In today’s fast-paced industrial world, stamping press training programs are crucial for ensuring that workers are equipped with the necessary skills to handle complex machinery with precision and efficiency. These programs are designed to provide comprehensive knowledge and hands-on experience, making them essential for anyone looking to excel in the field of precision manufacturing.

The Importance of Stamping Press Training

With the increasing demand for high-quality metal products, the role of stamping presses in manufacturing has become more significant than ever. Companies are investing in stamping press training programs to ensure their workforce is not only skilled but also safety-conscious. These programs cover everything from the basics of machine operation to advanced troubleshooting techniques.

Understanding Stamping Press Basics

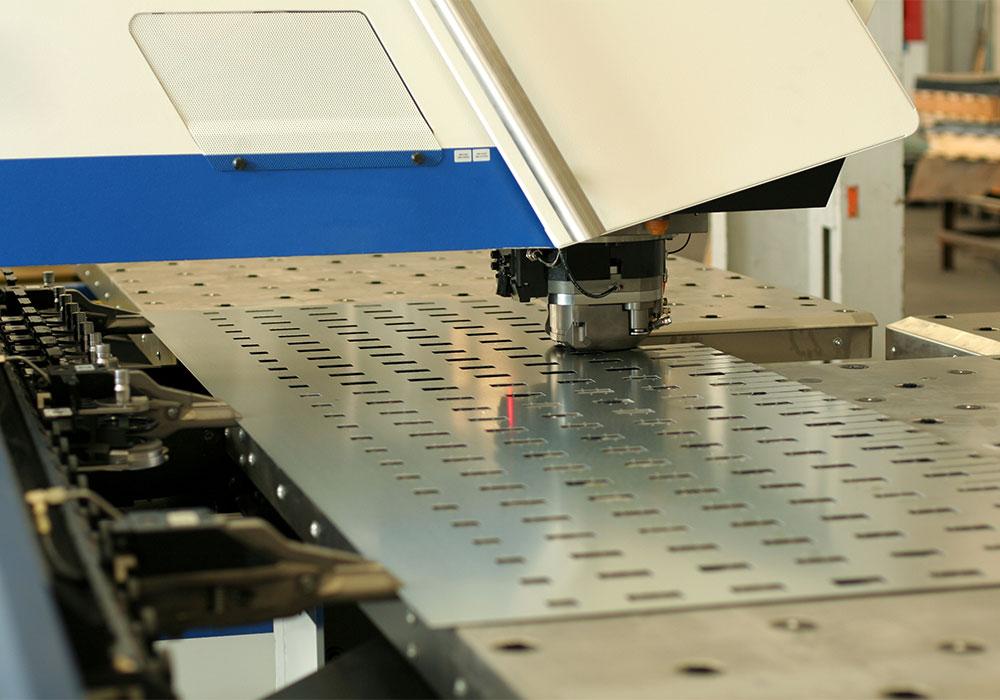

Before diving into the complexities, it’s essential to understand the basics. A stamping press is a machine used to shape or cut metal by applying pressure. It’s crucial for producing parts for various industries, including automotive, electronics, and medical devices. Familiarity with its components and functions is the first step in mastering its operation.

Components of a Stamping Press

Knowing the parts of a stamping press is fundamental. These typically include the frame, bolster plate, slide, and die cushion. Each component plays a specific role in the operation, and understanding their functions is vital for efficient usage.

How Stamping Presses Work

The operation of a stamping press involves several steps, starting from feeding the metal sheet to the final product ejection. Comprehending these steps is a part of stamping press training programs, ensuring operators can maintain a smooth production flow.

Advanced Stamping Techniques

As technology advances, so do the techniques in stamping. Modern stamping press training programs include advanced methods such as progressive die stamping and transfer die stamping. These techniques allow for the production of complex parts with higher precision.

Progressive Die Stamping

This technique involves multiple operations in a single stroke, making it efficient for high-volume production. Training in this area focuses on die design and alignment to ensure optimal performance.

Transfer Die Stamping

Unlike progressive die stamping, transfer die stamping involves moving the workpiece from one station to another. This method is ideal for larger parts, and training includes mastering the transfer systems to avoid production hiccups.

Safety in Stamping Operations

Safety is a paramount concern in any manufacturing environment. Stamping press training programs emphasize the importance of safety protocols to protect operators from potential hazards associated with machinery operation.

Essential Safety Measures

Operators must be trained in essential safety measures, such as lockout/tagout procedures, proper use of personal protective equipment, and emergency stop mechanisms. These measures are critical in preventing accidents and ensuring a safe working environment.

Ergonomic Considerations

Ergonomics also plays a vital role in stamping operations. Training programs teach operators how to maintain proper posture and handle materials to reduce physical strain and improve efficiency.

Enhancing Productivity through Training

Investing in stamping press training programs is not only about enhancing skills but also about boosting productivity. Trained operators can identify and resolve issues quickly, minimizing downtime and increasing output.

Troubleshooting and Maintenance

Effective troubleshooting and regular maintenance are integral parts of these programs. Operators learn to identify common issues, conduct routine inspections, and perform basic repairs to keep the presses running smoothly.

Lean Manufacturing Practices

Lean manufacturing practices are often incorporated into training to streamline operations. These practices focus on waste reduction, efficient resource use, and continuous improvement, all of which contribute to higher productivity.

Choosing the Right Training Program

With numerous stamping press training programs available, selecting the right one is crucial. Factors to consider include the program’s curriculum, instructor expertise, and hands-on training opportunities.

Evaluating Program Curriculum

A comprehensive curriculum should cover both theoretical knowledge and practical skills. It should include modules on machine operation, safety protocols, and troubleshooting techniques.

Instructor Expertise

The expertise of instructors is a significant factor. Experienced instructors with industry knowledge can provide valuable insights and real-world examples that enhance learning.

Hands-On Training Opportunities

Hands-on training is essential for understanding the intricacies of stamping operations. Programs that offer practical sessions allow participants to apply their knowledge and gain confidence in operating stamping presses.

Implementing Training in the Workplace

Upon completion of a training program, implementing the acquired skills in the workplace is the next step. Companies should create an environment that encourages continuous learning and supports skill application.

Creating a Learning Culture

A learning culture fosters growth and innovation. Encouraging employees to share knowledge and participate in ongoing training sessions can lead to improved performance and job satisfaction.

Monitoring and Feedback

Regular monitoring and feedback are crucial for assessing the effectiveness of training. Constructive feedback helps operators refine their skills and adapt to new challenges.

Conclusion

Stamping press training programs are vital for developing a skilled workforce capable of meeting the demands of modern manufacturing. By investing in these programs, companies can enhance productivity, ensure safety, and maintain a competitive edge in the industry.

FAQs

What are the key components of a stamping press?

The key components of a stamping press include the frame, bolster plate, slide, and die cushion. Each plays a crucial role in the machine’s operation.

Why is safety important in stamping press operations?

Safety is critical to prevent accidents and injuries. Proper training in safety protocols ensures a safe working environment and protects operators.

How does training enhance productivity in stamping operations?

Training enhances productivity by equipping operators with the skills to troubleshoot issues quickly, perform maintenance, and implement lean manufacturing practices.

For further reading on the differences between metal punching and stamping, you can visit Rapid Direct’s blog on metal punching vs. stamping.

Additionally, explore our articles on productivity improvement, consumer electronics, and used vs. new equipment to gain more insights into the stamping industry.

This article contains affiliate links. We may earn a commission at no extra cost to you.