In the world of industrial manufacturing, efficiency and productivity are paramount. One critical aspect of achieving these goals is through stamping press cycle time optimization. By understanding and implementing strategies to optimize cycle time, manufacturers can significantly improve their production processes, reduce costs, and enhance overall productivity.

Understanding Stamping Press Cycle Time

Cycle time refers to the total time it takes to complete one full cycle of operation in a stamping press. This includes all stages of the process, from loading the material to the final release of the stamped product. Optimizing this time is essential for maximizing efficiency and throughput.

The Importance of Cycle Time in Manufacturing

In manufacturing, every second counts. Reducing cycle time can lead to increased production rates and lower operational costs. It also allows manufacturers to respond more swiftly to market demands and maintain a competitive edge in the industry.

Key Factors Influencing Cycle Time

Several factors can affect the cycle time of a stamping press. Understanding these elements is crucial for effective optimization:

1. Equipment Efficiency

The efficiency of the stamping equipment plays a significant role in cycle time. Regular maintenance and upgrades can prevent downtime and ensure the equipment operates at peak performance.

2. Material Handling

Efficient material handling systems can drastically reduce cycle time. Automated systems that quickly and accurately load and unload materials can prevent bottlenecks in the production process.

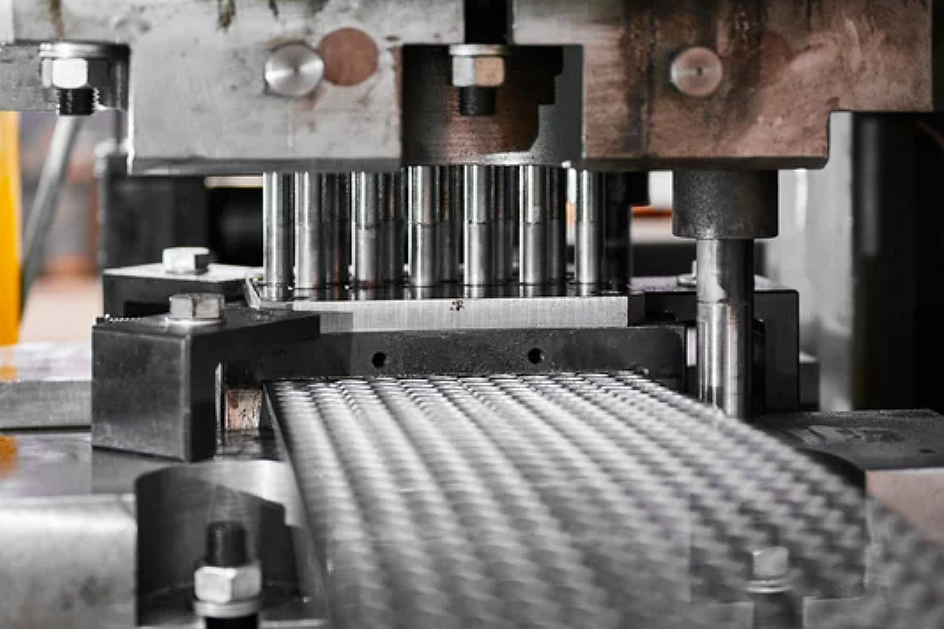

3. Tooling Design

Well-designed tooling can minimize the time required for each stamping operation. Precision tooling reduces the need for adjustments and improves the quality of the final product.

4. Operator Skill

Skilled operators who are well-trained in the use of stamping equipment can significantly reduce cycle time. Their expertise allows for quicker setup times and more efficient troubleshooting.

Strategies for Optimizing Stamping Press Cycle Time

Implementing the right strategies can lead to significant improvements in cycle time:

1. Regular Maintenance and Upgrades

Routine maintenance and timely upgrades of stamping equipment can prevent unexpected breakdowns and ensure smooth operations. This is crucial for maintaining optimal cycle time.

2. Automation and Robotics

Integrating automation and robotics into the stamping process can streamline operations and reduce cycle time. Automated systems can handle repetitive tasks with precision and speed.

3. Lean Manufacturing Techniques

Adopting lean manufacturing techniques can identify and eliminate waste in the production process. This approach focuses on maximizing value while minimizing waste, leading to faster cycle times.

4. Continuous Training and Development

Investing in continuous training for operators ensures that they remain skilled and knowledgeable about the latest technologies and techniques. This can lead to more efficient operations and reduced cycle time.

The Role of Technology in Cycle Time Optimization

Technology plays a vital role in optimizing cycle time in stamping press operations:

1. Monitoring and Analytics

Advanced monitoring systems and analytics tools can provide real-time data on equipment performance and cycle time. This information is invaluable for identifying areas for improvement.

2. Predictive Maintenance

Predictive maintenance uses data analytics to anticipate equipment failures before they occur. This proactive approach minimizes downtime and keeps cycle time in check.

3. Smart Manufacturing Solutions

Smart manufacturing solutions leverage the power of IoT (Internet of Things) to connect equipment and systems. This connectivity allows for seamless communication and coordination, further optimizing cycle time.

Benefits of Optimizing Stamping Press Cycle Time

Optimizing cycle time in stamping press operations offers numerous benefits:

1. Increased Productivity

Faster cycle times mean higher production rates and increased productivity, allowing manufacturers to meet customer demands more efficiently.

2. Reduced Costs

By minimizing downtime and maximizing efficiency, manufacturers can significantly reduce operational costs and improve profitability.

3. Improved Quality

Efficient processes often lead to improved product quality, as there is less room for errors and defects in streamlined operations.

Conclusion

In conclusion, stamping press cycle time optimization is a critical factor in enhancing productivity and efficiency in industrial manufacturing. By understanding the key factors influencing cycle time and implementing effective strategies, manufacturers can unlock significant improvements in their operations. Embracing technology and continuous improvement will pave the way for a more competitive and successful future in the manufacturing industry.

Additional Resources

For more insights on stamping press operations, consider exploring this external resource.

Additionally, you can find valuable information on related topics such as consumer electronics, medical devices, and equipment choices.

FAQs

What is stamping press cycle time?

Stamping press cycle time refers to the total duration required to complete one cycle of stamping operation, from loading to final product release.

How can I reduce cycle time in my stamping operations?

Reducing cycle time can be achieved through equipment maintenance, automation, lean techniques, and continuous operator training.

Why is cycle time optimization important?

Optimizing cycle time is crucial for improving productivity, reducing costs, and enhancing product quality in manufacturing processes.

This article contains affiliate links. We may earn a commission at no extra cost to you.