In today’s rapidly evolving construction industry, the integration of modular architectural metal fabrication is reshaping the way buildings are designed and constructed. The concept of modular architecture, combined with the precision of metal fabrication, offers a dynamic and flexible approach to building design. But what exactly is modular architectural metal fabrication? Let us delve into this exciting world and explore how it is influencing modern construction practices.

The Basics of Modular Architecture

Modular architecture refers to the process of constructing a building using prefabricated sections or modules. These modules are manufactured in a factory setting and then transported to the construction site for assembly. The fundamental advantage of this approach is its ability to streamline the building process, reduce construction time, and ensure quality control.

The Role of Metal Fabrication

Metal fabrication involves the process of cutting, shaping, and assembling metal materials to create structures or components. In the context of modular architecture, metal fabrication plays a crucial role in producing the prefabricated modules. The use of metals such as steel and aluminum in module construction provides strength, durability, and versatility.

Advantages of Modular Architectural Metal Fabrication

There are numerous advantages to using modular architectural metal fabrication in construction projects. Firstly, it significantly reduces construction time. Since modules are prefabricated off-site, they can be manufactured simultaneously with site preparation, leading to a faster overall construction process.

Improved Quality Control

Another significant advantage is improved quality control. In a factory setting, stringent quality checks can be implemented, ensuring that each module meets high standards before reaching the construction site. This reduces the likelihood of defects and enhances the overall quality of the finished building.

Cost Efficiency

Cost efficiency is another compelling reason why many developers are turning to modular architectural metal fabrication. By reducing construction time and labor costs, projects can be completed within budget more easily. Additionally, the durability of metal components reduces maintenance costs over the building’s lifespan.

Design Flexibility

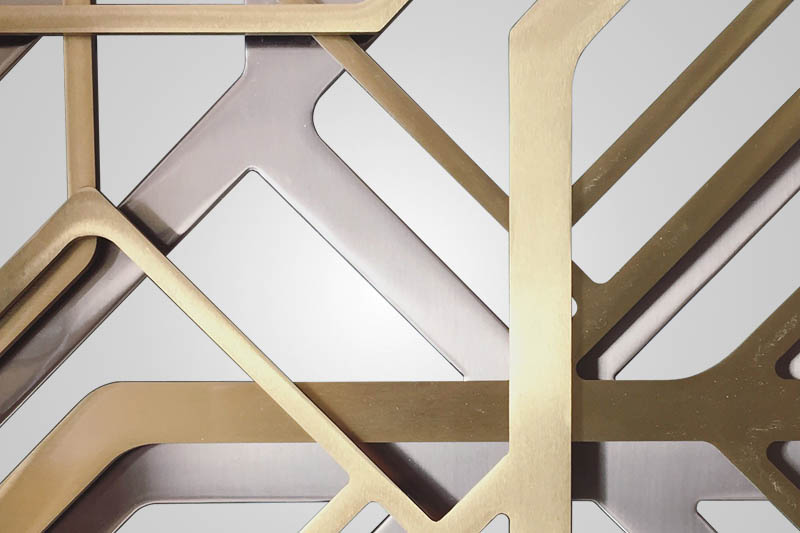

Modular architectural metal fabrication offers unparalleled design flexibility. Engineers and architects can create intricate and unique designs by combining different modules and materials. This flexibility allows for aesthetically pleasing and functional structures that meet diverse needs.

Applications of Modular Architectural Metal Fabrication

Modular architectural metal fabrication finds applications in a wide range of sectors, from residential to commercial and industrial projects. It is particularly beneficial in urban areas where space is limited, and construction speed is critical.

Residential Buildings

In residential construction, modular architecture allows for the efficient creation of housing units. The modules can be customized to suit various architectural styles, providing homeowners with unique living spaces.

Commercial Projects

For commercial buildings, modular architectural metal fabrication offers the advantage of rapid construction without compromising on quality. Retail spaces, offices, and hotels can be built quickly to meet market demands.

Industrial Facilities

In the industrial sector, the robustness and versatility of metal modules make them ideal for constructing factories, warehouses, and other facilities. The speed of construction ensures minimal disruption to business operations.

Challenges in Modular Architectural Metal Fabrication

While the benefits are significant, there are also challenges associated with modular architectural metal fabrication. One of the main challenges is the initial investment cost. Setting up a factory and the necessary equipment for module fabrication requires substantial capital.

Transportation and Logistics

Transportation and logistics can also pose challenges, as the prefabricated modules need to be transported to the construction site. This requires careful planning to ensure timely delivery and avoid damage during transit.

Design Limitations

Design limitations can arise due to the need to adhere to standard module sizes. While modular architecture offers flexibility, certain design constraints must be considered to ensure efficient transport and assembly.

Future of Modular Architectural Metal Fabrication

The future of modular architectural metal fabrication is promising, with ongoing advancements in technology and materials. Innovations in 3D printing and robotics are enhancing the precision and efficiency of module fabrication, opening new possibilities for design and construction.

Sustainability and Eco-Friendly Solutions

Sustainability is also a key focus for the future. The use of recyclable metals and energy-efficient manufacturing processes aligns modular architecture with environmental goals, making it an attractive option for eco-conscious developers.

Conclusion

In conclusion, modular architectural metal fabrication is revolutionizing the construction industry by offering a faster, cost-effective, and flexible approach to building design. While challenges exist, the advantages far outweigh them, making this approach increasingly popular in various sectors. With continued innovation and a focus on sustainability, the future of modular architecture looks bright.

FAQs

What is the primary material used in modular architectural metal fabrication?

The primary materials used are steel and aluminum, known for their strength and durability.

How does modular architecture benefit residential construction?

It allows for efficient construction of housing units, offering customizable and unique living spaces.

What are the main challenges in modular architectural metal fabrication?

The main challenges include initial investment costs and transportation logistics of prefabricated modules.

For further information on architectural metal fabrication, you can visit TBK Metal. Additionally, you can explore more about architectural metal features on our site. To understand the nuances of architectural metal patina, check out our detailed guide.

This article contains affiliate links. We may earn a commission at no extra cost to you.