In today’s rapidly evolving industrial landscape, the focus on stamping press waste reduction strategies has never been more crucial. Industrial manufacturers are continuously seeking ways to optimize their processes, reduce waste, and improve efficiency. By implementing effective waste reduction strategies in stamping press operations, manufacturers can not only reduce costs but also contribute positively to environmental sustainability.

Understanding and applying stamping press waste reduction strategies can significantly impact the overall productivity and environmental footprint of a manufacturing facility. In this article, we will explore various methods and best practices that manufacturers can adopt to minimize waste in their stamping press operations.

Why Waste Reduction is Important

The importance of waste reduction cannot be overstated. Reducing waste helps in conserving resources, lowering production costs, and minimizing environmental impact. For industrial manufacturers, these advantages translate into better market competitiveness and compliance with environmental regulations.

Identifying Sources of Waste in Stamping Press Operations

To effectively reduce waste, manufacturers must first identify the sources of waste within their stamping press operations. Common sources include material scrap, energy inefficiencies, machine downtime, and production errors.

Material Scrap

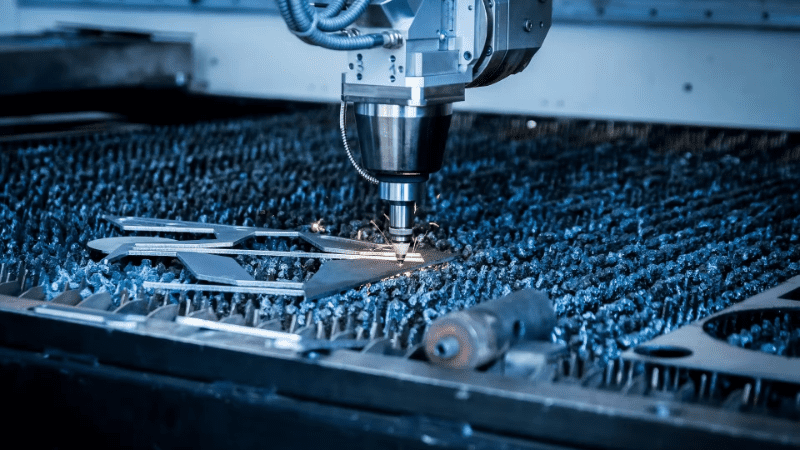

Material scrap is one of the most significant sources of waste in stamping operations. It usually results from improper cutting, excessive trimming, or defects in the metal sheets used.

Energy Inefficiencies

Energy inefficiencies occur when machinery consumes more power than necessary. This not only increases operational costs but also contributes to a larger carbon footprint.

Machine Downtime

Downtime in stamping operations can lead to significant losses. Understanding the causes of downtime and implementing strategies to minimize it is essential for efficient production.

Production Errors

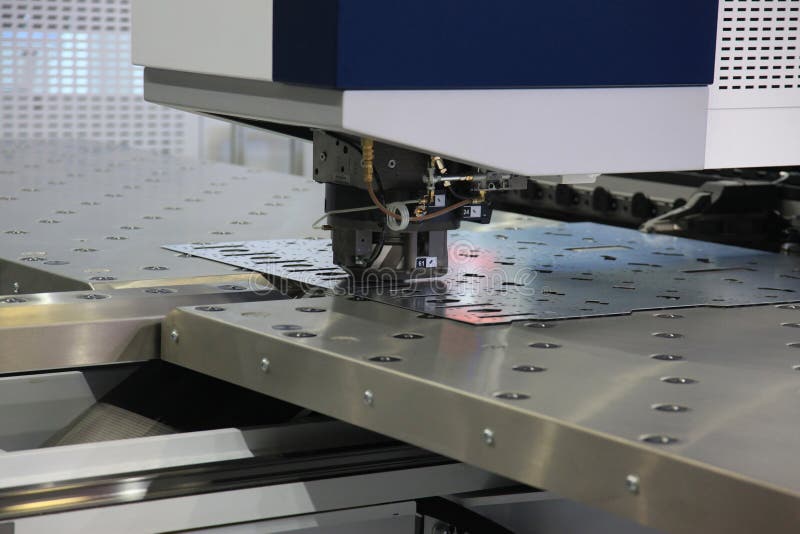

Production errors, such as misaligned parts or incorrect stamping force, can result in defective products and increased waste.

Strategies for Reducing Waste in Stamping Press Operations

Implementing stamping press waste reduction strategies involves a multi-faceted approach. Below are some proven strategies:

Lean Manufacturing Principles

Adopting lean manufacturing principles helps in identifying and eliminating waste, thus improving overall efficiency. Lean techniques focus on streamlining processes, optimizing resource use, and enhancing product quality.

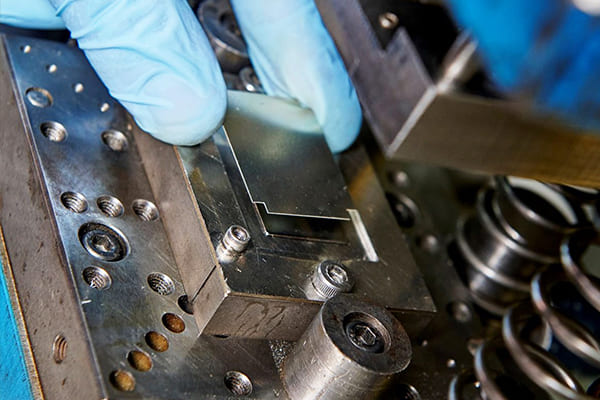

Regular Maintenance and Upgrades

Regular maintenance of stamping presses and periodic upgrades to newer, more efficient models can significantly reduce waste. This includes regular inspection, calibration, and replacement of worn-out parts.

Training and Skill Development

Investing in employee training ensures that workers are skilled in operating machinery efficiently and effectively, reducing the likelihood of errors and waste.

Advanced Monitoring Systems

Implementing advanced monitoring systems can help track performance metrics, identify inefficiencies, and enable timely interventions. For more information on monitoring systems, visit Stamping Press Monitoring.

Material Optimization Techniques

Optimizing the use of materials through better design and precise cutting can reduce scrap and improve yield. This involves using computer-aided design (CAD) software and other technological tools.

Energy Management

Implementing energy management systems can help reduce energy consumption and costs. These systems monitor energy use and provide insights into areas where improvements can be made.

Case Study: Successful Waste Reduction in Stamping Press Operations

Consider a manufacturer who implemented a comprehensive waste reduction strategy. By adopting lean manufacturing techniques, upgrading machinery, and investing in employee training, they successfully reduced waste by 30%. This not only improved their bottom line but also enhanced their reputation as a sustainable manufacturer.

Benefits of Waste Reduction in Stamping Press Operations

Waste reduction in stamping press operations offers numerous benefits, including cost savings, enhanced productivity, and a reduced environmental footprint. Additionally, manufacturers that focus on sustainability practices can improve their brand image and attract eco-conscious customers.

Challenges in Implementing Waste Reduction Strategies

Despite the benefits, implementing waste reduction strategies can present challenges. These include the initial investment cost, resistance to change from employees, and the need for continuous monitoring and improvement.

Overcoming Challenges in Waste Reduction

To overcome these challenges, manufacturers can focus on fostering a culture of continuous improvement, providing adequate training, and setting achievable goals for waste reduction.

The Future of Waste Reduction in Stamping Press Operations

The future of waste reduction in stamping press operations lies in technological advancements and increased awareness of sustainability. Innovations such as the Internet of Things (IoT), artificial intelligence, and automation are expected to play a crucial role in further enhancing waste reduction efforts.

Conclusion

In conclusion, applying stamping press waste reduction strategies is essential for industrial manufacturers aiming to improve efficiency, reduce costs, and contribute to environmental sustainability. By understanding the sources of waste and implementing targeted strategies, manufacturers can achieve significant improvements in their operations.

FAQs

What are some common sources of waste in stamping press operations?

Common sources include material scrap, energy inefficiencies, machine downtime, and production errors.

How can manufacturers reduce material scrap?

Manufacturers can reduce material scrap by optimizing material use, improving design processes, and using advanced cutting technologies.

What role does training play in waste reduction?

Training ensures that employees are skilled in operating machinery efficiently, reducing the likelihood of errors and waste.

For more insights into the **stamping press** process, you can visit Sheet Metal Stamping Process.

This article contains affiliate links. We may earn a commission at no extra cost to you.