In the world of industrial manufacturing, precision and efficiency are paramount. One of the key elements ensuring these qualities is stamping press tool alignment. Proper alignment not only enhances the quality of the products but also extends the lifespan of the tools involved.

What is Stamping Press Tool Alignment?

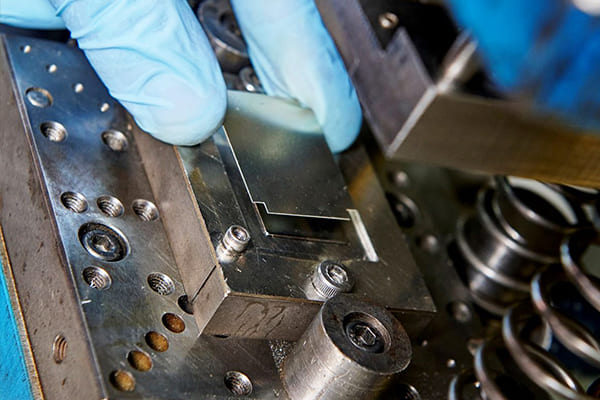

Stamping press tool alignment refers to the precise positioning of the stamping tools within the press machine. This alignment ensures that the forces during stamping are evenly distributed, reducing wear and tear on the tools and the machine. Inaccurate alignment can lead to defects in the stamped products, increased tool wear, and even damage to the press itself.

Importance of Tool Alignment in Stamping

Proper alignment is crucial for several reasons:

1. Enhanced Product Quality

When tools are correctly aligned, the stamped products meet the desired specifications and quality standards. This is essential for maintaining customer satisfaction and meeting regulatory requirements.

2. Increased Tool Life

Alignment reduces the uneven distribution of forces, thereby minimizing wear on the tools. This extends the lifespan of expensive tooling components, reducing costs over time.

3. Machine Longevity

Proper alignment prevents undue stress on the press machine, reducing maintenance needs and prolonging its operational life.

Steps in Achieving Proper Tool Alignment

Achieving perfect stamping press tool alignment involves several steps:

1. Inspection and Cleaning

Begin with a thorough inspection of the tools and the press. Clean all components to remove any debris or residues that might affect alignment.

2. Use of Alignment Tools

Utilize specialized alignment tools such as dial indicators and laser alignment systems to ensure precise positioning of the stamping tools.

3. Calibration

Regular calibration of both the press and the tools is essential to maintain alignment. This involves adjusting the equipment to meet specific alignment standards.

Challenges in Tool Alignment

Despite its importance, achieving perfect alignment can be challenging due to factors such as:

1. Tool Wear

Over time, tools wear down, which can affect alignment. Regular maintenance and replacement of worn tools are necessary.

2. Machine Variability

Machines may have inherent variabilities that affect alignment. Regular checks and adjustments are essential to compensate for these variations.

Technological Advancements in Tool Alignment

Modern technology has introduced several advancements in tool alignment, making the process easier and more accurate:

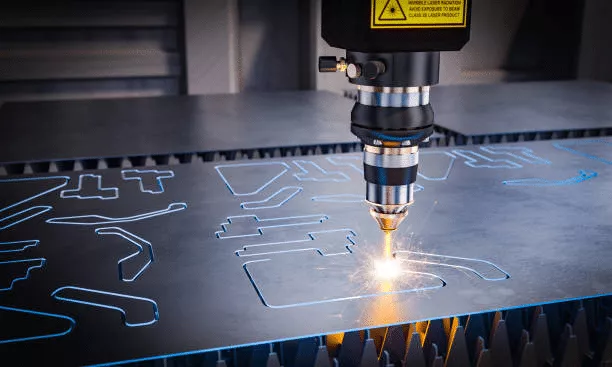

1. Laser Alignment Systems

These systems offer precise measurements and adjustments, significantly improving alignment accuracy.

2. Automated Alignment Tools

Automation in alignment tools reduces human error and enhances the precision of the alignment process.

Benefits of Proper Tool Alignment

Investing in proper tool alignment yields numerous benefits, including:

1. Cost Savings

Reduced tool wear and machine maintenance lower operational costs significantly.

2. Improved Production Efficiency

Aligned tools lead to smoother operations, reducing downtime and increasing production throughput.

3. Higher Product Quality

Consistent product quality enhances brand reputation and customer satisfaction.

Conclusion

In conclusion, stamping press tool alignment is a critical aspect of industrial manufacturing that cannot be overlooked. It ensures product quality, extends tool and machine life, and ultimately contributes to operational efficiency and cost savings. For more insights into the intricacies of metal stamping, check out this informative article. Additionally, if you’re interested in exploring creative uses of metal, take a look at some metal mosaic garden projects.

Frequently Asked Questions (FAQ)

1. How often should tool alignment be checked?

Tool alignment should be checked regularly, ideally before each production run, and whenever there is a change in tooling or machine setup.

2. What tools are used for alignment?

Common tools include dial indicators, laser alignment systems, and automated alignment devices.

3. Can poor alignment affect product quality?

Yes, poor alignment can lead to defects in the stamped products, affecting their quality and compliance with specifications.

This article contains affiliate links. We may earn a commission at no extra cost to you.