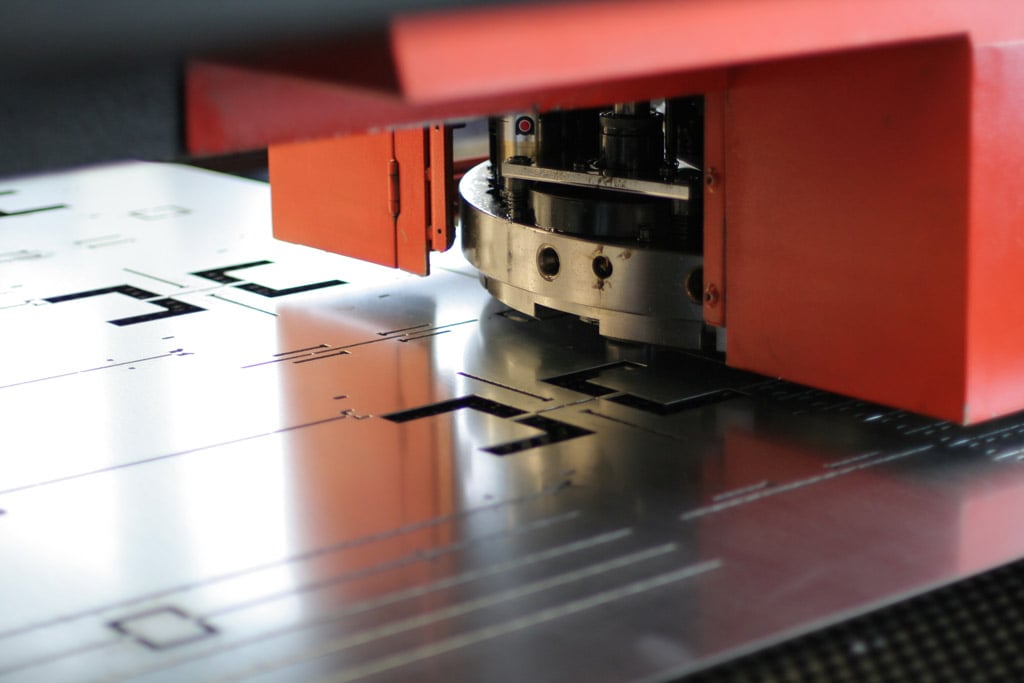

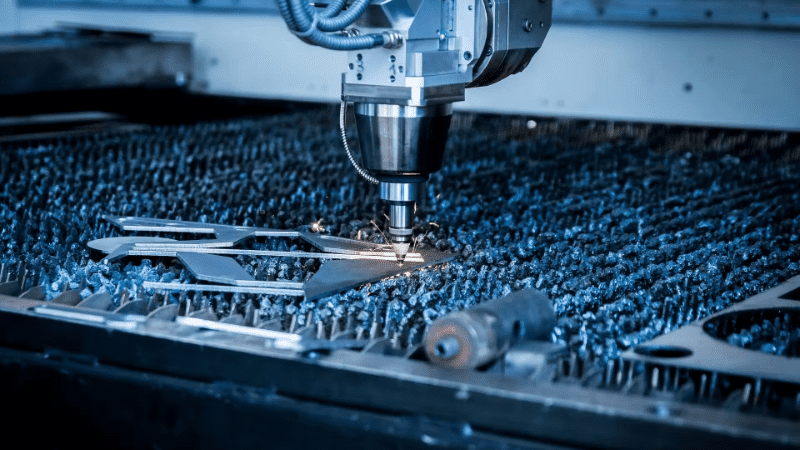

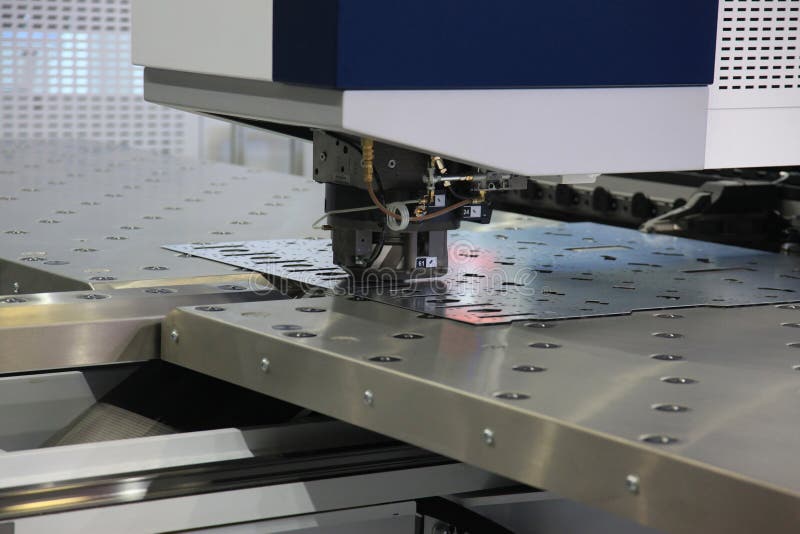

Proper maintenance of a stamping press is crucial for industrial manufacturers to ensure smooth operations and prevent unexpected downtimes. A well-structured stamping press maintenance checklist helps in maintaining the efficiency and longevity of the equipment. This comprehensive guide will walk you through the essential steps and considerations for keeping your stamping press in top shape.

Understanding the Importance of Regular Maintenance

Regular maintenance is vital in preventing costly repairs and ensuring the safety of the workplace. By adhering to a consistent maintenance schedule, manufacturers can significantly reduce the risk of equipment failure and enhance productivity. Additionally, regular inspections help identify potential issues before they escalate into major problems.

Creating an Effective Stamping Press Maintenance Checklist

1. Daily Inspection Tasks

Daily maintenance tasks are essential for identifying minor issues that could escalate if left unchecked. These tasks include:

- Checking for any signs of wear and tear on the press components.

- Ensuring all safety guards and mechanisms are functioning correctly.

- Verifying that the press is clean and free from debris.

2. Weekly Maintenance Activities

Weekly maintenance tasks focus on slightly more in-depth inspections. These include:

- Lubricating moving parts to minimize friction and wear.

- Inspecting electrical connections for signs of damage or wear.

- Checking the hydraulic system for leaks or pressure anomalies.

3. Monthly Maintenance Checks

Monthly checks are comprehensive inspections that ensure all components are functioning optimally. These include:

- Inspecting belts and pulleys for alignment and tension.

- Examining the control panel for any error messages or malfunctions.

- Reviewing the press’s performance metrics to identify any anomalies.

4. Annual Overhaul and Inspection

An annual inspection is essential for maintaining the long-term health of the stamping press. This involves:

- Conducting a thorough inspection of all components and systems.

- Replacing any worn-out parts or components.

- Updating software and control systems to the latest versions.

Key Components to Inspect in a Stamping Press

Hydraulic System

The hydraulic system is the heart of a stamping press. Regularly checking for leaks, pressure inconsistencies, and fluid levels is crucial for maintaining optimal performance.

Electrical System

Inspecting the electrical system for faulty connections, damaged wires, and malfunctioning components is vital to ensure safe and efficient operations.

Mechanical Components

Mechanical components, including gears, belts, and pulleys, must be regularly inspected for signs of wear and tear. Proper lubrication and alignment are key to preventing breakdowns.

Ensuring Safety During Maintenance

Safety should always be a top priority during maintenance activities. Ensure all personnel are adequately trained and equipped with the necessary protective gear. Follow the manufacturer’s guidelines and lockout/tagout procedures to prevent accidental startup during maintenance.

Implementing a Maintenance Schedule

Developing and adhering to a maintenance schedule is essential for maximizing the lifespan of your stamping press. Utilize software tools or apps to track maintenance activities and set reminders for upcoming tasks.

Training and Skill Development

Regular training sessions and skill development programs for operators and maintenance personnel are crucial for keeping up with the latest techniques and technologies in stamping press maintenance.

Explore our operator training resources for more information.

Leveraging Technology for Maintenance

Incorporate modern technology, such as predictive maintenance tools and IoT sensors, to monitor the health of your stamping press in real-time. This can help in predicting potential failures and planning maintenance activities accurately.

Common Mistakes to Avoid

Avoid common pitfalls such as neglecting routine inspections, ignoring warning signs, and using improper tools or techniques during maintenance activities.

Conclusion

A well-maintained stamping press ensures optimal performance, reduces downtime, and enhances workplace safety. By following this detailed stamping press maintenance checklist, industrial manufacturers can maximize the lifespan and efficiency of their equipment.

FAQs

What is the recommended frequency for stamping press maintenance?

It is recommended to perform daily, weekly, monthly, and annual maintenance checks. A detailed schedule can be customized based on the specific needs of your equipment.

How can I ensure the safety of my personnel during maintenance?

Ensure all personnel are trained and equipped with protective gear. Follow lockout/tagout procedures and manufacturer’s guidelines to prevent accidental startup.

What are some common signs of wear and tear in a stamping press?

Common signs include unusual noises, vibrations, leaks in the hydraulic system, and inconsistent performance metrics.

For more detailed insights, check out this guide on sheet metal stamping.

This article contains affiliate links. We may earn a commission at no extra cost to you.