In the dynamic world of manufacturing, embracing sustainable stamping press technologies is crucial for companies aiming to reduce their environmental footprint and enhance efficiency. These technologies are not just a trend but a necessity in today’s eco-conscious era. As industries strive to meet global sustainability standards, understanding and implementing these technologies can be a game-changer.

What Are Stamping Press Technologies?

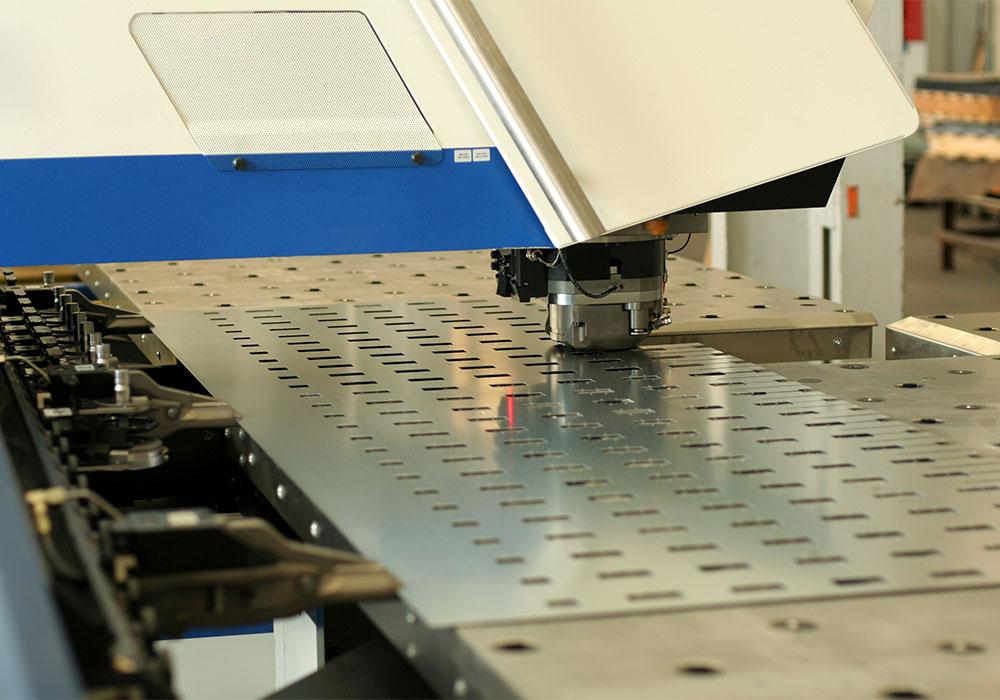

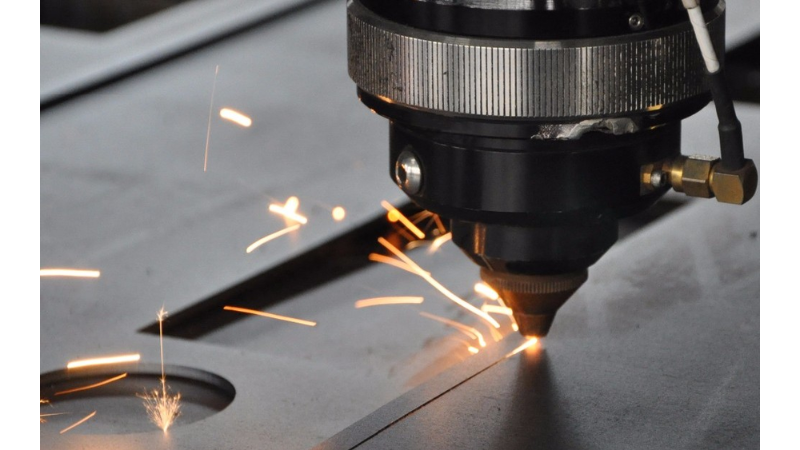

Stamping press technologies involve the use of machinery to shape or cut metal into desired forms. They are widely used in various industries, including automotive, aerospace, and electronics. The process involves applying a force using a press to transform the metal sheet into a specific shape.

Why Sustainability Matters

Sustainability in manufacturing is about minimizing waste, reducing energy consumption, and using resources more efficiently. With the growing awareness of environmental issues, industries are under pressure to adopt more sustainable practices. This shift not only helps in preserving the planet but also in improving a company’s brand image and operational efficiency.

Key Features of Sustainable Stamping Press Technologies

Energy Efficiency

Modern stamping presses are designed to consume less energy. By using advanced motors and control systems, these machines can significantly reduce electricity usage. This not only lowers the carbon footprint but also leads to cost savings.

Material Optimization

One of the primary goals of sustainable technologies is to minimize waste. By optimizing the use of materials, companies can reduce scrap and ensure that raw materials are utilized to their fullest potential.

Reduced Emissions

Advanced stamping presses are equipped with systems that reduce harmful emissions. This is achieved through better control of the manufacturing process and the use of cleaner technologies.

Implementing Sustainable Practices

Adopting sustainable stamping press technologies requires a strategic approach. Here are some steps manufacturers can take:

Conducting Energy Audits

Before implementing new technologies, it is essential to understand the current energy consumption levels. Conducting an energy audit can help identify areas where improvements can be made.

Investing in New Equipment

While the initial investment in sustainable technologies might be high, the long-term benefits often outweigh the costs. Newer machines are more efficient and can lead to significant savings in energy and materials.

Training Employees

For a smooth transition to sustainable practices, it is crucial to train employees. This not only includes operating new machines but also understanding the importance of sustainability in their daily tasks.

Case Study: Successful Implementation

Many companies have successfully implemented sustainable stamping press technologies. For instance, a leading automotive manufacturer reduced its energy consumption by 30% after upgrading its stamping presses. This not only helped in reducing costs but also in meeting environmental regulations.

Challenges and Solutions

While the benefits of sustainable technologies are clear, there are challenges in implementation. These include high initial costs, resistance to change, and the need for continuous training. However, with the right strategy and commitment, these challenges can be overcome.

Overcoming Resistance

Change is often met with resistance. To overcome this, it is essential to communicate the benefits of sustainable technologies to all stakeholders. This can be achieved through workshops, seminars, and regular updates.

Continuous Improvement

Sustainability is not a one-time effort. It requires continuous monitoring and improvement. Regularly reviewing processes and technologies can help in identifying areas for further enhancement.

Future of Sustainable Stamping Press Technologies

The future of manufacturing lies in sustainability. As technologies continue to evolve, we can expect more efficient and eco-friendly solutions. The integration of digital technologies, such as IoT and AI, will further enhance the capabilities of stamping presses, making them smarter and more sustainable.

For more insights on metal stamping, check out this comprehensive guide.

Conclusion

In conclusion, sustainable stamping press technologies are not just a trend but a necessity for modern manufacturing. By embracing these technologies, companies can not only reduce their environmental impact but also enhance their operational efficiency. The journey towards sustainability is ongoing, but with the right mindset and tools, it is achievable.

FAQs

What are the benefits of sustainable stamping press technologies?

Sustainable stamping press technologies offer several benefits, including reduced energy consumption, minimized waste, and lower emissions. These technologies help companies save costs while also meeting environmental regulations.

How can companies implement sustainable stamping technologies?

Companies can start by conducting energy audits to identify areas for improvement. Investing in new, efficient equipment and training employees are also crucial steps in implementing sustainable practices.

What challenges do companies face in adopting sustainable technologies?

Some common challenges include high initial costs, resistance to change, and the need for continuous training. However, with a strategic approach, these challenges can be overcome.

This article contains affiliate links. We may earn a commission at no extra cost to you.