In the world of industrial manufacturing, precision is key. When you are working with small parts, applying the right cutting techniques can significantly impact the quality of the final product. Understanding and implementing these techniques will help enhance your manufacturing process, bringing about optimal results.

Manufacturers are continually presenting innovations in cutting methods to improve precision and efficiency. By mastering different cutting techniques for small parts, you can overcome common challenges and set a benchmark for quality and reliability.

The Importance of Precision in Cutting Small Parts

Precision cutting is not just about making sure the small parts fit; it’s about ensuring durability, reliability, and efficiency. Each small part needs to be cut perfectly to achieve the desired performance in the machinery or product in which it will be used. Even the smallest deviations can lead to significant errors, which is why understanding the right cutting techniques is crucial. For more details on achieving precision, visit precise metal cutting.

Common Challenges in Cutting Small Parts

One major challenge in cutting small parts is maintaining accuracy. Small parts often require intricate cuts, where even the slightest error can lead to rejections and wastage. Manufacturers need to keep an eye on common issues such as material warping, tool wear, and maintaining consistent quality for every piece produced.

Another challenge is minimizing material waste. Efficient cutting techniques aim to maximize material usage by ensuring that cuts are efficient and the leftover material is minimized.

Types of Cutting Techniques

There is a variety of cutting techniques used for handling small parts. Below, we will discuss some of the most popular ones that manufacturers use today:

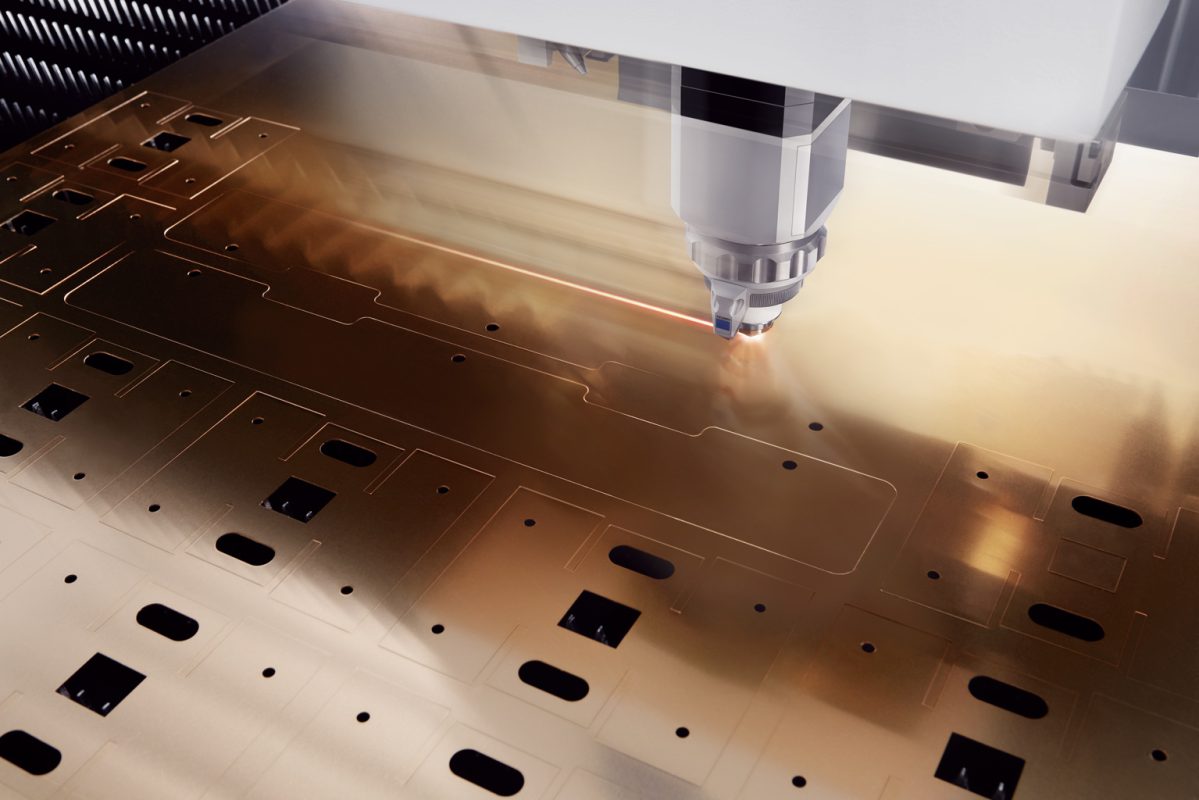

1. Laser Cutting

Laser cutting provides high precision and is often used for materials like metal and plastic. This method involves focusing a high-powered laser onto the material, which melts or vaporizes the section being cut. Laser cutting is popular for its ability to produce intricate designs with high accuracy.

2. Waterjet Cutting

Using high-pressure jets of water, waterjet cutting can slice through a wide range of materials. Since no heat is involved, it’s an excellent choice for materials sensitive to heat. For more information on this method, visit waterjet metal cutting.

3. CNC Machining

CNC machining uses computer numerical control to manage tools and enhance accuracy in cutting small parts. This method is favored for its ability to quickly switch between different designs and its application to a wide range of materials.

4. Electrical Discharge Machining (EDM)

EDM is used primarily for hard metals or those that are challenging to machine by traditional means. This technique utilizes electric arcing to erode material in highly detailed patterns.

Applications of Cutting Techniques

The efficient cutting techniques for small parts find applicability across various industriesautomotive, aerospace, and electronics manufacture small parts that need precise cuts for safety and functionality.

Best Practices for Cutting Small Parts

Consistent maintenance of equipment, regular inspections for tool wear, and proper training for machine operators are some practices that ensure efficiency while employing cutting techniques in small parts production. For insights on handling sophisticated machinery, and maintaining quality, learn more at safety tips for cutting.

Conclusion

Understanding various cutting techniques for small parts is essential for industrial manufacturers who strive for high-quality production. By investing in the right technology and focusing on precision, companies can produce superior components while reducing waste and increasing efficiency. Innovations continue to emerge, paving the way for more precise, faster, and sustainable cutting methodologies that will shape the future of manufacturing.

For more about precision sheet metal tools, check external insights at precision sheet metal techniques.

FAQ

What is the most precise cutting technique for small parts?

Laser cutting and CNC machining are typically considered among the most precise techniques due to their high degree of accuracy and control over the final output.

Why is precision so important in cutting small parts?

Precision ensures that each part fits and functions perfectly, avoiding misalignments or potential failures in the machinery or applications where these parts are utilized.

How can I reduce waste while cutting small parts?

Utilizing efficient cutting techniques, ensuring equipment is well-maintained, and regularly training staff on best practices can all contribute to reducing material waste.

This article contains affiliate links. We may earn a commission at no extra cost to you.