In the realm of metal manufacturing, a fundamental question often arises: what is precision metal cutting? This essential process is crucial for industrial manufacturers who demand high-quality and precise cuts every time. As we delve deeper into this topic, we’ll uncover how precision machining techniques have revolutionized the industry, setting new standards for accuracy and efficiency.

Understanding the Basics of Precision Metal Cutting

The term precision metal cutting refers to the highly accurate and precise process of cutting metals. It is a critical operation that ensures the production of parts with exact dimensions and tight tolerances. Generally, this technique is employed in industries where high levels of accuracy are required, such as aerospace, automotive, and medical industries.

Importance of Precision in Manufacturing

Precision in metal cutting is not just about aesthetics; it reduces waste and ensures that parts fit together perfectly. This level of accuracy is indispensable in maintaining the integrity of a products functionality. By using precision cutting methods, manufacturers can produce parts that meet stringent specifications and maintain high-quality standards.

Popular Methods Used in Precision Metal Cutting

Various methods are employed to achieve precision in metal cutting. Some of the most popular techniques include:

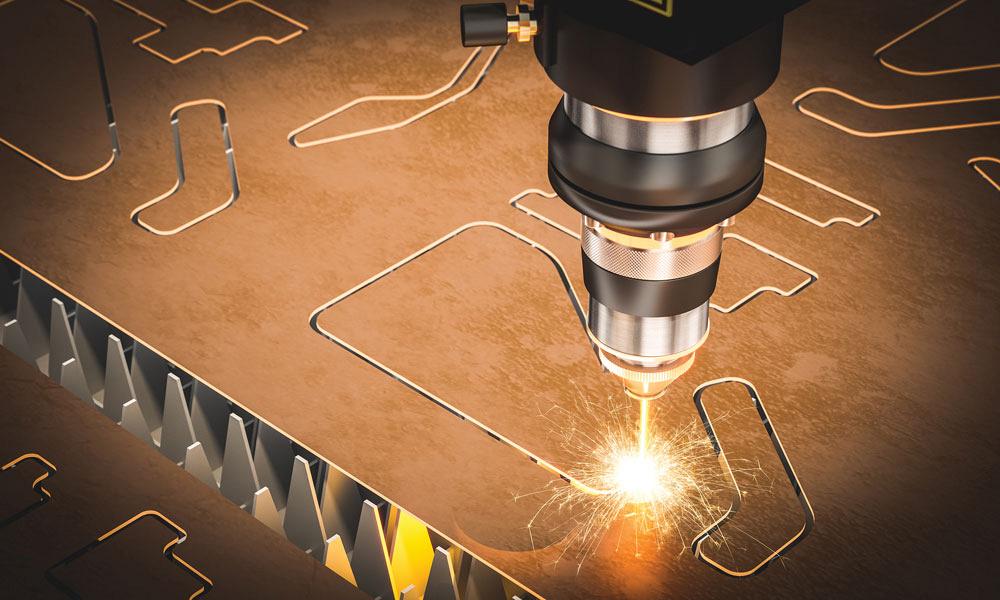

- Laser cutting This process uses a laser to cut material with high precision and accuracy, often resulting in clean cuts with a smooth finish.

- Waterjet cutting An abrasive waterjet can cut through different types of metals without generating heat, preserving the structural integrity of the metal.

- CNC machining Computer Numerical Control (CNC) machines are programmable robots used to achieve precise measurements and repeatable cuts.

Key Advantages of Precision Metal Cutting

Industrial manufacturers gain numerous benefits from precision metal cutting, which significantly enhances their operational efficiency and product quality.

Improved Product Quality

Precision cutting results in a superior product with improved quality. By providing exact cuts, the end product requires less finishing work, reducing lead times and increasing productivity.

Cost Efficiency

While precision metal cutting might initially seem costlier, the reduction in waste and rework ultimately results in greater cost efficiency. The optimized use of materials and time leads to cost-effective production cycles.

Versatility Across Industries

The versatility of precision cutting techniques makes them applicable across diverse industries, ranging from electronics to heavy machinery, ensuring consistent performance and reliability.

Challenges in Precision Metal Cutting

Despite its numerous benefits, precision metal cutting is not without challenges. These include equipment maintenance, operator skill requirements, and the need for continual technological updates to stay ahead in the industry.

Equipment Maintenance

The machinery used in precision metal cutting requires regular maintenance to ensure optimal performance. This includes calibration, part replacements, and preventive maintenance checks.

Skill Requirements

Operating precision cutting machinery demands a high level of skill. Continuous training and upskilling are necessary for operators to keep up with evolving technology.

Future Trends in Precision Metal Cutting

The industry is rapidly evolving with advancements in technology. Innovations such as AI and machine learning are poised to enhance precision and efficiency in metal cutting dramatically.

Incorporating AI for Enhanced Precision

Artificial Intelligence plays a pivotal role in optimizing precision metal cutting processes by offering real-time monitoring and adjustments, further enhancing accuracy and reducing downtime.

For more insights, you can visit modern-metalworks.com to see how AI is integrated into precision cutting.

Sustainable Practices

There is a growing emphasis on sustainability in manufacturing. Precision metal cutting plans to integrate eco-friendly practices, reducing material waste and energy consumption.

Conclusion

The realm of precision metal cutting offers industrial manufacturers unparalleled advantages in producing high-quality, reliable products. As technology evolves, we anticipate even more enhancements in efficiency and sustainability. Understanding and leveraging these cutting-edge techniques will be crucial for manufacturers aiming to maintain their competitive edge in the market.

For more detailed explanations and case studies on precision cutting advancements, check out a short guide to precision metal cutting.

FAQs on Precision Metal Cutting

What industries benefit the most from precision metal cutting?

Industries like aerospace, automotive, medical, and electronics benefit greatly due to the need for high precision in their components.

Why is precision important in metal cutting?

Precision ensures parts fit together accurately, reducing material waste and enhancing product quality.

What are the challenges in precision metal cutting?

Challenges include the need for skilled operators, regular equipment maintenance, and adapting to technological advancements.

This article contains affiliate links. We may earn a commission at no extra cost to you.