In the bustling world of industrial manufacturing, the clatter and clamor of machinery are often accepted as part of the environment. However, the excessive noise generated by stamping presses can pose significant challenges. Understanding and implementing stamping press noise reduction can enhance the workplace environment, improving both safety and productivity.

Understanding the Impact of Noise in Industrial Settings

Noise in industrial environments is more than just an annoyance; it can affect worker health and operational efficiency. Prolonged exposure to high noise levels can lead to hearing loss and increased stress levels among workers. Moreover, it can disrupt communication and diminish concentration, directly impacting productivity.

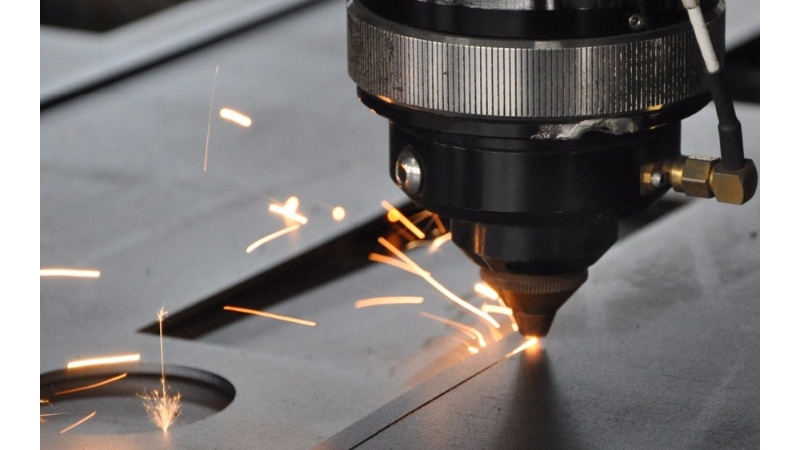

What Causes Stamping Press Noise?

The primary sources of noise in stamping presses include the mechanical actions of the press, such as the impact of the die on the material, the movement of the slide, and the operation of ancillary equipment. Each component contributes to the overall noise level, which can reach hazardous levels if not properly managed.

The Role of Die Impact

The collision between the die and the workpiece is often the loudest part of the process. This impact noise can be minimized through proper die maintenance and using materials that absorb sound.

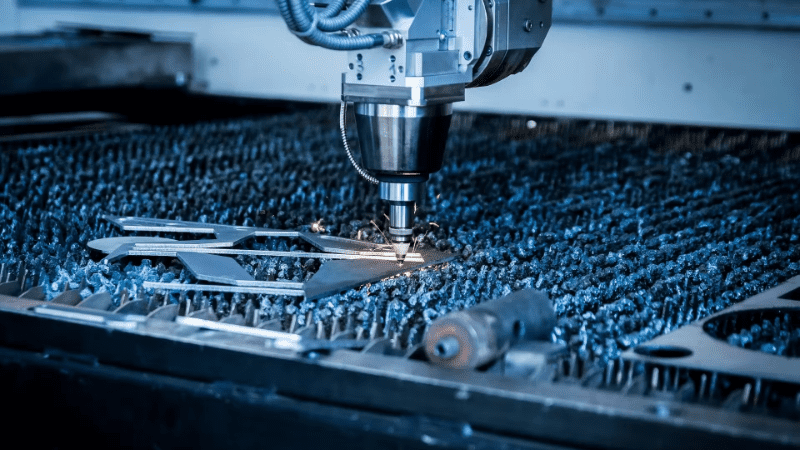

Slide Movement and Its Contribution

The movement of the slide generates noise due to friction and vibration. Regular lubrication and maintenance of the press can reduce these sounds significantly.

Strategies for Stamping Press Noise Reduction

Employing effective strategies can help in significantly reducing noise levels. These include the following:

Use of Sound Dampening Materials

Sound dampening materials, such as rubber mats and acoustic panels, can absorb excessive noise. These materials can be strategically placed around the stamping press to reduce noise transmission.

Regular Maintenance and Inspection

Routine maintenance is crucial for keeping machinery in optimal condition. Regular inspections can help identify components that may need repair or replacement, reducing noise caused by wear and tear.

Implementation of Enclosures

Enclosures can effectively contain noise within a specific area. This is particularly useful in large facilities where multiple machines operate simultaneously. Enclosures must be designed to allow for adequate ventilation to prevent overheating.

Technological Innovations in Noise Reduction

Advancements in technology offer new solutions for reducing noise in industrial settings. Innovations such as active noise control systems and quieter machinery designs are paving the way for quieter manufacturing environments.

Active Noise Control Systems

These systems use sound waves to cancel out noise. By generating a sound wave with the same amplitude but opposite phase to the noise, they effectively reduce the perceived noise level.

Quieter Machinery Designs

Modern machinery designs focus on reducing noise at the source. This includes using materials that naturally dampen sound and designing components that operate more quietly.

The Benefits of Noise Reduction in the Workplace

Reducing noise in the workplace has numerous benefits. It can lead to improved worker health, increased productivity, and compliance with safety regulations. A quieter environment can also enhance communication and reduce stress, contributing to a more pleasant workplace.

Improved Worker Health

Lower noise levels reduce the risk of hearing loss and stress-related health issues among workers. This can lead to lower absenteeism and increased job satisfaction.

Increased Productivity

A quieter environment allows workers to focus better, leading to enhanced productivity and efficiency. Clear communication is easier in a less noisy environment, reducing the chances of errors.

Compliance with Safety Regulations

Meeting noise regulations is crucial for avoiding legal issues and ensuring worker safety. Implementing noise reduction measures helps companies comply with these regulations.

Conclusion

Implementing stamping press noise reduction strategies is essential for creating a safer and more productive workplace. By understanding the sources of noise and employing effective reduction techniques, manufacturers can enhance their operational efficiency and worker well-being. As technology continues to advance, new innovations will further aid in achieving these goals.

FAQs

Q: What is the main source of noise in stamping presses?

A: The main source of noise is the impact between the die and the workpiece, along with the movement of the slide.

Q: How can noise reduction improve productivity?

A: By reducing noise levels, workers can focus better and communicate more effectively, leading to increased productivity.

Q: Are there technological solutions for noise reduction?

A: Yes, technological innovations such as active noise control systems and quieter machinery designs are available to reduce noise.

For more insights on metalworking and innovative solutions, visit here. Explore creative uses of metal in art and industry at Garden Art Ideas and Metal Mosaic Projects.

This article contains affiliate links. We may earn a commission at no extra cost to you.