In the world of industrial manufacturing, efficiency and precision are crucial. One of the key players in achieving these goals is transfer press stamping equipment. Understanding how this equipment functions can greatly benefit your manufacturing processes. Let’s delve into the essential insights of this vital machinery.

What is Transfer Press Stamping Equipment?

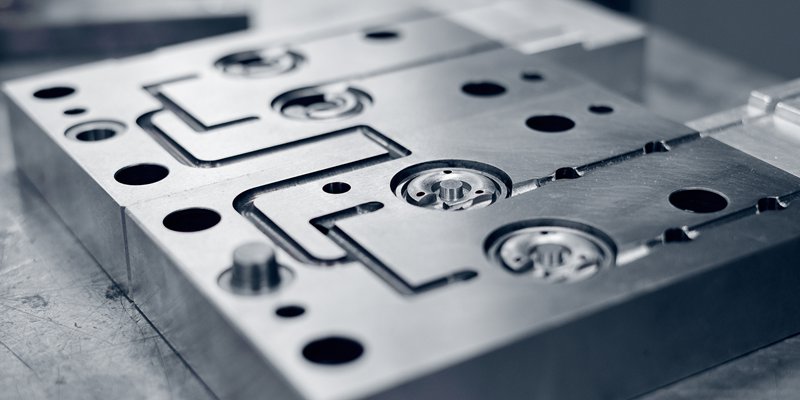

Transfer press stamping equipment is a type of machinery used in the metalworking industry to shape and form metal sheets into various components. It operates by transferring the workpiece from one station to another within the press, allowing for multiple operations in a single cycle. This method enhances production speed and reduces manual handling, which can significantly improve efficiency in manufacturing plants.

The Importance of Transfer Presses in Manufacturing

For industrial manufacturers, utilizing transfer press stamping equipment offers numerous advantages. The capability to perform several stamping operations in one machine cycle ensures a consistent and high-quality output. Moreover, it minimizes the risk of errors and wastage, thus optimizing the use of materials.

Key Features of Transfer Presses

When considering transfer press stamping equipment, there are several features to keep in mind:

- High Speed: Transfer presses are designed to operate at high speeds, which increases production capacity.

- Versatility: These machines can handle a wide range of materials and processes, making them suitable for various applications.

- Automation: Modern transfer presses often incorporate automated systems for efficient and precise operations.

Applications of Transfer Press Stamping

The applications of transfer press stamping equipment are vast and varied. From automotive components to household appliances, these machines play a pivotal role in producing high-quality, durable parts. Their ability to perform complex operations efficiently makes them a valuable asset in any manufacturing setting.

Choosing the Right Transfer Press Stamping Equipment

Selecting the right transfer press stamping equipment for your manufacturing needs involves careful consideration of several factors:

Understanding Your Production Requirements

Before investing in transfer press stamping equipment, it’s crucial to understand your specific production requirements. Consider the types of materials you work with, the volume of production, and the complexity of the parts you need to produce. This understanding will guide you in choosing equipment that meets your operational needs.

Evaluating Machine Specifications

Transfer press stamping equipment comes with various specifications, such as tonnage capacity, speed, and automation features. Evaluating these specifications in line with your production goals will ensure you select the most suitable machinery.

Supplier Reputation and Support

When purchasing transfer press stamping equipment, consider the reputation of the supplier and the support services they offer. A reliable supplier will provide quality equipment and offer after-sales support, ensuring your machinery operates efficiently over time.

Maintenance and Safety Tips

To maximize the lifespan and efficiency of transfer press stamping equipment, regular maintenance is essential. Here are some maintenance and safety tips:

Regular Inspections

Conduct regular inspections of your transfer press stamping equipment to identify any signs of wear and tear. This proactive approach will prevent unexpected breakdowns and maintain operational efficiency.

Training and Safety Protocols

Ensure that all operators are well-trained in using transfer press stamping equipment. Implement safety protocols to prevent accidents and ensure a safe working environment for your employees.

The Future of Transfer Press Stamping Equipment

As technology continues to evolve, so does the potential of transfer press stamping equipment. Manufacturers are continually innovating to improve speed, precision, and automation in these machines. Keeping abreast of these advancements will ensure your manufacturing processes remain competitive and efficient.

Embracing Technological Advancements

Incorporating the latest technology in your transfer press stamping equipment can enhance productivity and quality. From smart sensors to advanced automation, staying updated with technological trends will give you a competitive edge.

For more information on sheet metal stamping, visit this comprehensive guide.

FAQs

What are the benefits of using transfer press stamping equipment?

Transfer press stamping equipment offers high-speed production, versatility in handling various materials, and automation for efficient operations.

How do I choose the right transfer press for my needs?

Consider your production requirements, evaluate machine specifications, and research supplier reputation and support services.

What maintenance is required for transfer press stamping equipment?

Regular inspections, operator training, and adherence to safety protocols are essential for maintaining the equipment’s efficiency.

For more insights on quality metal garden art, explore our guide or learn about DIY laser cut metal art projects.

This article contains affiliate links. We may earn a commission at no extra cost to you.