The world of manufacturing is ever-evolving, and the need for stamping press productivity improvement has never been more crucial. As industrial manufacturers strive to enhance efficiency and output, understanding how to optimize stamping operations becomes paramount. In this article, we delve into various strategies and techniques to ensure your stamping press operations are running at their peak performance.

Understanding the Basics of Stamping Press Productivity

Before diving into advanced strategies, it’s essential to grasp the fundamental concepts of stamping press productivity. This involves recognizing the key components that contribute to efficient operations, such as machine maintenance, operator training, and process optimization.

The Role of Modern Technology

Incorporating modern technology is a game-changer for stamping press productivity. Automation, real-time monitoring, and advanced software solutions can significantly reduce downtime and improve accuracy. For more insights on modern stamping technologies, visit What is Metal Stamping?.

Key Factors Influencing Productivity

Efficient Machine Maintenance

Regular maintenance is crucial for preventing unexpected breakdowns and prolonging the lifespan of your equipment. Implementing a proactive maintenance schedule can minimize disruptions and enhance overall productivity.

Operator Training and Skill Enhancement

Well-trained operators are the backbone of any productive stamping operation. Investing in ongoing training programs ensures that your team is equipped with the latest skills and knowledge. Explore more on operator training at operator training.

Quality Control and Assurance

Implementing stringent quality control measures is vital for maintaining product consistency and minimizing waste. Discover effective quality control practices by visiting quality control.

Advanced Strategies for Improvement

Lean Manufacturing Principles

Adopting lean manufacturing principles can streamline processes, reduce waste, and improve efficiency. This approach focuses on continuous improvement and eliminating non-value-added activities.

Utilizing Data Analytics

Data analytics is a powerful tool for identifying bottlenecks and optimizing operations. By analyzing production data, manufacturers can make informed decisions to enhance productivity.

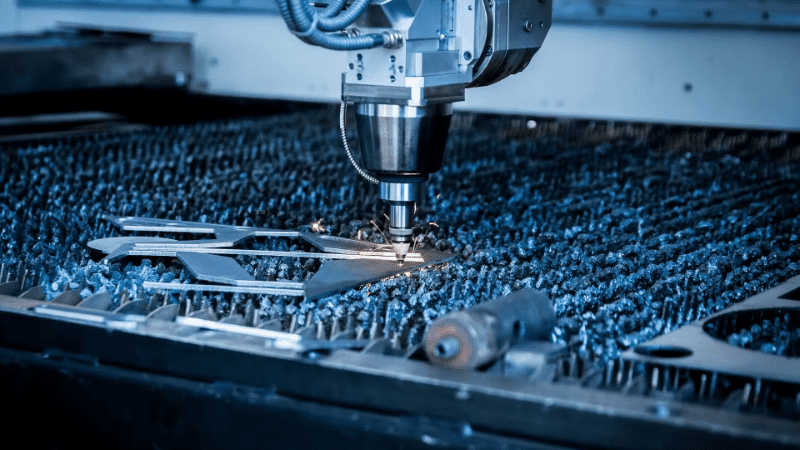

Embracing Automation and Robotics

Automation and robotics can significantly boost productivity by handling repetitive tasks with precision and speed. This allows human operators to focus on more complex responsibilities.

Choosing the Right Equipment

New vs. Used Stamping Equipment

Deciding between new and used equipment can impact productivity and cost-efficiency. For a detailed comparison, visit new vs. used equipment.

Customization and Upgrades

Customizing and upgrading equipment to meet specific production needs can enhance efficiency and output. This may involve retrofitting existing machines with modern components or investing in specialized equipment.

Overcoming Common Challenges

Addressing Downtime

Unplanned downtime is a significant barrier to productivity. Implementing predictive maintenance and quick-changeover techniques can reduce downtime and improve overall efficiency.

Managing Workforce Dynamics

Effective workforce management involves maintaining a balance between experienced and new workers. This ensures knowledge transfer and continuity in operations.

Adapting to Market Changes

Staying agile and responsive to market changes is essential for sustaining productivity. This requires a flexible production system capable of adapting to shifts in demand.

Future Trends in Stamping Press Productivity

Integration of IoT and AI

The integration of IoT and AI technologies is set to revolutionize stamping press productivity. These advancements enable predictive maintenance, real-time monitoring, and enhanced decision-making capabilities.

Sustainability and Eco-Friendly Practices

Emphasizing sustainability and eco-friendly practices is becoming increasingly important. This involves reducing energy consumption, minimizing waste, and adopting green technologies.

Conclusion

Enhancing stamping press productivity requires a multifaceted approach that combines technology, training, and strategic planning. By implementing the strategies discussed in this article, industrial manufacturers can achieve significant improvements in efficiency and output.

FAQs

What is the most effective way to improve stamping press productivity?

Integrating modern technology, such as automation and data analytics, along with regular maintenance and operator training, is highly effective in improving productivity.

How does operator training impact productivity?

Operator training enhances skill levels, reduces errors, and increases efficiency, leading to improved productivity in stamping operations.

What role does quality control play in productivity?

Quality control ensures consistency, reduces waste, and maintains product standards, all of which contribute to enhanced productivity.

This article contains affiliate links. We may earn a commission at no extra cost to you.