In the vast world of industrial manufacturing, the role of stamping press drive systems is paramount. These systems are the backbone of metal forming, ensuring precision, efficiency, and reliability in production. For any manufacturer aiming to enhance their production capabilities, understanding these drive systems is crucial.

What Are Stamping Press Drive Systems?

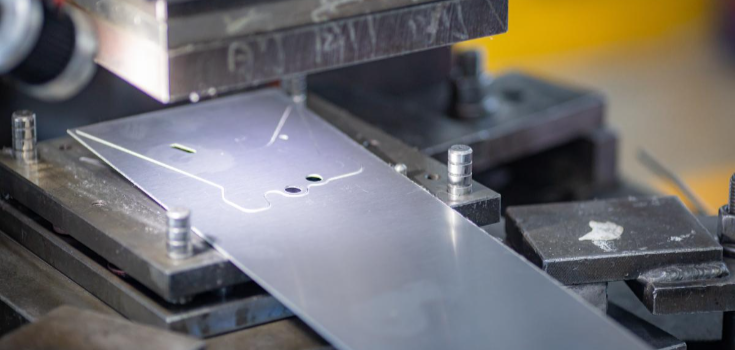

At the core, stamping press drive systems are mechanisms that power stamping presses. These machines are used to shape or cut metal by deforming it with a die. The drive system controls the motion and force, making sure each piece is consistent and meets quality standards. Without these systems, the precision required in industries like medical device stamping would be impossible.

Types of Stamping Press Drive Systems

There are several types of drive systems used in the industry, each suited for different applications:

- Mechanical Presses: Traditional and reliable, they use a flywheel to store energy and deliver it in a single, powerful stroke.

- Hydraulic Presses: Utilize hydraulic cylinders to exert force, offering more control and flexibility than mechanical presses.

- Servo Presses: The most advanced, they use servo motors for precision control, making them ideal for complex and delicate stamping tasks.

Benefits of Modern Stamping Press Drive Systems

Modern stamping press drive systems offer numerous advantages:

Increased Efficiency

These systems are designed to maximize throughput, reducing cycle times and increasing overall production efficiency. This efficiency is crucial for industries looking to improve stamping press productivity.

Enhanced Precision

With advanced control mechanisms, manufacturers can achieve tighter tolerances, ensuring each stamped part meets exact specifications. This precision is vital in sectors like consumer electronics stamping.

Improved Safety

Modern systems come with enhanced safety features, protecting operators and reducing the risk of accidents. Safety is always a priority in quality control.

Choosing the Right Stamping Press Drive System

Selecting the right system depends on several factors:

Material Type

The type of material being stamped will influence the choice of drive system. Different materials require different force and speed settings.

Production Volume

For high-volume production, systems that offer faster cycle times and greater efficiency are preferred.

Budget Constraints

While advanced systems like servo presses offer many benefits, they come at a higher cost. Manufacturers must balance their needs with their budget.

Maintenance of Stamping Press Drive Systems

Regular maintenance is essential to keep stamping press drive systems running smoothly. This includes:

Routine Inspections

Regular checks can identify wear and tear, preventing costly downtime. This proactive approach is crucial for maintaining stamping equipment.

Lubrication

Proper lubrication reduces friction and wear, extending the lifespan of the system components.

Component Replacement

Timely replacement of worn components prevents breakdowns and ensures consistent production quality.

The Future of Stamping Press Drive Systems

As technology advances, stamping press drive systems will continue to evolve. Future trends include:

Integration with IoT

The Internet of Things (IoT) will allow for real-time monitoring and predictive maintenance, further enhancing efficiency and reliability.

Automation

Increased automation will reduce the need for manual intervention, improving safety and reducing labor costs.

Environmental Considerations

Future systems will focus on reducing energy consumption and minimizing environmental impact, aligning with global sustainability goals.

Conclusion

The world of stamping press drive systems is dynamic and ever-evolving. For industrial manufacturers, understanding these systems is key to staying competitive in the market. By embracing modern technologies and focusing on efficiency, precision, and safety, manufacturers can ensure their operations remain at the forefront of the industry.

FAQs

What is the primary function of stamping press drive systems?

The primary function of stamping press drive systems is to power stamping presses, ensuring precise and efficient metal forming operations.

Which drive system is best for high precision tasks?

Servo presses are best suited for high precision tasks due to their advanced control mechanisms.

How can I improve the efficiency of my stamping press?

Regular maintenance, choosing the right drive system, and integrating modern technologies can significantly improve the efficiency of stamping presses.

For more insights into metal stamping processes, you can visit Metal Stamping 101.

This article contains affiliate links. We may earn a commission at no extra cost to you.