In the world of industrial manufacturing, tool steel for stamping dies plays a critical role. As industries continue to evolve, understanding the significance and applications of this material is vital for manufacturers aiming for efficiency and quality in their production processes.

What is Tool Steel?

Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited for making tools. It is known for its hardness, resistance to abrasion, and ability to retain a cutting edge at high temperatures. These properties make it an ideal choice for stamping dies used in various manufacturing processes.

Types of Tool Steel for Stamping Dies

Cold Work Tool Steels

These are used for applications that require high wear resistance and toughness. They are commonly employed in electronics stamping.

Hot Work Tool Steels

These steels are designed to withstand high temperatures, making them suitable for die casting and extrusion processes.

High-Speed Tool Steels

Known for their ability to cut materials at high speeds, these are essential in industries that require precision and efficiency.

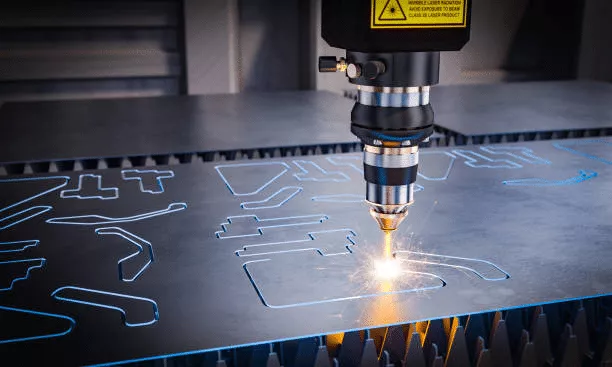

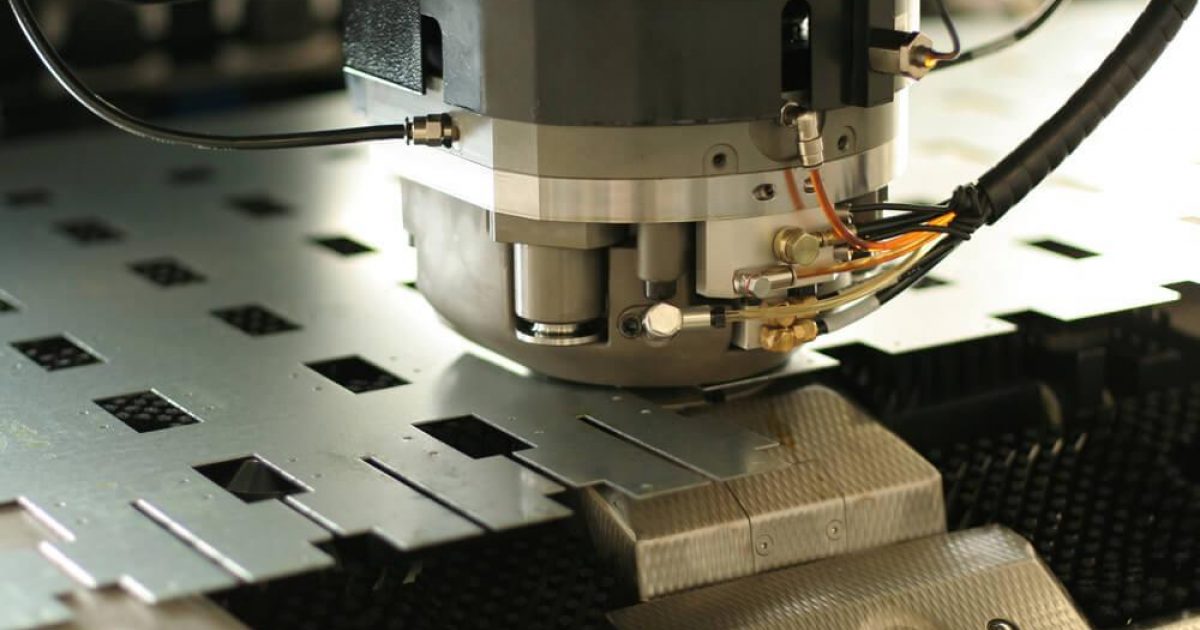

The Role of Tool Steel in Stamping Dies

Stamping dies are crucial components in the production of metal parts. They shape, cut, and form metal sheets into desired forms. The quality of the tool steel used in these dies directly impacts the quality of the final product.

Durability and Longevity

The durability of tool steel ensures that stamping dies can withstand the rigors of manufacturing without frequent replacements, which is crucial for maintaining production efficiency.

Precision and Accuracy

High-quality tool steel allows for precise and accurate stamping, which is essential for industries such as medical device manufacturing.

Choosing the Right Tool Steel

When selecting tool steel for stamping dies, manufacturers must consider factors such as the type of material being stamped, the complexity of the die, and the production volume.

Material Compatibility

The compatibility of tool steel with the material being stamped is crucial for minimizing wear and maximizing efficiency.

Cost Considerations

While high-quality tool steel might be more expensive initially, its durability and performance can lead to cost savings in the long run.

Maintenance and Care for Tool Steel Dies

Proper maintenance of stamping dies is essential to prolong their lifespan. Regular inspection and timely replacement of worn-out parts can prevent costly downtime.

Lubrication and Cleaning

Maintaining proper lubrication and cleanliness can significantly enhance the performance and lifespan of tool steel dies.

Regular Inspection

Regular checks for wear and tear can help identify potential issues before they cause significant problems.

Technological Advances in Tool Steel

Recent advancements in metallurgy have led to the development of new tool steel variants that offer improved performance and efficiency.

Innovations in Alloy Composition

Modern alloys are designed to offer better wear resistance and toughness, enhancing the capabilities of stamping dies.

Enhanced Heat Treatment Processes

Improved heat treatment techniques have resulted in tool steels with superior hardness and durability.

Conclusion

Understanding the importance and applications of tool steel for stamping dies is crucial for manufacturers. By selecting the right type of tool steel and maintaining it properly, manufacturers can ensure high-quality production and long-term cost savings.

FAQs

What is the best type of tool steel for stamping dies?

The best type depends on the specific application and material being stamped. Cold work tool steels are often used for their wear resistance and toughness.

How often should stamping dies be inspected?

Regular inspections are recommended, with frequency depending on production volume and material used.

Can tool steel be recycled?

Yes, tool steel can be recycled, making it an environmentally friendly choice for manufacturers.

This article contains affiliate links. We may earn a commission at no extra cost to you.