In the world of manufacturing, the importance of stamping press coatings for lightweight metals cannot be overstated. As industries strive to enhance efficiency and product quality, these coatings play a crucial role. This article explores the nuances of stamping press coatings and their impact on lightweight metals.

Understanding Stamping Press Coatings

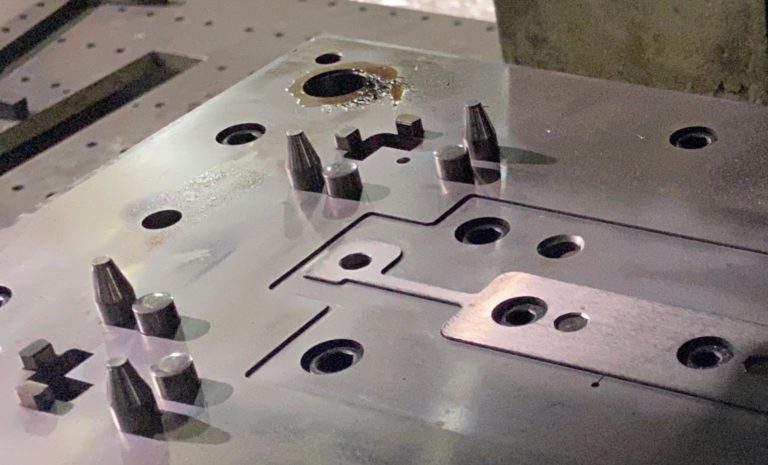

Stamping press coatings are specialized materials applied to the surface of stamping equipment. These coatings are designed to improve the performance and longevity of the machinery, especially when working with lightweight metals like aluminum and magnesium.

Why Coatings Matter

The primary function of these coatings is to reduce friction between the stamping press and the metal. This reduction in friction leads to less wear and tear on the equipment, thus extending its lifespan. Additionally, coatings can enhance the quality of the stamped products by ensuring cleaner cuts and reducing the risk of defects.

Types of Coatings Used in Stamping Presses

There are several types of coatings used in stamping presses, each offering unique benefits:

- TiN (Titanium Nitride): Known for its hardness and wear resistance, TiN is a popular choice for stamping tools.

- CrN (Chromium Nitride): Offers excellent corrosion resistance, making it ideal for environments prone to moisture.

- Diamond-like Carbon (DLC): Provides a low-friction surface, reducing the heat produced during stamping.

The Role of Coatings in Lightweight Metal Stamping

Lightweight metals are increasingly used in various industries due to their strength-to-weight ratio. However, these metals present unique challenges during the stamping process.

Challenges in Stamping Lightweight Metals

Lightweight metals are often softer and more prone to deformation compared to traditional metals. This characteristic can lead to increased wear on stamping tools and a higher likelihood of defects in the final product.

How Coatings Address These Challenges

By applying the right coatings to stamping presses, manufacturers can mitigate these challenges. Coatings reduce the friction and heat generated during the stamping process, minimizing the risk of deformation and wear on the tools.

Benefits of Using Coatings in Stamping Presses

The benefits of using coatings in stamping presses extend beyond just tool longevity. They also include:

Improved Product Quality

Coatings ensure cleaner and more precise cuts, reducing the risk of defects and improving the overall quality of the stamped products.

Increased Efficiency

With reduced friction and wear, stamping presses can operate at higher speeds, increasing production efficiency.

Cost Savings

By extending the life of stamping tools and reducing the likelihood of defects, coatings can lead to significant cost savings for manufacturers.

Choosing the Right Coating for Your Stamping Press

When selecting a coating for your stamping press, it’s essential to consider the specific needs of your operation. Factors to consider include:

- The type of metal being stamped.

- The production volume and speed.

- The environmental conditions of the manufacturing facility.

Consulting with Experts

For optimal results, it’s advisable to consult with experts in the field of stamping press coatings. They can provide insights and recommendations tailored to your specific needs.

Case Studies: Success Stories in Stamping Press Coatings

Many manufacturers have successfully implemented stamping press coatings with positive results. For instance, a leading automotive manufacturer reported a 30% increase in production efficiency after adopting TiN coatings for their stamping presses.

Future Trends in Stamping Press Coatings

The future of stamping press coatings looks promising, with ongoing research and development focused on creating even more effective solutions. Emerging technologies, such as nanocoatings, hold the potential to revolutionize the industry.

Environmental Considerations

As sustainability becomes a priority, manufacturers are exploring eco-friendly coating options that minimize environmental impact while maintaining performance.

Conclusion: The Impact of Coatings on Lightweight Metal Stamping

In conclusion, stamping press coatings play a vital role in enhancing the performance and efficiency of manufacturing processes involving lightweight metals. By choosing the right coatings and staying informed about industry trends, manufacturers can achieve significant improvements in product quality and operational efficiency.

Further Reading and Resources

For more information on stamping press technology, consider visiting this external resource. Additionally, explore internal resources like productivity improvement and monitoring systems on the Modern Metalworks website.

FAQs

What are the main types of coatings used in stamping presses?

Common types include Titanium Nitride (TiN), Chromium Nitride (CrN), and Diamond-like Carbon (DLC) coatings.

How do coatings enhance the stamping process?

They reduce friction, extend tool life, and improve the quality of stamped products by minimizing defects.

What should manufacturers consider when selecting a coating?

Factors include the type of metal being stamped, production volume, speed, and environmental conditions of the facility.

This article contains affiliate links. We may earn a commission at no extra cost to you.