The use of stamping presses is a critical aspect of manufacturing, especially within the metalworking industry. However, ensuring the safety of operators around these powerful machines is of utmost importance. Understanding and implementing effective stamping press safety tips can prevent accidents and enhance operational efficiency. This article delves into the best practices to maintain safety while operating a stamping press.

Understanding the Importance of Safety in Stamping Press Operations

Stamping presses are complex machines that require careful attention during operation. The need for safety protocols cannot be overstated. According to industry experts, a significant number of workplace injuries occur due to improper handling of machinery. Educating operators on the importance of safety is a crucial first step.

The Role of Training in Enhancing Safety

Proper training is fundamental to ensuring safety in the workplace. Operators should be thoroughly trained on how to use the equipment, understand the potential hazards, and know how to react in case of emergencies. Regular training sessions and drills can significantly reduce the risk of accidents.

Implementing Safety Guards and Devices

One of the most effective safety measures is the use of safety guards and devices. These include barriers that prevent accidental contact with moving parts of the machine. Installing such devices is a mandatory practice in many regions and ensures a safe working environment.

Regular Maintenance and Inspection

Maintaining the stamping press in good condition is crucial for safety. Regular inspections can identify potential issues before they lead to accidents. A well-maintained machine not only operates safely but also performs more efficiently. For more on maintenance, visit our die maintenance guide.

Creating a Safe Work Environment

A safe workplace is the foundation of effective safety practices. This includes having a clean and organized workspace, proper lighting, and clear signage indicating potential hazards. Ensuring that emergency exits are accessible and that safety equipment is readily available is also vital.

Personal Protective Equipment (PPE)

Personal Protective Equipment is essential for protecting operators from potential injuries. This includes gloves, goggles, ear protection, and steel-toed boots. Employers must ensure that all workers have access to and are using the appropriate PPE.

Emergency Preparedness and Response

Being prepared for emergencies can save lives. Establishing clear procedures for different types of emergencies and conducting regular emergency drills ensures that everyone knows how to respond effectively. This preparation can significantly minimize the impact of an incident.

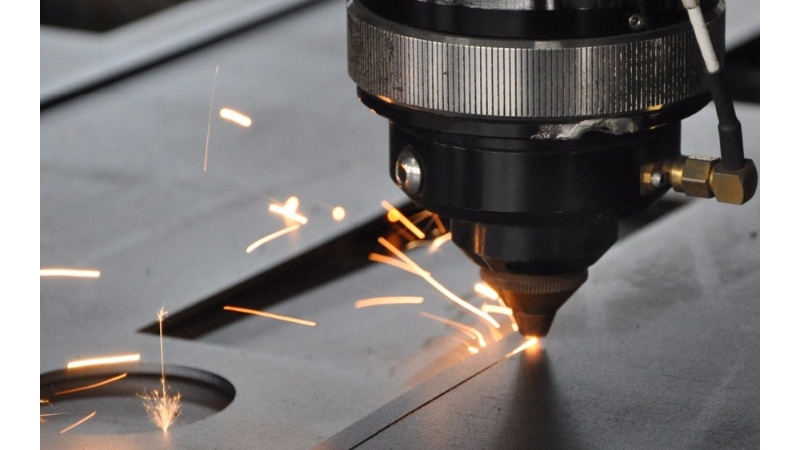

Technology and Automation in Enhancing Safety

Advancements in technology have introduced automated systems that reduce human intervention in dangerous tasks. Automation can enhance safety by performing repetitive and hazardous tasks that would otherwise pose a risk to workers.

The Future of Safety in Stamping Press Operations

As technology continues to evolve, so does the potential for improving safety in stamping press operations. Smart sensors, real-time monitoring, and predictive maintenance are just some of the innovations that promise to enhance safety and efficiency.

Quality Control and Safety

Quality control is directly linked to safety. Ensuring that each component is produced accurately reduces the risk of malfunctions and accidents. Regular inspections and adherence to quality standards are essential practices that support safe operations.

Ensuring Compliance with Safety Regulations

Compliance with safety regulations is not just a legal requirement but a moral obligation. Staying updated with the latest safety standards and implementing them in daily operations is essential for a safe workplace.

Conclusion

In conclusion, stamping press safety tips are crucial for protecting workers and ensuring efficient operations. By prioritizing safety through training, maintenance, use of protective equipment, and embracing technology, manufacturers can create a safer and more productive work environment.

FAQs

Why is training important for stamping press safety?

Training is vital because it equips operators with the knowledge to handle equipment safely, recognize hazards, and respond appropriately in emergencies.

What role does maintenance play in press safety?

Regular maintenance prevents malfunctions and ensures that the equipment operates safely and efficiently, reducing the risk of accidents.

How can technology improve safety in stamping operations?

Technology enhances safety by automating dangerous tasks, providing real-time monitoring, and enabling predictive maintenance to prevent accidents.

For further insights into metal stamping processes, you can visit Dynamic Die Supply.

This article contains affiliate links. We may earn a commission at no extra cost to you.