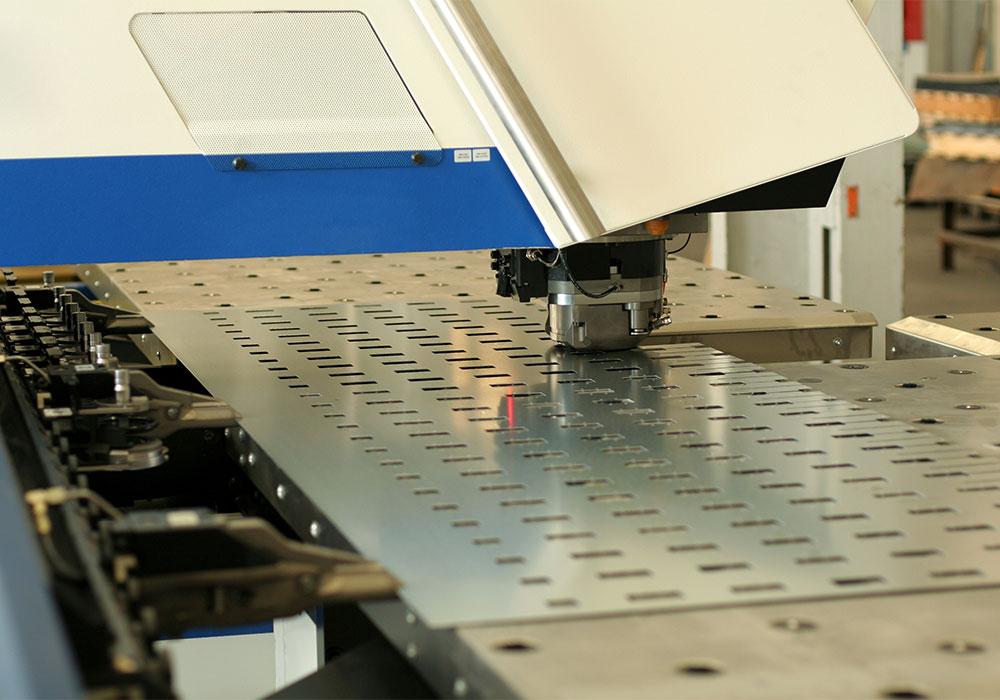

Understanding stamping press troubleshooting is essential for those in the industrial manufacturing sector. The performance and efficiency of a stamping press are crucial for maintaining production deadlines and ensuring product quality. However, like any complex machinery, a stamping press can encounter issues that may halt operations or lead to defects. This article aims to provide comprehensive insights into effectively addressing these problems.

What is Stamping Press Troubleshooting?

At its core, stamping press troubleshooting involves identifying, diagnosing, and resolving issues that arise within a stamping press machine. This process ensures that the equipment operates smoothly, reducing downtime and improving overall productivity. Whether it’s a mechanical failure, electrical issue, or quality control problem, troubleshooting is a critical skill for operators and maintenance teams.

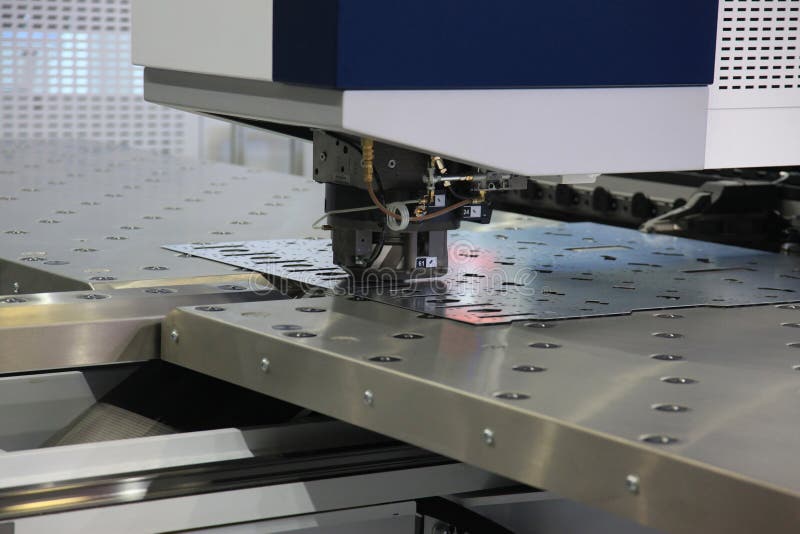

Common Problems in Stamping Presses

Mechanical Failures

Mechanical failures can range from minor malfunctions to significant breakdowns. Common issues include misalignment, wear and tear of components, and lubrication problems. Regular maintenance and inspection can help prevent these issues.

Electrical Issues

Electrical problems are another common occurrence in stamping presses. Faulty wiring, power surges, and circuit failures can disrupt operations. Ensuring proper electrical connections and having a reliable power supply can mitigate these issues.

Quality Control Concerns

Quality control problems often arise when the output of a stamping press doesnt meet the desired specifications. This can be due to incorrect settings, tool wear, or material inconsistencies. Regular quality checks and calibrations are essential for maintaining high standards.

Steps for Troubleshooting Stamping Press Issues

Initial Assessment

The first step in troubleshooting is conducting a thorough assessment of the situation. This involves gathering information about the problem, reviewing recent maintenance records, and visually inspecting the equipment.

Identifying the Root Cause

Once the initial assessment is complete, the next step is identifying the root cause of the issue. This may involve using diagnostic tools, consulting with operators, and examining the affected components.

Implementing Solutions

After identifying the root cause, it’s time to implement the appropriate solutions. This could involve repairing or replacing faulty parts, adjusting machine settings, or revising maintenance protocols.

Preventive Measures for Stamping Presses

Regular Maintenance

Regular maintenance is key to preventing issues before they arise. This includes routine inspections, lubrication, and part replacement. A well-maintained machine is less likely to experience unexpected breakdowns.

Operator Training

Ensuring that operators are well-trained in the use of stamping presses can significantly reduce the likelihood of errors. Training programs should cover both basic operation and advanced troubleshooting techniques. For more on operator training, visit operator training.

Monitoring and Reporting

Implementing a system for monitoring and reporting issues can help detect problems early. This proactive approach allows for swift action and minimizes production disruptions.

Advanced Troubleshooting Techniques

Using Diagnostic Tools

Advanced diagnostic tools can provide detailed insights into the performance of a stamping press. These tools help in pinpointing issues that may not be visible during a standard inspection.

Consulting Experts

In some cases, consulting with experts or manufacturers can provide additional support. They can offer specialized knowledge and solutions tailored to specific machines. For more information, refer to sheet metal stamping process.

Benefits of Effective Troubleshooting

Increased Efficiency

Effective troubleshooting can lead to increased efficiency by minimizing downtime and ensuring that the stamping press operates at optimal capacity.

Cost Savings

By addressing problems promptly, companies can save on costly repairs and avoid production delays. This proactive approach contributes to overall cost savings.

Improved Product Quality

Consistent troubleshooting and maintenance result in better product quality, as machines are kept in top condition, reducing the risk of defects.

Conclusion: The Importance of Stamping Press Troubleshooting

In conclusion, stamping press troubleshooting is a vital aspect of industrial manufacturing. By understanding common issues and implementing effective solutions, manufacturers can enhance productivity, reduce costs, and maintain high product quality. Continuous learning and adaptation to new technologies will further improve troubleshooting practices.

FAQs

Why is regular maintenance important for stamping presses?

Regular maintenance helps prevent unexpected breakdowns, ensuring the stamping press operates efficiently and prolongs its lifespan.

What should operators do if they encounter a problem?

Operators should immediately report the issue to the maintenance team and document any observations that may assist in troubleshooting.

How can training improve troubleshooting skills?

Training provides operators with the knowledge needed to identify and address issues quickly, reducing downtime and improving overall efficiency. For additional insights, explore quality control.

This article contains affiliate links. We may earn a commission at no extra cost to you.