In the dynamic world of industrial manufacturing, stamping machine operator training plays a pivotal role in ensuring efficiency and safety. As the demand for high-quality stamped products rises, the need for skilled operators becomes increasingly crucial. This article delves into the essentials of training, providing insights that can help manufacturers maintain a competitive edge.

Understanding the Role of a Stamping Machine Operator

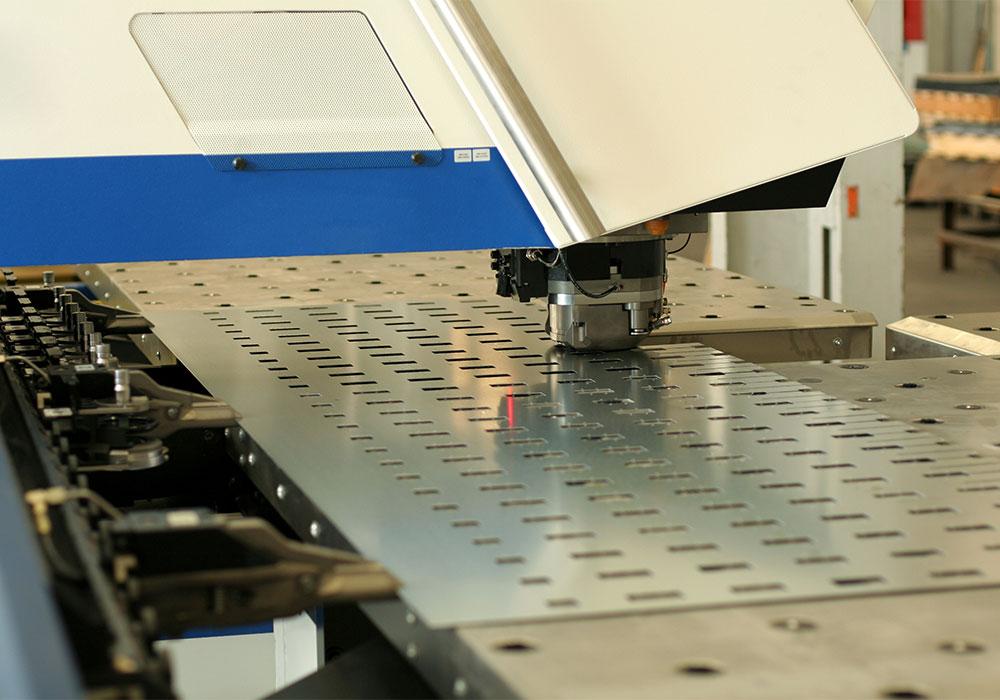

A stamping machine operator is responsible for operating machines that shape and cut metal or other materials. These professionals ensure that products meet specified standards and are produced efficiently. Proper training empowers operators to excel in their roles, enhancing both productivity and safety.

Why is Training Essential?

Training is essential because it equips operators with the necessary skills to handle complex machinery safely and efficiently. Without proper training, the risk of machine errors, accidents, and product defects increases significantly. Comprehensive training programs cover various aspects, including machine operation, safety protocols, and troubleshooting techniques.

Components of a Comprehensive Training Program

An effective training program comprises several key components:

- Technical Knowledge: Understanding the mechanics and functions of stamping machines.

- Safety Procedures: Emphasizing the importance of safety measures to prevent accidents.

- Troubleshooting Skills: Developing the ability to diagnose and resolve machine issues swiftly.

- Quality Control: Ensuring products meet quality standards, as detailed in quality control measures.

Technical Skills Acquired During Training

Training imparts a wide range of technical skills essential for efficient machine operation. Operators learn to interpret technical drawings, operate different types of stamping machines, and perform routine maintenance checks. These skills contribute to the seamless production of high-quality stamped components.

Safety First: A Core Aspect of Training

Safety is a paramount concern in the industrial sector. Training programs emphasize the importance of adhering to safety guidelines to prevent workplace accidents. Operators learn about personal protective equipment (PPE), emergency procedures, and safe machine handling practices.

Practical Training: Bridging Theory and Reality

While theoretical knowledge is vital, practical training bridges the gap between theory and real-world application. Hands-on experience allows operators to apply what they have learned in a controlled environment, boosting their confidence and competence in handling stamping machines.

Ongoing Training: Adapting to Technological Advances

The industrial landscape is continually evolving with technological advancements. Ongoing training ensures that operators stay updated with the latest machine technologies and production techniques, enhancing their ability to contribute effectively to the manufacturing process.

Certification: Validating Competence

Certification is a testament to an operator’s skills and knowledge. It serves as a valuable credential, showcasing their ability to perform tasks efficiently and safely. Employers often prefer certified operators, as it assures them of a high level of competence and professionalism.

Choosing the Right Training Program

Selecting the right training program is crucial for aspiring operators. Factors to consider include the program’s curriculum, reputation, and alignment with industry standards. It’s advisable to choose programs that offer a blend of theoretical and practical training, ensuring comprehensive skill development.

Benefits of Well-Trained Operators

Well-trained operators bring numerous benefits to the manufacturing process. They increase production efficiency, reduce machine downtime, and contribute to higher product quality. Moreover, they enhance workplace safety, reducing the likelihood of accidents and injuries.

Challenges in Training and Solutions

Training operators can present challenges, such as varying skill levels and resistance to change. Solutions include personalized training approaches, continuous learning opportunities, and fostering a positive learning environment. Emphasizing the long-term benefits of training can also motivate operators to embrace it.

Conclusion: Investing in the Future of Manufacturing

In conclusion, stamping machine operator training is a critical investment for any manufacturing company. It not only ensures the efficient operation of machines but also enhances product quality and workplace safety. As the industry continues to evolve, ongoing training becomes indispensable, empowering operators to adapt and thrive in a competitive market.

FAQs

1. What does a stamping machine operator do?

A stamping machine operator is responsible for setting up, operating, and maintaining machines that cut and shape materials into parts or products.

2. Why is training important for stamping machine operators?

Training is crucial as it equips operators with the necessary skills to handle machinery safely and effectively, reducing the risk of errors and accidents.

3. How can I choose the right training program?

Consider programs that offer a blend of theoretical and practical training, have a good reputation, and align with industry standards.

This article contains affiliate links. We may earn a commission at no extra cost to you.