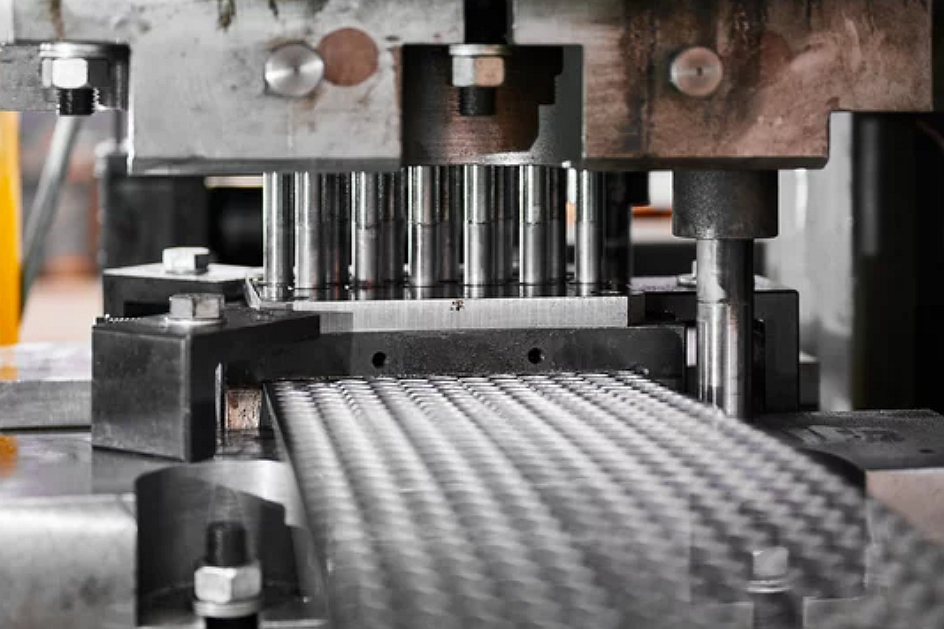

In the world of industrial manufacturing, the longevity and efficiency of equipment are pivotal for maintaining productivity and cost-effectiveness. One of the most critical components in this realm is the stamping die. These dies are essential for shaping and cutting materials in mass production, but over time, they undergo wear and tear. Addressing these issues is crucial, and finding stamping die wear and tear solutions can significantly enhance the lifespan and performance of these tools.

The deterioration of stamping dies can lead to inefficient production, increased maintenance costs, and potential downtime. Therefore, understanding the causes of wear and implementing effective solutions is vital. This article explores various strategies and techniques to mitigate the wear and tear of stamping dies.

Understanding Stamping Die Wear

Stamping die wear occurs due to various factors, including friction, pressure, and material properties. Dies are subjected to repetitive mechanical stress, leading to gradual degradation. This wear can manifest as surface abrasion, thermal fatigue, or even cracking. Identifying the type of wear is the first step in devising effective solutions.

Factors Contributing to Wear

Several factors contribute to the wear and tear of stamping dies, including:

- Material Hardness: The hardness of the material being stamped can accelerate wear.

- Lubrication: Inadequate lubrication increases friction, leading to faster wear.

- Die Design: Poor design can lead to uneven stress distribution, exacerbating wear.

Solutions for Stamping Die Wear and Tear

Implementing the right solutions can significantly reduce the wear and tear of stamping dies. Below are some effective strategies:

Material Selection

Choosing the right material for both the die and the material being stamped is crucial. High-quality, wear-resistant materials can enhance the durability of the die.

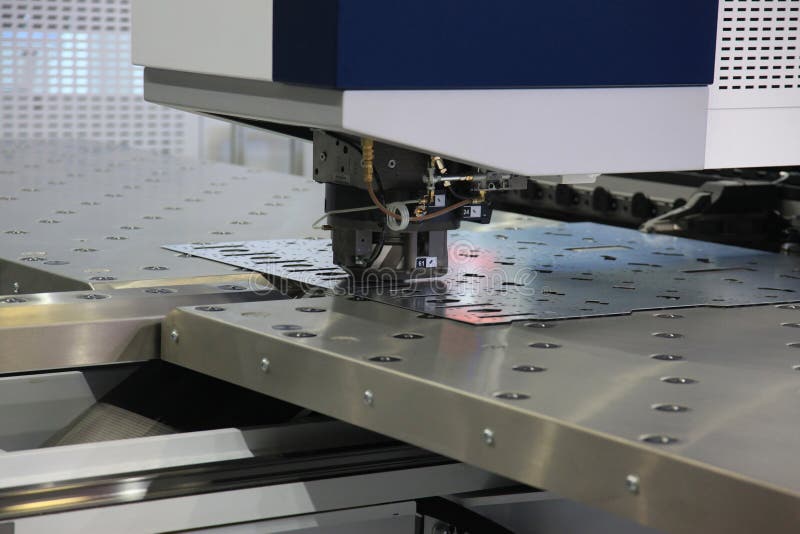

Die Design Optimization

Optimizing die design to ensure uniform stress distribution can minimize wear. This includes proper alignment and precise cutting angles.

Regular Maintenance

Regular maintenance and inspections can help identify early signs of wear, allowing for timely interventions.

Use of Coatings

Applying protective coatings can reduce friction and improve the wear resistance of stamping dies.

Advanced Techniques and Technologies

With advancements in technology, several innovative techniques have emerged to combat die wear. These include:

Laser Hardening

This technique involves using lasers to harden the surface of the dies, enhancing their resistance to wear.

Cryogenic Treatment

Cryogenic treatment involves exposing dies to extremely low temperatures, improving their microstructure and wear resistance.

Training and Safety

Proper operator training and adherence to safety protocols can prevent operational errors that may lead to premature die wear.

Environmental Considerations

Environmental factors such as temperature and humidity can affect die performance. Ensuring optimal environmental conditions can mitigate wear.

Cost Implications

While implementing these solutions may incur initial costs, the long-term benefits of reduced maintenance and increased die lifespan outweigh these expenses.

The Future of Stamping Die Solutions

As technology continues to evolve, new solutions are anticipated in the field of stamping die wear and tear. Continuous research and development will pave the way for more durable and efficient dies.

Conclusion

Addressing stamping die wear and tear is essential for maintaining the efficiency and cost-effectiveness of manufacturing processes. By understanding the causes of wear and implementing the right solutions, manufacturers can significantly enhance the lifespan and performance of their stamping dies.

FAQs

Q1: What are the common causes of stamping die wear?

A: Common causes include friction, material hardness, and inadequate lubrication.

Q2: How can regular maintenance help reduce die wear?

A: Regular maintenance can identify early signs of wear, allowing for timely interventions.

Q3: What are the benefits of using protective coatings on dies?

A: Protective coatings can reduce friction and improve the wear resistance of stamping dies.

For more insights on metal stamping, check out this informative article on hot metal stamping.

This article contains affiliate links. We may earn a commission at no extra cost to you.