In the realm of industrial manufacturing, the efficient operation of machinery is crucial. One of the key aspects that often goes unnoticed yet plays a vital role in maintaining machinery health is stamping press vibration analysis. This process not only ensures the smooth functioning of the machinery but also helps in reducing downtime, thereby increasing productivity. In this article, we will delve into the significance of stamping press vibration analysis and how it impacts the manufacturing process.

What is Stamping Press Vibration Analysis?

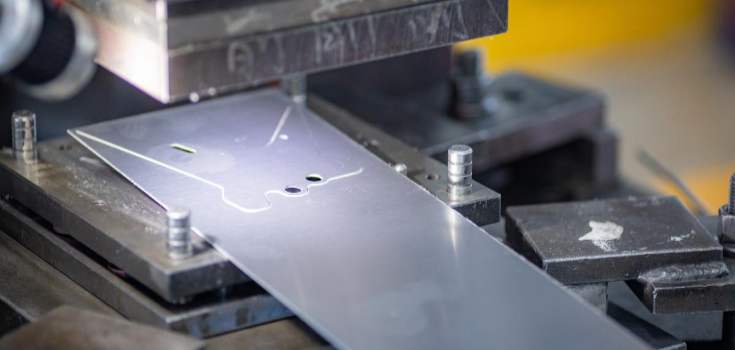

Stamping press vibration analysis involves the monitoring and analyzing of vibrations produced by a stamping press during its operation. This analysis helps identify any irregularities or potential issues within the machinery. By understanding the vibration patterns, operators can take preemptive measures to prevent major breakdowns.

The Importance in Industrial Manufacturing

In industrial settings, machinery like stamping presses are subject to continuous wear and tear. Over time, this can lead to inefficiencies and unexpected failures. By conducting regular vibration analysis, manufacturers can ensure that their equipment is operating at optimal levels. This not only maximizes the lifespan of the machinery but also enhances the quality of the products being manufactured. More insights on maintaining equipment can be found in this productivity improvement guide.

Key Components of Vibration Analysis

Vibration Sensors

These are the primary tools used in vibration analysis. They detect and measure the vibration frequency and amplitude, providing crucial data that can be analyzed for irregularities.

Data Analysis Software

Once the data is collected, specialized software is used to analyze it. This software can identify patterns and anomalies that may indicate potential issues.

Regular Monitoring

Consistent monitoring is key to effective vibration analysis. By regularly checking the vibration levels, operators can ensure that the machinery remains in good health.

Common Causes of Vibration in Stamping Presses

Several factors can contribute to vibrations in a stamping press. These include misalignment of components, wear and tear of parts, and imbalance in rotating parts. Addressing these issues promptly can prevent further complications.

Advantages of Vibration Analysis

Increased Equipment Lifespan

By identifying and addressing issues early, vibration analysis can significantly extend the lifespan of a stamping press.

Cost Savings

Preventive maintenance through vibration analysis can save manufacturers substantial amounts in repair and replacement costs.

Improved Product Quality

Consistent machinery performance ensures that the products manufactured are of high quality, meeting industry standards.

Challenges in Implementing Vibration Analysis

While the benefits of vibration analysis are clear, implementing it can present challenges. These include the initial cost of equipment, training for personnel, and integrating the process into existing workflows.

Case Study: Successful Implementation

Many companies have successfully integrated vibration analysis into their operations. For instance, a leading automotive parts manufacturer reported a 20% increase in production efficiency after implementing a comprehensive vibration analysis program. They were able to detect minor issues before they escalated, thus reducing downtime and maintenance costs. To learn more about the differences in equipment, check out this equipment comparison.

Technological Advancements in Vibration Analysis

With advancements in technology, vibration analysis has become more sophisticated. Modern sensors and software provide more accurate data and insights, making the process more efficient and reliable.

Future Trends in Stamping Press Maintenance

The future of stamping press maintenance lies in predictive analytics. By leveraging data from vibration analysis, manufacturers can predict potential failures before they occur, allowing for proactive maintenance strategies.

Conclusion

In conclusion, stamping press vibration analysis is an essential component of industrial manufacturing. By understanding and implementing this process, manufacturers can ensure the longevity and efficiency of their machinery, leading to cost savings and improved product quality. For more detailed information on the stamping process, visit Wikipedia’s stamping page.

FAQs

1. How often should vibration analysis be conducted?

It is recommended to conduct vibration analysis at least once every quarter, depending on the usage and condition of the machinery.

2. Can vibration analysis predict all types of machinery failures?

While vibration analysis is highly effective in predicting many types of failures, it may not detect issues unrelated to vibration, such as electrical faults.

3. Is it necessary to hire a professional for vibration analysis?

While companies can train in-house personnel, hiring a professional ensures that the analysis is conducted accurately and efficiently, especially in complex cases.

This article contains affiliate links. We may earn a commission at no extra cost to you.