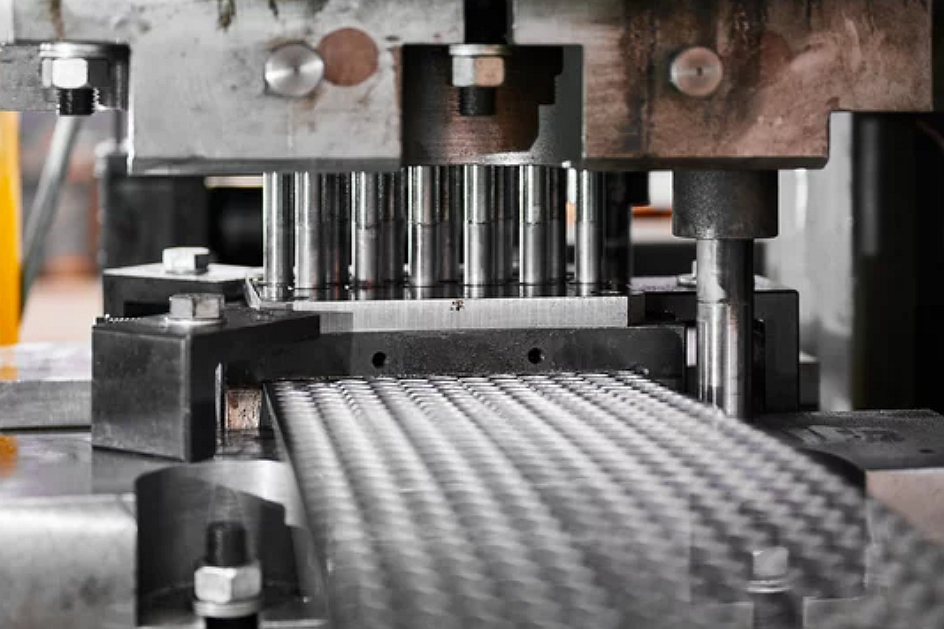

In the fast-paced world of industrial manufacturing, efficiency and precision are key. One technological advancement that has gained significant traction is stamping press monitoring systems. These systems are transforming the way industries operate by providing real-time data and insights, ensuring optimal performance and safety.

Understanding Stamping Press Monitoring Systems

Stamping press monitoring systems are sophisticated tools designed to track and analyze the performance of stamping presses. These systems use a combination of sensors, software, and data analytics to monitor various parameters of the stamping process. This includes force, speed, and temperature, among others, to ensure that the machines are operating efficiently and safely.

The Importance of Monitoring Systems in Manufacturing

For industrial manufacturers, the implementation of stamping press monitoring systems is crucial. These systems not only enhance productivity but also contribute to cost savings by reducing machine downtime and preventing potential malfunctions. With real-time data, manufacturers can make informed decisions, optimize operations, and improve overall product quality.

Key Features of Stamping Press Monitoring Systems

Some of the key features of stamping press monitoring systems include:

- Real-time data collection and analysis

- Automated alerts for anomalies

- Integration with existing manufacturing systems

- Comprehensive reporting tools

These features allow manufacturers to have better control over their operations, leading to increased efficiency and reduced costs.

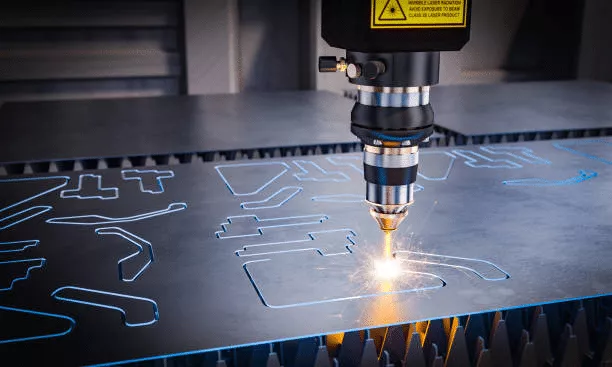

How Monitoring Systems Enhance Safety

Safety is a paramount concern in any manufacturing environment. Stamping press monitoring systems play a vital role in enhancing safety by providing timely alerts for any irregularities in the stamping process. This allows operators to take corrective actions promptly, reducing the risk of accidents and ensuring a safer workplace.

The Role of Data in Monitoring Systems

Data is at the heart of stamping press monitoring systems. The systems collect a vast amount of data, which is then analyzed to provide valuable insights into the performance of the machines. This data-driven approach helps manufacturers identify trends, predict maintenance needs, and improve operational efficiency.

Integrating Monitoring Systems with Existing Technology

One of the advantages of modern stamping press monitoring systems is their ability to integrate seamlessly with existing manufacturing technologies. This integration ensures that manufacturers can leverage their current investments while benefiting from the advanced capabilities of the monitoring systems.

Case Study: Improved Efficiency in Manufacturing

A leading automotive manufacturer implemented stamping press monitoring systems across its production lines. As a result, the company saw a significant reduction in machine downtime and an increase in production efficiency by 15%. This case study highlights the tangible benefits that these systems can bring to industrial operations.

The Future of Stamping Press Monitoring Systems

As technology continues to evolve, so too will stamping press monitoring systems. Future advancements are expected to include enhanced predictive analytics, artificial intelligence integration, and even more robust safety features. These developments will further cement the role of monitoring systems in revolutionizing industrial manufacturing.

Choosing the Right Monitoring System

When selecting a stamping press monitoring system, manufacturers should consider factors such as the system’s compatibility with existing equipment, ease of use, and the level of data analysis provided. By choosing the right system, manufacturers can maximize their return on investment and drive operational excellence.

FAQs

- What are stamping press monitoring systems? – These are tools designed to track, analyze, and optimize the performance of stamping presses in manufacturing environments.

- How do monitoring systems enhance safety? – They provide real-time alerts for irregularities, allowing for quick corrective actions to prevent accidents.

- Can monitoring systems integrate with existing technologies? – Yes, modern systems are designed to integrate seamlessly with current manufacturing technologies.

For more information on how productivity improvement can be achieved through monitoring systems, visit our detailed guide.

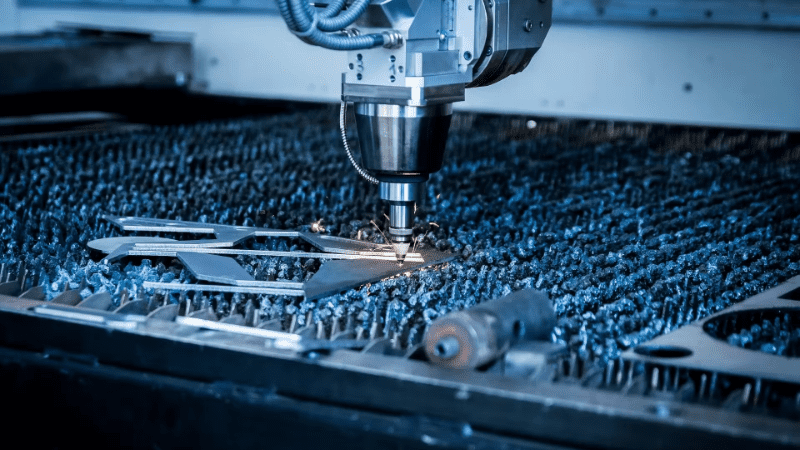

Learn more about the sheet metal stamping process to understand how monitoring systems fit into the broader manufacturing landscape.

This article contains affiliate links. We may earn a commission at no extra cost to you.