuracy of cuts results in superior product quality and increased customer satisfaction.

Efficiency and Cost-effectiveness

Automating precision cutting reduces material waste and labor costs, boosting overall production efficiency. Businesses benefit from lower operational costs and quicker turnaround times.

Design Flexibility

Precision cutting supports complex and innovative designs, allowing manufacturers to explore new possibilities and designs that were previously unattainable.

Environmental Considerations

Many precision cutting techniques are environmentally friendly, minimizing emissions and energy consumption, contributing to sustainable manufacturing practices.

Conclusion

The applications of precision cutting are extensive and impactful across various industries. As technology advances, industries continue to integrate precision cutting techniques, driving innovation and enhancing productivity. From automotives to aerospace, precision cutting ensures quality, efficiency, and sustainability, which are crucial for maintaining competitive advantage in today’s market.

For further insights into precision cutting techniques, consider exploring the tolerances in precision cutting.

Frequently Asked Questions (FAQs)

What materials can be cut using precision cutting techniques?

Precision cutting can handle a wide range of materials, including metals, plastics, glass, and composites. The technique depends on the materials properties and the required outcome.

Why is precision cutting important in manufacturing?

Precision cutting is vital for achieving high-quality products with exact specifications. It enhances efficiency, reduces waste, and supports complex designs, aligning with modern manufacturing demands.

How does precision cutting contribute to sustainability?

By minimizing waste and energy consumption, precision cutting supports environmentally friendly manufacturing. It also allows for the creation of lightweight structures, reducing material usage and improving energy efficiency.

This article contains affiliate links. We may earn a commission at no extra cost to you.