Recycling in industrial manufacturing is more important today than ever before. With growing environmental concerns and the need for sustainable practices, industries are focusing on innovative stamping press recycling methods to minimize waste and enhance efficiency. This article will delve into these methods, offering insights that are valuable to industrial manufacturers.

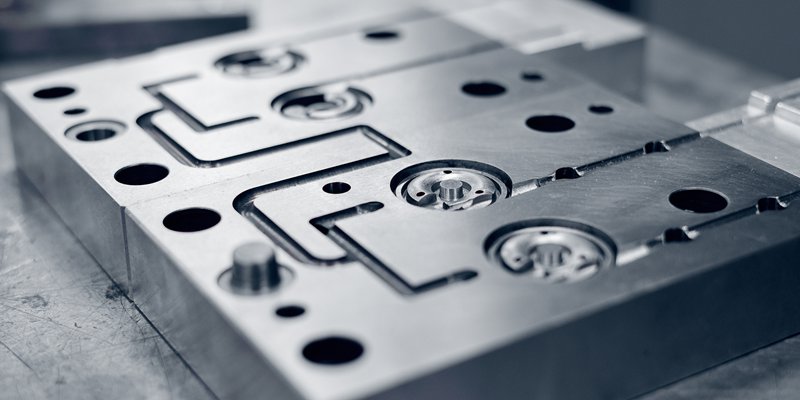

What is a Stamping Press?

A stamping press is a machine used to shape or cut metal by deforming it with a die. It’s a crucial part of the manufacturing process, particularly in the automotive, appliance, and electronics industries. While stamping presses are efficient, they generate a considerable amount of scrap metal, which needs to be recycled effectively.

Importance of Recycling in Stamping Press Operations

Recycling is essential for reducing environmental impact and conserving resources. By implementing efficient stamping press recycling methods, industries can lower production costs and reduce their carbon footprint. It also ensures compliance with environmental regulations and promotes a positive brand image.

Key Recycling Methods for Stamping Press

1. Segregation of Scrap Metal

Segregation involves sorting scrap metal into different categories based on material type and quality. This process enhances recycling efficiency by ensuring that metals are processed according to their specific properties.

2. Shredding and Melting

Shredding is a method where scrap metal is broken down into smaller pieces, making it easier to melt and repurpose. This method is particularly effective for processing large volumes of scrap metal.

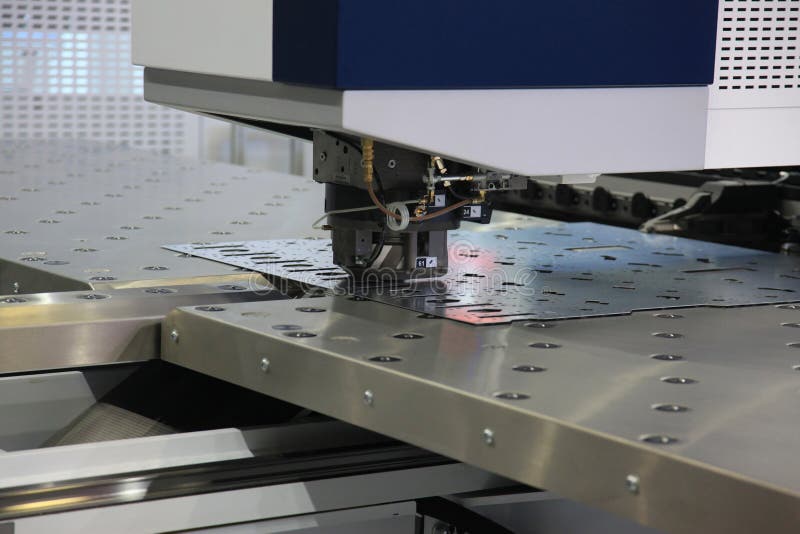

3. Automated Sorting Systems

Automated sorting systems are increasingly used in industrial settings to streamline the recycling process. These systems utilize technologies such as sensors and cameras to identify and sort different types of metals automatically.

Benefits of Recycling in Industrial Manufacturing

Recycling offers numerous benefits, including reduced production costs, lower energy consumption, and decreased landfill waste. It also enables industries to recover valuable materials that can be reused in production.

Challenges in Implementing Recycling Methods

While recycling offers significant benefits, it also presents challenges such as the need for specialized equipment and the complexity of sorting mixed materials. Additionally, some metals may require specific treatments before they can be recycled.

Innovations in Stamping Press Recycling

Recent innovations have led to the development of advanced recycling technologies such as AI-driven sorting systems and energy-efficient melting furnaces. These innovations are helping industries to improve their recycling processes and reduce their environmental impact.

Best Practices for Recycling in Stamping Operations

Implementing best practices such as regular maintenance of recycling equipment and employee training can significantly enhance recycling efficiency. Industries should also establish partnerships with specialized recycling companies to optimize their processes.

Environmental Impact of Stamping Press Recycling

Recycling not only reduces waste but also conserves natural resources and lowers greenhouse gas emissions. By adopting sustainable practices, industries can contribute to a healthier planet.

Case Studies: Successful Recycling Implementations

Several companies have successfully implemented recycling programs, achieving significant reductions in waste and production costs. These case studies provide valuable insights into effective recycling strategies and their benefits.

Future Trends in Stamping Press Recycling

The future of recycling in stamping press operations looks promising, with advancements in technology and an increased focus on sustainability. Industries are expected to adopt more automated and efficient recycling methods in the coming years.

Conclusion: The Path to Sustainable Manufacturing

Incorporating effective stamping press recycling methods is crucial for achieving sustainable manufacturing. By reducing waste and conserving resources, industries can enhance their operational efficiency and contribute to a healthier environment.

FAQ Section

What are the main benefits of recycling in stamping operations?

Recycling reduces production costs, conserves resources, and lowers environmental impact by decreasing landfill waste and greenhouse gas emissions.

How can industries improve their recycling processes?

Industries can improve recycling by implementing automated sorting systems, training employees, and partnering with specialized recycling companies.

What are the challenges of recycling in stamping press operations?

Challenges include the need for specialized equipment, sorting mixed materials, and ensuring metals receive appropriate treatments for recycling.

Learn more about metal stampingProductivity ImprovementVibration AnalysisReducing DowntimeMonitoring SystemsElectronics Metal Stamping

This article contains affiliate links. We may earn a commission at no extra cost to you.