In the diverse world of industrial manufacturing, the role of a stamping press operator is crucial. These operators are responsible for managing and maintaining stamping presses, which are essential in shaping and forming metal parts. This article delves into the various responsibilities of a stamping press operator, highlighting their key duties and the skills required to excel in this role.

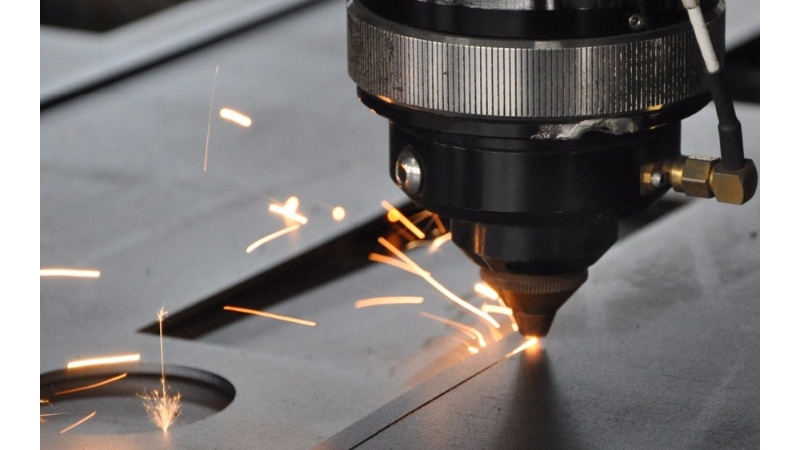

What is a Stamping Press?

A stamping press is a machine used to shape or cut metal by deforming it with a die. These machines are vital in manufacturing industries, producing parts for automobiles, appliances, and other consumer goods. Understanding how these machines work is fundamental to appreciating the responsibilities of an operator.

For more insights into how these machines function, you can visit this guide on sheet metal stamping.

Core Responsibilities of a Stamping Press Operator

1. Machine Setup and Preparation

Operators are responsible for setting up the stamping press before beginning any production run. This includes choosing the appropriate dies and configuring the machine settings according to the specifications outlined for the product.

2. Operating the Stamping Press

The primary duty of a stamping press operator is to run the machine during production. This involves monitoring the press to ensure it is functioning correctly and making adjustments as needed to maintain quality.

3. Quality Control

Conducting quality control checks is another critical responsibility. Operators must inspect the workpieces for defects, ensuring that each piece meets the required standards. For more on maintaining quality in stamping production, explore this quality control guide.

Skills Required for a Stamping Press Operator

4. Technical Proficiency

Operators must have a solid understanding of mechanical systems and be adept with the technical aspects of machinery operation. This knowledge is vital for troubleshooting and maintenance.

5. Attention to Detail

Given the precision required in metal stamping, operators must possess a keen eye for detail. This skill ensures that each part is produced to exact specifications without flaws.

6. Problem-Solving Skills

Operators often encounter issues that need quick resolutions to avoid production delays. Effective problem-solving skills are essential in diagnosing issues and implementing solutions swiftly.

Safety Responsibilities

7. Adhering to Safety Protocols

Safety is paramount in manufacturing environments. Operators must strictly follow safety protocols to protect themselves and their colleagues from potential hazards.

8. Regular Maintenance Checks

Performing regular maintenance checks is crucial to ensure the machine operates smoothly and safely. This includes checking for wear and tear and replacing parts as necessary.

Learning and Development

9. Continuous Learning

The field of manufacturing is always evolving, and operators need to stay updated with the latest technologies and processes. Engaging in continuous learning helps in keeping skills sharp and relevant.

10. Training and Certification

Obtaining certification can enhance an operator’s credibility and open up further career opportunities. Many employers offer training programs to help operators hone their skills.

Impact on Production Efficiency

11. Improving Productivity

Operators play a significant role in boosting production efficiency. By ensuring machines are running optimally, they help in minimizing downtime and maximizing output. For tips on enhancing productivity, check out this productivity improvement article.

12. Reducing Waste

Efficient operations lead to reduced waste. By ensuring that each part is manufactured correctly, operators help in minimizing material wastage, which is crucial for cost-saving and environmental considerations.

Future of Stamping Press Operators

13. Technological Advancements

As technology advances, the role of stamping press operators is continually evolving. Automation and improved machine interfaces are changing how operators interact with machinery.

14. Career Progression

Experienced operators have opportunities to advance into supervisory or managerial roles, overseeing teams and production lines. This progression is often supported by additional training and certification.

15. Industry Trends

Staying informed about industry trends is crucial. Operators who keep pace with changes in technology and market demands are better positioned to adapt and thrive in their careers.

Conclusion

The responsibilities of a stamping press operator are diverse and integral to the manufacturing process. From machine setup and operation to quality control and safety, these professionals ensure the efficient production of high-quality parts. With ongoing training and a commitment to excellence, stamping press operators are well-equipped to meet the challenges of the industry and contribute significantly to their organizations.

FAQs

What qualifications are needed to become a stamping press operator?

Generally, a high school diploma or equivalent is required, along with on-the-job training. Some employers may prefer candidates with technical certifications.

How can operators improve their skills?

Operators can improve their skills through continuous learning, attending workshops, and obtaining certifications relevant to metal stamping and machinery operation.

What are the career prospects for stamping press operators?

With experience, operators can advance to supervisory roles, become trainers, or specialize in different types of machinery, enhancing their career prospects within the manufacturing industry.

This article contains affiliate links. We may earn a commission at no extra cost to you.