In the realm of industrial manufacturing, the art and science of thin metal cutting techniques hold significant importance. As manufacturing demands increase, understanding and applying these techniques become crucial for efficiency and precision. Within the first two paragraphs of this article, we will delve into what makes these techniques indispensable for today’s industrial landscape.

Understanding the Importance of Precision

Precision is a cornerstone of successful manufacturing. The ability to cut thin metal with exactness affects everything from product quality to production costs. Precise metal cutting ensures that parts fit together as intended without the need for further adjustments.

The Rise of Modern Cutting Methods

Over the years, thin metal cutting techniques have evolved significantly. Manufacturers now have access to advanced tools and methodologies that make cutting more efficient and less wasteful. For instance, the adoption of waterjet cutting has drastically improved the accuracy and speed of cutting processes.

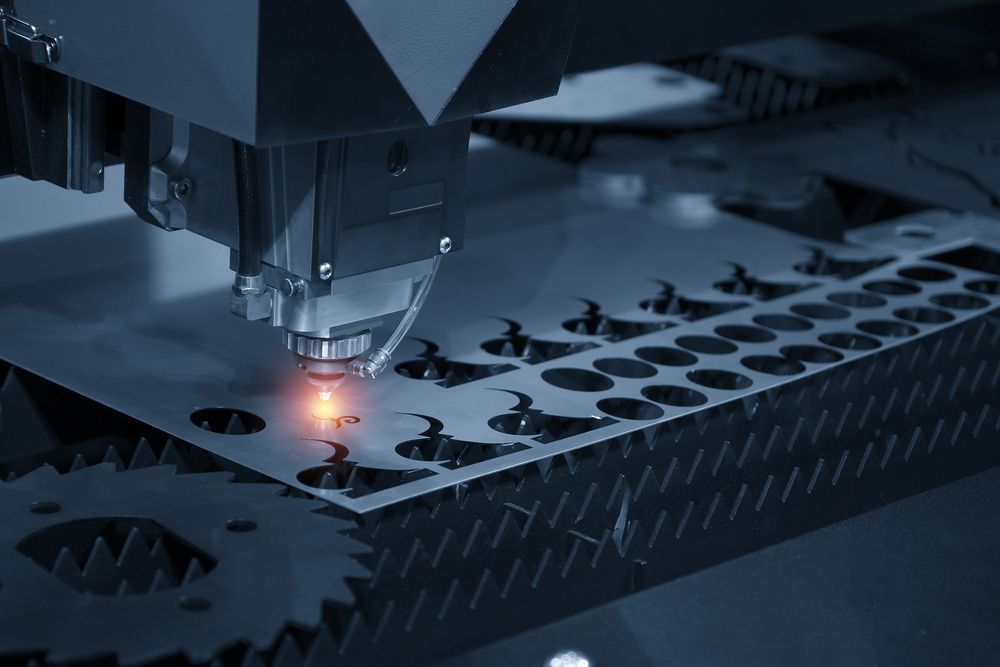

Laser Cutting

Laser cutting is a ubiquitous technology in the industry, known for its precision and versatility. This technique uses a focused laser beam to melt, burn, or vaporize material. It is ideal for cutting intricate shapes in thin metal with minimal wastage.

Waterjet Cutting

An abrasive waterjet is another effective method for cutting. It employs high-pressure water mixed with abrasive materials to erode the metal. This method leaves no heat-affected zones, preserving the integrity of the metal.

Plasma Cutting

Although plasma cutting is often associated with thicker metals, it is also efficient for thin metal. It works by sending an electrical arc through a gas, turning the gas to plasma which cuts through metal.

Benefits of Using Modern Techniques

Modern methods of metal cutting offer numerous advantages including faster production times, higher accuracy, and reduced material waste. Each method has unique strengths and is suited to different types of metal and cutting requirements.

CNC Machines

Computer Numerical Control (CNC) machines have revolutionized thin metal cutting techniques. These automated machines carry out pre-programmed sequences, ensuring consistent precision and the ability to handle complex designs efficiently.

Challenges in Thin Metal Cutting

Despite advancements, thin metal cutting is not without its challenges. Issues can arise such as metal warping due to excessive heat or inaccuracies caused by machine calibration. Understanding these challenges is essential for efficient manufacturing.

Heat Generation

One primary issue is the heat generated during the cutting process. This can lead to metal deformation, especially in cases where high temperatures are involved, such as with laser cutting.

Material Limitations

Different metals respond differently to various cutting techniques. Understanding these material properties helps manufacturers select the appropriate method for their needs.

Ensuring Quality and Accuracy

Quality controls such as checking dimensions and surface quality are imperative. Regular equipment maintenance and precise calibration of cutting tools can prevent errors and ensure quality outcomes.

Testing and Calibration

Frequent testing and calibration ensure machines are operating effectively, minimizing errors and maintaining the desired tolerances.

Future of Metal Cutting

The future for thin metal cutting techniques looks promising with continuous innovation. Emerging technologies such as AI and machine learning are set to revolutionize the landscape even further.

Automation and AI

Automation, combined with AI, is increasingly being integrated into cutting processes to enhance efficiency and reduce human error. These technologies offer predictive insights that can further streamline operations.

Conclusion

Mastering thin metal cutting techniques is pivotal in todays fast-paced industrial world. As techniques continue to evolve, staying informed about cutting-edge methods and technologies will ensure competitive advantages in manufacturing.

FAQs

What are the best tools for cutting thin metal?

Tools like laser and waterjet cutters are highly effective for thin metal due to their precision and capability to handle complex patterns.

Can traditional methods be used for thin metals?

Traditional methods can still be used, but modern techniques generally offer greater efficiency and accuracy.

What are some common challenges when cutting thin metal?

Heat generation and machine calibration are common challenges manufacturers face when dealing with thin metal.

This article contains affiliate links. We may earn a commission at no extra cost to you.