In the dynamic world of industrial manufacturing, technological advancements are pivotal for enhancing productivity and efficiency. Among these innovations, stamping press simulation software plays a crucial role in modernizing operations. This software is not just a tool but a transformative approach that enables manufacturers to optimize their processes, reduce costs, and improve product quality.

Understanding the significance of stamping press simulation software is vital for industrial manufacturers aiming to stay competitive. The software allows them to simulate and analyze stamping processes before physical implementation, thereby minimizing errors and maximizing efficiency. This article delves into the intricacies of this software, its benefits, and its impact on various industries.

What is Stamping Press Simulation Software?

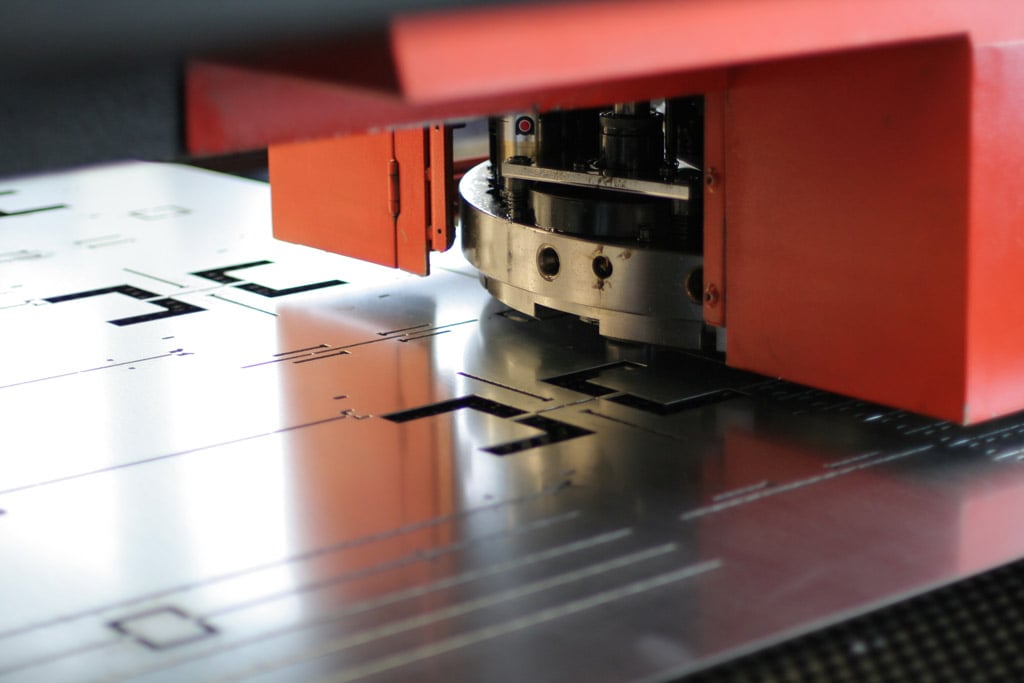

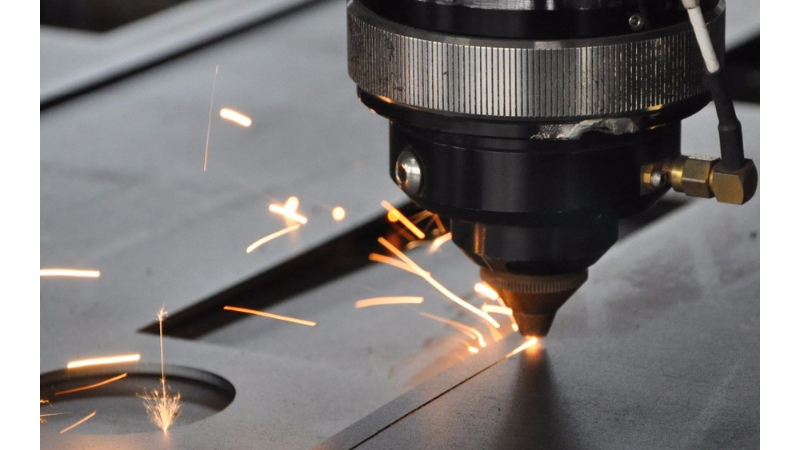

Stamping press simulation software is a digital tool used to create virtual models of stamping processes. It enables manufacturers to visualize and test the stamping operations in a virtual environment, allowing for adjustments and improvements before actual production begins. This software is particularly beneficial in designing and testing complex stamping operations, ensuring precision and reducing material waste.

Key Features of Stamping Press Simulation Software

The software offers several features that are indispensable for industrial manufacturers. These include:

- 3D Modeling: Allows for the creation of detailed three-dimensional models of stamping processes.

- Process Optimization: Helps in identifying and correcting inefficiencies in the stamping process.

- Material Analysis: Provides insights into material behavior under different conditions.

- Cost Estimation: Assists in predicting production costs and identifying cost-saving opportunities.

Why Industrial Manufacturers Need Stamping Press Simulation Software

In the competitive realm of industrial manufacturing, efficiency and precision are paramount. Stamping press simulation software caters to these needs by offering a platform to test and refine processes without incurring the costs associated with trial and error in physical production. This software is not just a cost-saving tool but a means to achieve higher quality and faster production times.

Benefits of Using Stamping Press Simulation Software

The use of stamping press simulation software offers numerous benefits that can significantly enhance industrial operations:

Improved Accuracy and Quality

By simulating stamping processes, manufacturers can identify potential issues and make necessary adjustments before commencing physical production. This leads to improved accuracy and higher quality products.

Cost Reduction

Simulation software minimizes the need for physical prototypes, thereby reducing material costs. Additionally, it helps in identifying cost-effective production methods, further contributing to cost savings.

Enhanced Efficiency

The software aids in streamlining operations by optimizing production processes. This results in faster production times and increased efficiency, which are crucial for meeting market demands.

Risk Mitigation

By allowing manufacturers to test processes in a virtual environment, the software reduces the risks associated with production, such as equipment failure and material wastage.

Customization and Flexibility

Stamping press simulation software offers customization options that enable manufacturers to tailor the software to their specific needs. This flexibility is essential for adapting to varying production requirements.

Applications of Stamping Press Simulation Software in Various Industries

The versatility of stamping press simulation software makes it applicable across a wide range of industries, including:

Automotive Industry

In the automotive sector, precision and efficiency are crucial. Simulation software helps in designing and testing components, ensuring they meet stringent industry standards.

Consumer Electronics

The consumer electronics industry benefits from the software’s ability to optimize the production of intricate components, which are essential for modern devices.

Medical Equipment Manufacturing

In the medical field, accuracy is paramount. The software aids in the production of precise components used in medical devices, ensuring they adhere to health and safety regulations.

Aerospace

The aerospace industry relies on high-quality components. Simulation software ensures that these components are manufactured to the highest standards, crucial for safety and performance.

Challenges and Future Prospects

While stamping press simulation software offers numerous benefits, it is not without challenges. These include the initial cost of software acquisition and the need for skilled personnel to operate it. However, the long-term benefits far outweigh these challenges, making it a worthwhile investment.

Future Developments

As technology continues to evolve, so will stamping press simulation software. Future developments are likely to focus on enhancing user-friendliness, integrating with other manufacturing technologies, and improving accuracy and efficiency. These advancements will further solidify the software’s role in industrial manufacturing.

Conclusion

In conclusion, stamping press simulation software is an indispensable tool for industrial manufacturers. Its ability to improve accuracy, reduce costs, and enhance efficiency makes it a valuable asset in today’s competitive market. As industries continue to evolve, the adoption of such innovative tools will be crucial for maintaining a competitive edge.

FAQs

What is the primary benefit of using stamping press simulation software?

The primary benefit is improved accuracy and efficiency in manufacturing processes, leading to cost savings and higher quality products.

How does stamping press simulation software reduce costs?

It reduces costs by minimizing material waste and the need for physical prototypes, as well as identifying cost-effective production methods.

Can stamping press simulation software be used in all industries?

Yes, it is versatile and can be applied across various industries, including automotive, consumer electronics, medical equipment, and aerospace.

For more insights on metal stamping processes, explore our other resources.

This article contains affiliate links. We may earn a commission at no extra cost to you.