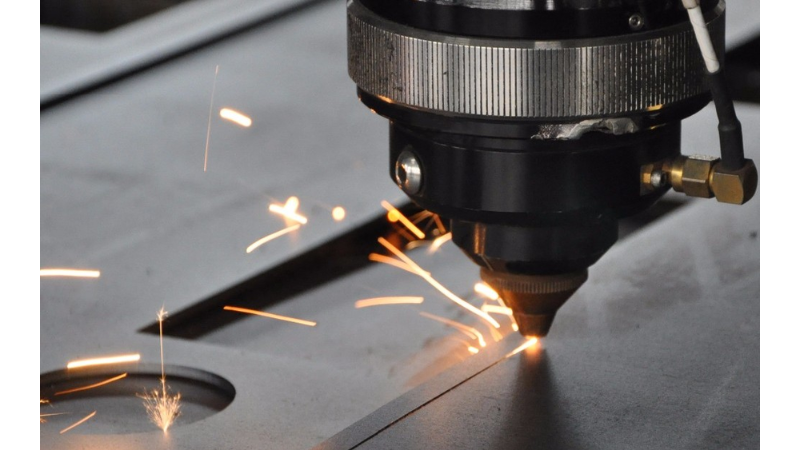

In the world of industrial manufacturing, ensuring the safety of workers is paramount. One of the critical safety measures is the stamping press lockout tagout procedures. These procedures are designed to prevent accidental machine startups, which can lead to severe injuries or fatalities. Understanding and implementing these procedures is essential for maintaining a safe working environment.

Understanding Lockout Tagout (LOTO)

The lockout tagout (LOTO) procedure is a safety protocol used to ensure that dangerous machines are properly shut off and not able to be started up again before the completion of maintenance or repair work. This involves placing a lock on the machine’s power source, preventing it from being turned on, and tagging it to indicate that maintenance is being performed.

Why Are LOTO Procedures Important?

The importance of LOTO procedures cannot be overstated. They protect workers from unexpected machine startups that could cause injuries. These procedures also ensure compliance with safety regulations, reducing the risk of legal liabilities and fines for the companies.

Key Components of Stamping Press LOTO Procedures

Implementing effective stamping press lockout tagout procedures involves several key components:

1. Preparation

Before beginning any maintenance work, it’s crucial to prepare by identifying all energy sources that the stamping press uses. This includes electrical, hydraulic, and pneumatic energy.

2. Notification

Notify all affected employees that the machine will be shut down and locked out. This communication is critical to ensure that no one attempts to use the machine during maintenance.

3. Shutdown

Properly shut down the stamping press according to the manufacturer’s instructions. This step ensures that all energy is safely released.

4. Isolation

Isolate the machine from all energy sources. This involves disconnecting the machine from its power source and ensuring that it cannot be reconnected without proper authorization.

5. Lockout

Apply locks to the power sources to prevent accidental re-energization. Each worker involved in the maintenance should apply their lock to the machine.

6. Tagout

Attach tags to the locks indicating the reason for the lockout and the person responsible. This provides clear information to anyone who comes across the machine.

7. Verification

Once the machine is locked out, verify that it cannot be turned on. This step involves attempting to start the machine to ensure that the lockout is effective.

Best Practices for Implementing LOTO Procedures

To ensure the effectiveness of stamping press lockout tagout procedures, companies should follow these best practices:

Regular Training

Provide regular training sessions for employees on the importance and implementation of LOTO procedures. This keeps safety top of mind and ensures everyone knows how to properly lockout and tagout machines.

Use Standardized Equipment

Use standardized locks and tags to avoid confusion. This makes it easier for employees to understand and comply with LOTO procedures.

Conduct Regular Audits

Regularly audit the LOTO procedures to ensure compliance and identify areas for improvement. This proactive approach helps maintain a safe working environment.

Maintain Clear Documentation

Keep clear documentation of all LOTO procedures, including training records, audit results, and incident reports. This documentation can be invaluable in the event of an accident or audit.

Challenges and Solutions in LOTO Implementation

Implementing stamping press lockout tagout procedures can present challenges. Here are some common challenges and their solutions:

Resistance to Change

Employees may resist new safety protocols. Overcome this by involving them in the development of LOTO procedures and highlighting the benefits of a safe workplace.

Lack of Resources

Ensure that adequate resources, including locks, tags, and training materials, are available. This investment in safety pays off by reducing accidents and downtime.

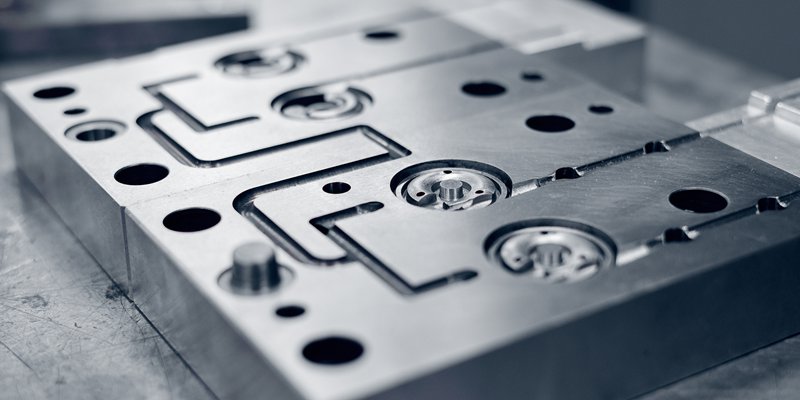

Complex Machinery

Some machinery may be complex, making LOTO implementation challenging. In such cases, work closely with manufacturers and experts to develop customized solutions.

Conclusion

The stamping press lockout tagout procedures are a vital part of maintaining safety in industrial settings. By understanding and implementing these procedures, companies can protect their workers, comply with regulations, and maintain efficient operations. For more information on how a stamping press works, visit Phoenix Specialty.

FAQs

What is the purpose of LOTO procedures?

The purpose of LOTO procedures is to prevent accidental machine startups during maintenance, protecting workers from injuries.

How often should LOTO training be conducted?

LOTO training should be conducted regularly, at least annually, to ensure all employees are familiar with the procedures.

Can LOTO procedures be customized for different machines?

Yes, LOTO procedures should be customized for each machine to account for different energy sources and shutdown methods. For more insights on stamping press productivity, visit Modern Metalworks.

This article contains affiliate links. We may earn a commission at no extra cost to you.