Introduction to Precision Cutting

In today’s competitive industrial landscape, the need for precision cutting methods is more critical than ever. The demand for precise and accurate cutting techniques spans various industries, including aerospace, automotive, and electronics. Understanding types of precision cutting methods will enhance manufacturing practices, leading to increased efficiency and reduced waste. Let’s delve into the world of precision cutting, shedding light on the most advanced techniques available today.

Precision cutting is integral to modern industrial manufacturing. As we explore the types of precision cutting methods, it becomes evident how these techniques ensure products meet stringent quality standards. The impact of these methods is vast, influencing not only product quality but also production timelines and cost-efficiency.

1. Water Jet Cutting: Versatility Unleashed

Water jet cutting involves using a high-pressure stream of water, sometimes mixed with abrasive particles, to slice through materials. Its versatility lies in its ability to cut through almost any material, from metals to composites, without generating heat, ensuring the integrity of the material is maintained. Read more and understand its role in technical steel manufacturing technologies.

2. Laser Cutting: Precision at its Peak

Laser cutting is recognized for its precision and accuracy. This method uses a high-powered laser beam to cut materials, achieving clean edges and intricate designs. Laser cutting is ideal for industries requiring intricate parts, such as electronics and automotive sectors. Discover how laser cutting is pivotal in future steel production.

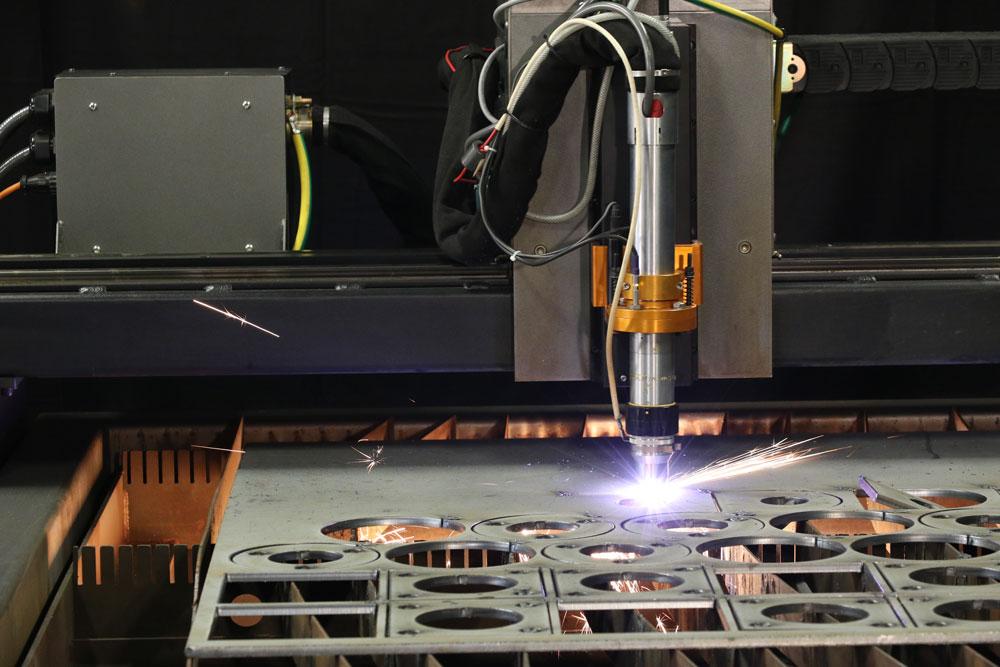

3. Plasma Cutting: Efficiency with Electricity

With plasma cutting, an electric arc is used to melt and eject material from the cut, making it suitable for conductive materials. This method is renowned for its speed and ability to cut thick materials, making it a favorite in metal fabrication and repair industries. Explore its applications in our section on global steel production trends.

4. EDM: Electrical Discharge Machining Explained

Electrical Discharge Machining (EDM) utilizes electrical discharges to shape materials, especially hard metals that are difficult to machine with traditional methods. EDM is used in situations where conventional cutting tools would not suffice, ensuring high precision and surface finish qualities. For more detailed insights, visit our page on steel stamping standards.

5. CNC Cutting: Computer-Controlled Accuracy

CNC cutting uses computer numerical control to automate machine tools. This method is highly accurate and repeatable, making it ideal for complex designs. The integration of CNC in manufacturing processes ensures efficiency and precision, saving time and resources. For more on automated solutions, refer to quality monitoring in metal industry.

Advantages of Precision Cutting Methods

Understanding the advantages of these cutting methods is essential for industrial manufacturers. Not only do they ensure high precision and accuracy, but they also contribute to material efficiency and cost-effectiveness. These methods reduce waste and improve the production flow, ultimately impacting the bottom line positively.

Choosing the Right Precision Cutting Method

Choosing the appropriate cutting method depends on several factors such as material type, thickness, desired accuracy, and production volume. Industrial manufacturers must evaluate their specific needs to select the most suitable cutting technique, ensuring optimal results for their production processes.

Environmental Impacts of Precision Cutting

Environmental considerations are increasingly important in industrial manufacturing. Several precision cutting methods, like water jet and laser cutting, offer sustainable options by minimizing material waste and improving energy efficiency. Learn more about sustainable practices in the industry at top methods for metal cutting.

Technological Advances in Precision Cutting

Recent technological advancements have further revolutionized precision cutting methods. The integration of AI and IoT in cutting technologies has enabled enhanced precision, reduced downtime, and improved production rates. These technological breakthroughs hold promise for future manufacturing advancements.

Case Studies: Precision Cutting in Action

Case studies across various industries, from automotive to aeronautics, demonstrate the successful implementation of precision cutting methods. These real-world examples highlight the efficiency and effectiveness of different techniques in achieving optimal manufacturing results.

Challenges in Implementing Precision Cutting Methods

While the advantages are clear, implementing precision cutting methods presents challenges, including cost of equipment, technical know-how requirements, and maintenance needs. Overcoming these challenges requires strategic planning and investment in training and technology upgrades.

Future Trends in Precision Cutting

The future of precision cutting is promising. As industries continue to innovate, we can expect further developments in cutting technologies, driven by demands for higher precision, speed, and environmental sustainability. These trends will shape the evolution of industrial manufacturing.

Conclusion: Embracing Precision Cutting for Success

In conclusion, understanding and utilizing the various types of precision cutting methods is essential for industrial manufacturers seeking to remain competitive. By embracing these cutting-edge technologies, companies can enhance precision, reduce costs, and contribute to sustainable manufacturing practices.

FAQs About Precision Cutting Methods

1. What is the most accurate precision cutting method?

Laser cutting is often regarded as the most accurate method due to its ability to achieve intricate designs and clean cuts.

2. How does water jet cutting differ from plasma cutting?

Water jet cutting utilizes a high-pressure water stream, whereas plasma cutting uses an electric arc to melt the material. Each method is suitable for different material types and applications.

3. Are these precision cutting methods environmentally friendly?

Many precision cutting methods, like water jet and laser cutting, offer environmentally friendly options by reducing waste and enhancing energy efficiency.

This article contains affiliate links. We may earn a commission at no extra cost to you.