In the realm of industrial manufacturing, the role of stamping press lubrication systems cannot be understated. These systems are pivotal in ensuring the smooth operation of stamping presses, which are integral components in the production of metal parts. By maintaining optimal lubrication, these systems enhance the efficiency and longevity of machinery, ultimately contributing to a more reliable manufacturing process.

Understanding Stamping Press Lubrication Systems

Stamping press lubrication systems are designed to deliver precise amounts of lubricant to various components of the stamping press. This is crucial in reducing friction, preventing wear and tear, and minimizing the risk of overheating. The importance of these systems is reflected in their ability to extend the lifespan of machinery and enhance production quality.

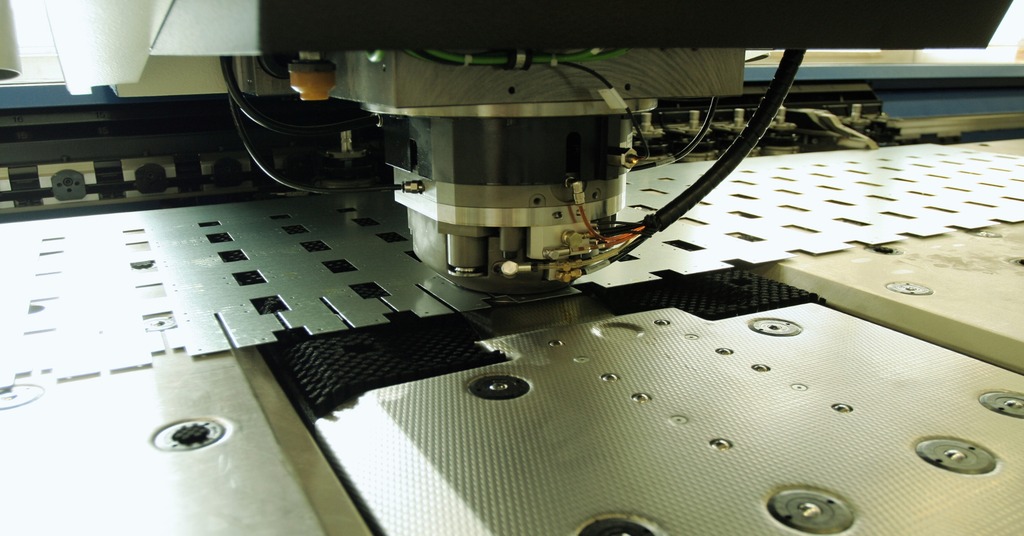

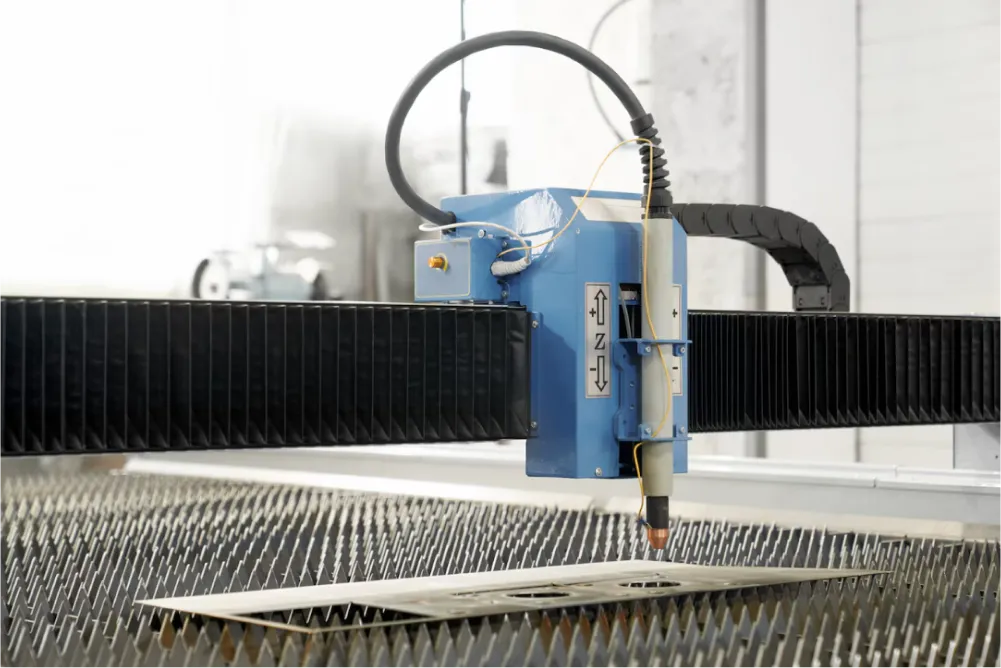

Components of a Lubrication System

A typical stamping press lubrication system includes pumps, filters, reservoirs, and distribution networks. Each component plays a vital role in ensuring that the lubricant is delivered efficiently and effectively to the necessary parts of the machine. The pumps are responsible for moving the lubricant through the system, while filters ensure that the lubricant remains free of contaminants. Reservoirs store the lubricant, and distribution networks deliver it to the necessary components.

Why Lubrication is Crucial for Stamping Presses

The primary purpose of lubrication in stamping presses is to minimize friction between moving parts. This not only reduces wear and tear but also prevents overheating, which can lead to equipment failure. Additionally, proper lubrication helps in maintaining the quality of the metal parts being produced, ensuring that they meet the necessary specifications and standards.

Impact on Machinery Longevity

By reducing friction and wear, lubrication systems play a crucial role in extending the lifespan of stamping presses. This is particularly important in industrial settings where machinery is subject to constant use and high demand. Regular maintenance and proper lubrication can prevent costly breakdowns and downtime, thus improving overall operational efficiency.

Types of Lubricants Used in Stamping Presses

There are various types of lubricants used in stamping press lubrication systems, each designed to meet specific requirements. Common types include mineral oils, synthetic oils, and greases. The choice of lubricant depends on factors such as the type of material being stamped, the operating temperature, and the speed of the stamping process.

Choosing the Right Lubricant

Selecting the appropriate lubricant for a stamping press is essential in ensuring optimal performance. Factors to consider include the viscosity of the lubricant, its thermal stability, and its ability to provide adequate protection against wear and corrosion. Consulting with experts and conducting regular assessments can help in making informed decisions about lubricant selection.

Challenges in Stamping Press Lubrication

Despite their importance, stamping press lubrication systems can face several challenges. These include contamination of lubricants, improper application, and inadequate maintenance. Addressing these challenges requires a proactive approach, including regular inspections, timely replacement of lubricants, and the use of high-quality materials.

Preventing Contamination

Contamination is a significant concern in lubrication systems, as it can lead to reduced performance and increased wear. To prevent contamination, it is essential to use clean and sealed storage containers for lubricants, regularly replace filters, and ensure that all system components are properly maintained.

Advancements in Lubrication Technology

Recent advancements in lubrication technology have led to the development of more efficient and environmentally friendly solutions. These include biodegradable lubricants, advanced filtration systems, and automated lubrication systems that ensure precise application and reduce human error. Embracing these innovations can significantly enhance the performance and reliability of stamping presses.

Automated Lubrication Systems

Automated lubrication systems are becoming increasingly popular in the manufacturing industry. These systems use sensors and control units to monitor the condition of machinery and apply lubricant as needed. This ensures consistent lubrication, reduces the risk of human error, and enhances operational efficiency.

The Future of Stamping Press Lubrication

As the manufacturing industry continues to evolve, the demand for more efficient and sustainable lubrication solutions will grow. Future trends may include the integration of IoT technology in lubrication systems, enabling real-time monitoring and data analysis to optimize performance. Additionally, the development of eco-friendly lubricants will become increasingly important as industries strive to reduce their environmental impact.

Integrating IoT in Lubrication Systems

The integration of IoT technology in lubrication systems offers numerous benefits, including real-time monitoring, predictive maintenance, and data-driven decision-making. By leveraging IoT, manufacturers can enhance the efficiency and reliability of their stamping presses, ultimately improving productivity and reducing costs.

Conclusion

In conclusion, stamping press lubrication systems are essential for maintaining the efficiency and longevity of machinery in the manufacturing industry. By understanding the components, challenges, and advancements in lubrication technology, manufacturers can make informed decisions to enhance operational efficiency and reduce costs. To learn more about the differences between metal punching and stamping, visit the RapidDirect blog.

FAQs

What is the primary function of a stamping press lubrication system?

The primary function of a stamping press lubrication system is to deliver precise amounts of lubricant to various components of the stamping press, reducing friction, preventing wear and tear, and minimizing the risk of overheating.

How can I prevent contamination in lubrication systems?

To prevent contamination in lubrication systems, use clean and sealed storage containers for lubricants, regularly replace filters, and ensure that all system components are properly maintained.

What are the benefits of automated lubrication systems?

Automated lubrication systems offer benefits such as consistent lubrication, reduced risk of human error, and enhanced operational efficiency. These systems use sensors and control units to monitor the condition of machinery and apply lubricant as needed.

This article contains affiliate links. We may earn a commission at no extra cost to you.