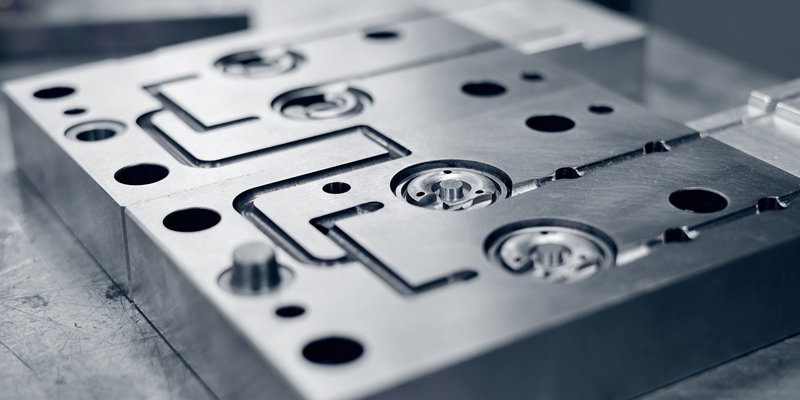

In the world of industrial manufacturing, ensuring the efficiency and quality of machinery is paramount. One such crucial element is the stamping press, a machine used to cut and form materials into specific shapes. At the heart of maximizing the potential of this equipment lies the practice of stamping press performance testing. This process is essential not only for maintaining productivity but also for ensuring safety and quality in the output.

For manufacturers, understanding the nuances of stamping press performance testing can lead to significant improvements in operations. Whether youre involved in stamping press productivity or focused on precision for consumer electronics metal stamping, this testing helps in identifying potential issues before they lead to costly downtimes or defects.

Understanding Stamping Press Performance

A stamping press functions through a combination of mechanical, hydraulic, and pneumatic systems, each playing a critical role in the overall performance. The testing of these components is crucial for maintaining the operational integrity of the machine. The focus is on assessing the machine’s ability to handle specified loads, maintain precision, and operate within safe limits.

Components of Performance Testing

The performance testing of a stamping press involves several key components:

- Load Testing: Evaluates the press’s ability to handle the maximum load without failure.

- Precision Testing: Ensures that the press can produce parts with accurate dimensions consistently.

- Cycle Time Testing: Measures the time taken for a complete press cycle, affecting overall productivity.

Benefits of Thorough Testing

Engaging in comprehensive performance testing has numerous benefits for manufacturers:

- Increased Efficiency: By identifying bottlenecks and inefficiencies, testing helps streamline operations.

- Enhanced Quality: Consistent testing ensures parts meet quality standards, reducing waste.

- Cost Savings: Preventive testing can identify potential failures before they happen, saving on repair costs.

Link to Quality Control

Performance testing is closely linked to quality control in stamping production. By integrating testing results into quality control processes, manufacturers can ensure that all outputs meet the desired specifications, leading to higher customer satisfaction and fewer returns.

Testing Techniques

Various techniques are employed to test different aspects of a stamping press, ensuring comprehensive coverage.

Non-destructive Testing (NDT)

Non-destructive testing methods, such as ultrasonic and radiographic testing, are used to inspect the integrity of the press without causing any damage. These methods help in identifying internal defects that could affect performance.

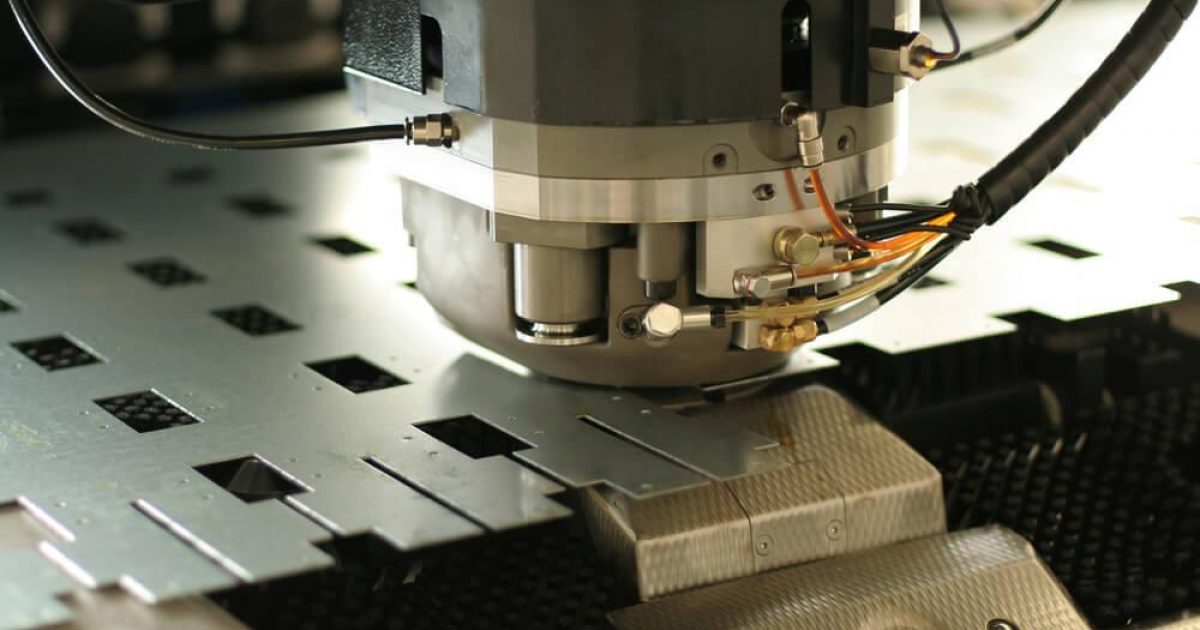

Operational Testing

This involves running the press under normal operational conditions to monitor its performance. It helps in identifying issues that only arise during actual use, such as overheating or abnormal vibrations.

Challenges in Performance Testing

While stamping press performance testing offers numerous benefits, it also presents certain challenges:

- Complexity: The intricate nature of modern presses requires advanced testing techniques and skilled operators.

- Time Consumption: Thorough testing can be time-consuming, potentially affecting production schedules.

- Cost: The investment in testing equipment and personnel can be significant, though it often pays off in the long term.

Innovations in Testing

Technology is continuously evolving, bringing new innovations to the field of performance testing.

Automation and AI

Automation and AI are increasingly being integrated into testing processes to enhance accuracy and efficiency. These technologies allow for real-time monitoring and predictive maintenance, reducing the likelihood of unexpected downtimes.

IoT Integration

The Internet of Things (IoT) is playing a crucial role in modern performance testing. By connecting stamping presses to the internet, data can be collected and analyzed continuously, providing valuable insights into the machines health and performance.

Conclusion

Stamping press performance testing is a vital component of industrial manufacturing, contributing significantly to both efficiency and quality. By embracing comprehensive testing practices, manufacturers can not only enhance their productivity but also ensure the safety and reliability of their operations. As technology advances, so too will the methods and effectiveness of these tests, paving the way for a more efficient and innovative future in manufacturing.

FAQs

Why is stamping press performance testing important?

It ensures the machinery operates efficiently, safely, and within quality standards, preventing costly downtimes and defects.

What are the common techniques used in testing?

Common techniques include non-destructive testing, operational testing, and the integration of automation and AI for enhanced precision.

How does performance testing impact quality control?

Performance testing provides critical data that informs quality control processes, ensuring all outputs meet the desired specifications and standards.

For more detailed insights into metalworking and stamping processes, you can visit Wikipedia’s page on Stamping.

This article contains affiliate links. We may earn a commission at no extra cost to you.