The installation of a stamping press is a critical process in the manufacturing industry. Whether you’re setting up a new facility or upgrading existing equipment, understanding the stamping press installation guide is crucial. This guide aims to provide a comprehensive overview of the steps involved, ensuring a seamless installation process.

Understanding Stamping Presses

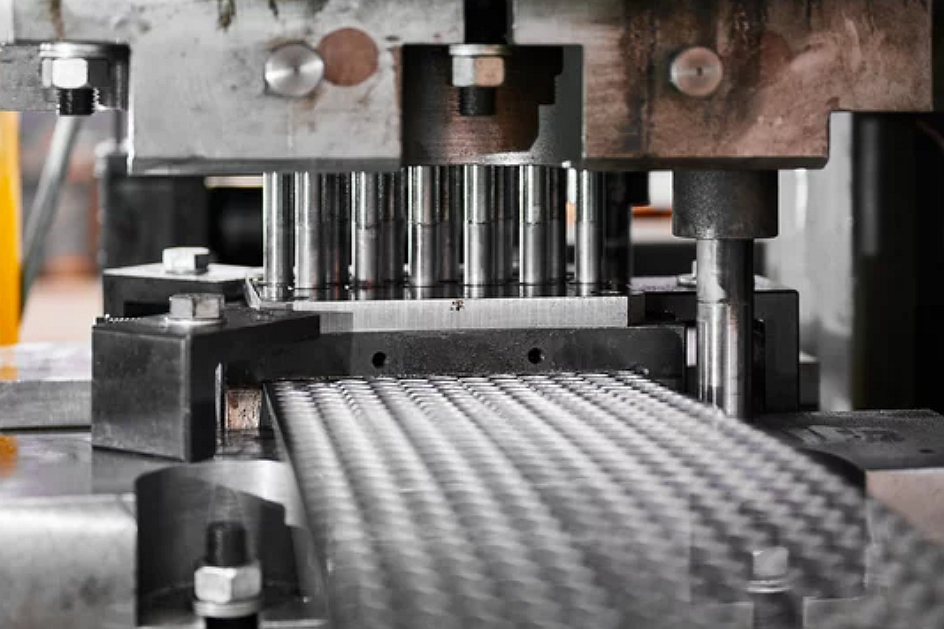

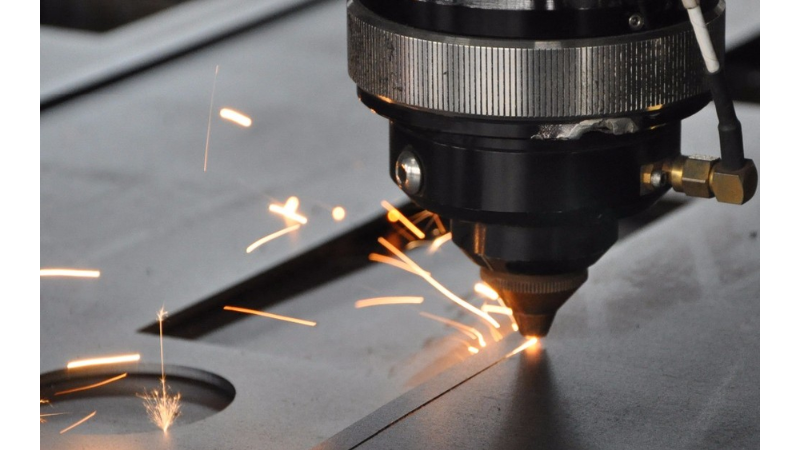

Before delving into the installation process, it’s essential to understand what a stamping press is. A stamping press is a machine used to shape or cut metal by deforming it with a die. These presses are pivotal in creating various metal components used in industries ranging from automotive to consumer electronics.

Types of Stamping Presses

There are several types of stamping presses, each designed for specific applications:

- Mechanical Presses: Known for their speed and precision, they are ideal for high-volume production.

- Hydraulic Presses: Offer greater flexibility and control, making them suitable for deep drawing operations.

- Pneumatic Presses: Used for lighter tasks and smaller production runs.

Preparing for Installation

Preparation is key to a successful installation. Start by assessing the space where the press will be installed. Ensure it’s adequate for the size and type of press. Consider the following:

Space Requirements

Ensure the installation area is spacious enough to accommodate the press and allow for maintenance activities. Consider future expansions and the potential need for additional equipment.

Flooring and Foundation

The flooring must be able to support the weight and vibrations of the press. A reinforced foundation may be required to prevent any structural damage.

Installation Process

The installation process involves several key steps:

Assembling the Press

Once the press components are delivered, begin by assembling them according to the manufacturer’s instructions. This step may require specialized tools and expertise.

Electrical Connections

Proper electrical setup is crucial for the safe operation of the press. Ensure all connections are made by qualified personnel to prevent any electrical hazards.

Calibration and Testing

After assembly, the press must be calibrated to ensure precision in operations. Conduct thorough testing to ensure all systems function correctly.

Safety Considerations

Safety is paramount during the installation and operation of a stamping press. Implement the following safety measures:

Training Personnel

Ensure all operators are adequately trained in the safe operation of the press. Regular safety drills and training sessions can help reinforce best practices.

Regular Maintenance

Implement a maintenance schedule to keep the press in optimal condition. Regular inspections can help identify potential issues before they lead to major failures.

Integrating with Existing Systems

If you’re installing a new press in an existing facility, consider how it will integrate with your current systems. This may involve updating software or modifying production lines.

Automation and Efficiency

Consider integrating automation technologies to enhance productivity. Automated systems can reduce human error and increase operational efficiency.

Common Challenges and Solutions

While installing a stamping press can be complex, being aware of common challenges can help mitigate them:

Dealing with Downtime

Minimize production downtime by scheduling the installation during off-peak hours or over weekends.

Managing Costs

Keep costs in check by sourcing parts and services from reputable suppliers. Consider purchasing used equipment as a cost-effective alternative. For more insights on this, check out used vs new stamping equipment.

FAQs

What is the typical lifespan of a stamping press?

The lifespan of a stamping press can vary based on usage and maintenance but generally ranges from 15 to 20 years.

How often should a stamping press be serviced?

Regular servicing is recommended every six months to ensure optimal performance and safety.

Can a stamping press be relocated?

Yes, but it requires careful planning and execution to prevent damage. Consult with experts to ensure a smooth relocation process.

For more detailed information on stamping presses, visit IQS Directory. Additionally, if you’re interested in improving press productivity, check out our productivity improvement guide.

This article contains affiliate links. We may earn a commission at no extra cost to you.