In today’s competitive industrial landscape, achieving optimal efficiency is crucial for the success and sustainability of manufacturing operations. One of the key areas where efficiency can be significantly enhanced is in stamping press operations. Stamping press OEE improvement is not just a buzzword; it is a pathway to increasing productivity, reducing costs, and maintaining high-quality standards. In this article, we will delve into various strategies and insights to enhance Overall Equipment Effectiveness (OEE) in stamping press operations.

Understanding OEE in Stamping Press Operations

Before diving into improvement strategies, it is essential to understand what OEE is and why it matters. OEE is a metric that evaluates the efficiency and effectiveness of a manufacturing process. It considers three main factors: availability, performance, and quality. In the context of stamping presses, OEE measures how effectively a press is utilized compared to its full potential.

Components of OEE

OEE is comprised of three critical components:

- Availability: This measures the actual operating time of the press compared to the scheduled operating time. Downtime due to maintenance, setup changes, or unexpected breakdowns impacts availability.

- Performance: This assesses whether the press is running at its maximum speed. Any slowdowns or stoppages reduce performance.

- Quality: This evaluates the production of good parts versus defective ones. High-quality output is crucial for maintaining a high OEE score.

Key Strategies for Stamping Press OEE Improvement

Improving OEE in stamping press operations requires a comprehensive approach that addresses each component. Here are some effective strategies:

1. Implement Predictive Maintenance

Predictive maintenance involves using sensors and data analytics to forecast when a machine is likely to fail. By addressing potential issues before they lead to downtime, predictive maintenance significantly enhances availability. Many manufacturers find that this approach reduces unexpected breakdowns and extends the lifespan of the equipment.

2. Optimize Setup Times

Reducing setup times is crucial for improving availability and performance. Techniques such as SMED (Single-Minute Exchange of Die) can streamline the setup process, allowing for quicker transitions between production runs. This strategy not only increases uptime but also enhances flexibility in production scheduling.

3. Enhance Operator Training

Well-trained operators can significantly impact all three OEE components. Regular training sessions ensure operators are proficient in handling the equipment, conducting quick setups, and identifying quality issues. Empowering operators with the skills and knowledge they need can lead to noticeable improvements in overall efficiency.

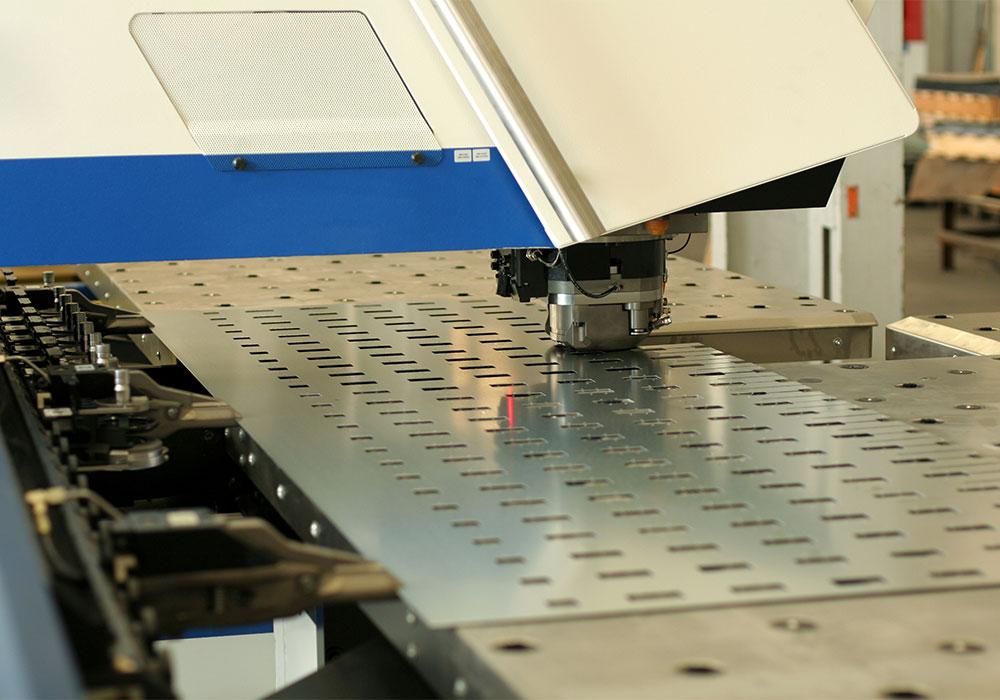

4. Use Real-Time Monitoring Systems

Real-time monitoring systems provide valuable insights into the performance of stamping presses. By tracking key metrics and identifying trends, these systems enable operators and managers to make data-driven decisions that enhance performance and quality. This proactive approach helps in addressing issues as they arise, rather than after they have impacted production.

Incorporating Technology for Better OEE

Incorporating advanced technology is a game-changer for enhancing OEE in stamping press operations. Here are some technological innovations that can lead to significant improvements:

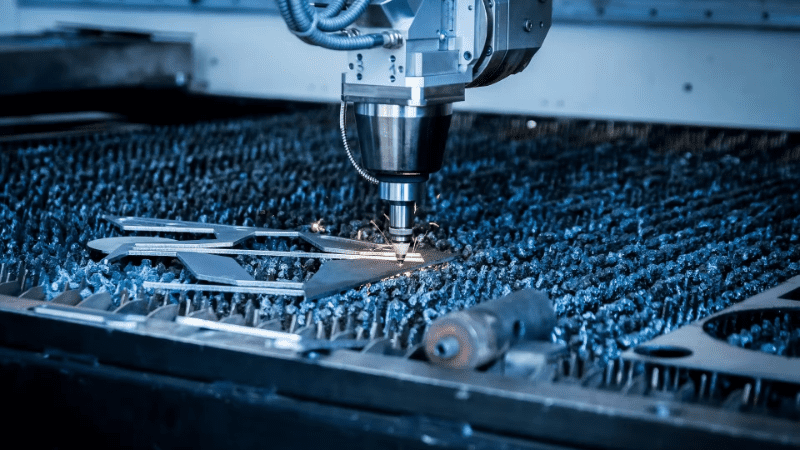

1. Automation and Robotics

Automation and robotics can dramatically improve performance by increasing speed and consistency. Automated systems reduce the risk of human error, ensure uniformity in production, and allow for faster cycle times. This advancement can be particularly beneficial for high-volume production environments.

2. Data Analytics and AI

Data analytics and artificial intelligence (AI) provide powerful tools for understanding complex manufacturing processes. By analyzing vast amounts of data, AI can identify patterns and recommend optimizations that humans might miss. Implementing AI-driven solutions can lead to continuous improvements in OEE.

Challenges in Stamping Press OEE Improvement

While the benefits of improving OEE are clear, there are challenges that manufacturers must navigate:

1. Initial Costs

Investing in new technologies, training programs, and maintenance systems requires upfront costs. However, the long-term benefits often outweigh these initial expenses, leading to a higher return on investment.

2. Resistance to Change

Change can be difficult to implement in any organization. Employees may resist new processes or technologies. To overcome this challenge, it is important to foster a culture of continuous improvement and communicate the benefits of OEE enhancements clearly to all stakeholders.

Case Studies: Successful OEE Improvements

Many companies have successfully improved their stamping press OEE by implementing the strategies discussed. For example, a leading automotive parts manufacturer achieved a 20% increase in availability by adopting predictive maintenance. Another company reduced defective parts by 15% through enhanced operator training and real-time monitoring.

Conclusion

Stamping press OEE improvement is a vital aspect of modern manufacturing. By focusing on availability, performance, and quality, manufacturers can enhance their productivity and competitiveness. Whether through advanced technology or better training, every step towards improving OEE contributes to a more efficient and profitable operation. For more insights into stamping press productivity, visit Stamping Press Productivity.

FAQs

1. What is OEE in stamping press operations?

OEE, or Overall Equipment Effectiveness, is a measure of how well a manufacturing operation is utilized compared to its full potential. It considers availability, performance, and quality to provide a comprehensive view of efficiency.

2. How can predictive maintenance improve OEE?

Predictive maintenance uses data analytics to predict when equipment is likely to fail, allowing for proactive maintenance. This reduces unexpected downtime and enhances the availability component of OEE.

3. Why is operator training important for OEE?

Operator training ensures that staff are skilled in handling equipment and identifying issues quickly. Well-trained operators can improve setup times, maintain high-quality standards, and respond effectively to any disruptions in production.

For further reading on the topic of stamping, you can visit the Wikipedia page on Stamping.

This article contains affiliate links. We may earn a commission at no extra cost to you.