In the world of industrial manufacturing, ensuring the longevity and efficiency of stamping dies is crucial. This stamping die maintenance guide is designed to help manufacturers maintain their tools effectively, ensuring consistent quality and reducing downtime. Whether you’re new to the field or a seasoned professional, understanding the nuances of die maintenance can significantly impact your operations.

Understanding Stamping Dies

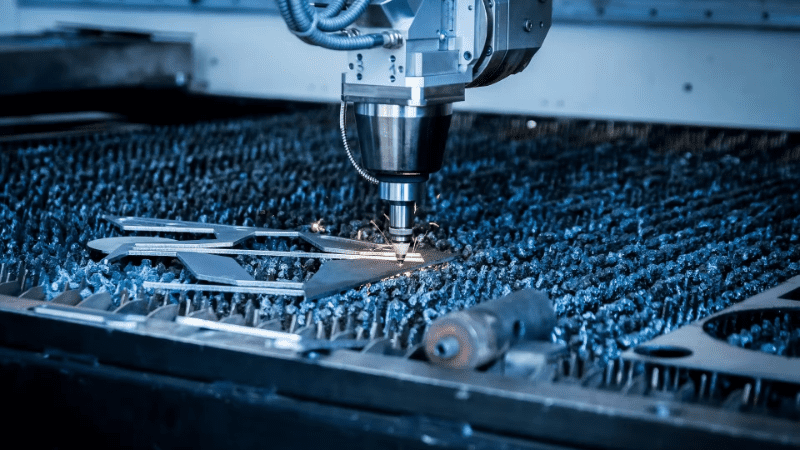

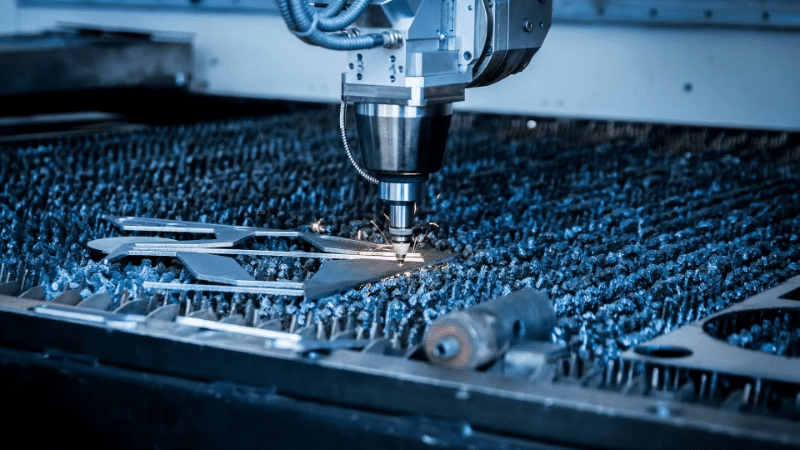

Before diving into maintenance, it’s essential to comprehend what stamping dies are and their role in manufacturing. Stamping dies are specialized tools used to cut and form sheet metal into specific shapes. They are a fundamental component in the production of various metal parts, from automotive components to household appliances.

The Importance of Maintenance

Proper maintenance of stamping dies is not just about extending their lifespan but also about ensuring the quality of the products they manufacture. Regular maintenance can prevent issues such as misalignment, wear, and damage, which can lead to defective products and costly downtime.

Essential Maintenance Tips

Regular Inspection

One of the most crucial steps in stamping die maintenance is regular inspection. Inspecting dies for signs of wear, damage, or misalignment can help identify problems before they escalate. Look for cracks, chips, or uneven wear on the die surfaces.

Cleaning and Lubrication

Keeping the dies clean and well-lubricated is vital. Dirt and debris can cause abrasion and wear, while proper lubrication reduces friction and wear during operation. Use appropriate cleaning solutions and lubricants recommended by the die manufacturer.

Proper Storage

How you store your stamping dies can also affect their longevity. Store them in a clean, dry environment, and protect them from moisture and dust. Use protective covers or cases to prevent accidental damage.

Tool Sharpening

Regular sharpening of cutting edges is necessary to maintain precision and efficiency. Dull edges can lead to poor-quality cuts and increased wear on the dies. Follow the manufacturer’s guidelines for sharpening frequency and techniques.

Advanced Maintenance Techniques

Die Alignment

Ensuring proper alignment of the dies is crucial for accurate stamping. Misalignment can cause uneven wear and damage to both the die and the stamped parts. Use precision tools to check and adjust the alignment regularly.

Surface Coatings

Applying protective coatings to the die surfaces can enhance their durability and resistance to wear. Coatings such as titanium nitride (TiN) or diamond-like carbon (DLC) can significantly increase the lifespan of the dies.

Die Set Maintenance

In addition to the dies themselves, maintaining the die sets is equally important. Ensure that the die holders, guide pins, and bushings are in good condition and free from wear or damage.

Common Maintenance Challenges

Wear and Tear

Natural wear and tear are inevitable in any manufacturing process. However, by following a regular maintenance schedule and using high-quality materials, you can minimize wear and extend the life of your stamping dies.

Environmental Factors

Environmental conditions, such as temperature and humidity, can affect the performance and longevity of stamping dies. Ensure that your manufacturing environment is controlled and that your dies are protected from extreme conditions.

Integrating Technology in Maintenance

Use of Sensors

Modern technology offers innovative solutions for stamping die maintenance. Sensors can monitor the condition of dies in real-time, alerting you to potential issues before they become significant problems.

Predictive Maintenance

Predictive maintenance uses data analysis to predict when maintenance should be performed. This approach can help prevent unexpected failures and optimize the maintenance schedule for your stamping dies.

Training and Skill Development

Employee Training

Ensuring that your team is well-trained in die maintenance procedures is vital. Regular training sessions and workshops can keep your staff updated on the latest maintenance techniques and technologies.

Skill Development

Encouraging continuous skill development among your employees can lead to more efficient and effective stamping die maintenance. Keep an eye on industry trends and advancements to stay ahead of the curve.

Conclusion

In conclusion, maintaining stamping dies is a critical aspect of the manufacturing process. By following this stamping die maintenance guide, you can ensure the longevity and efficiency of your tools, leading to high-quality products and reduced downtime. Embrace modern technologies, invest in employee training, and adhere to a regular maintenance schedule to keep your operations running smoothly. For more insights, you might want to check this Metal Stamping Process blog.

FAQ

What are the signs of die wear?

Signs of die wear include cracks, chips, uneven wear on the die surfaces, and poor-quality stamped parts.

How often should stamping dies be inspected?

Stamping dies should be inspected regularly, with the frequency depending on the production volume and material used. A general rule of thumb is to inspect them after every few thousand cycles.

Can technology improve die maintenance?

Yes, integrating technology such as sensors and predictive maintenance can significantly improve the efficiency and effectiveness of die maintenance.

For related projects, check out our Garden Art and Metal Mosaic ideas that showcase the versatility of metalworking.

This article contains affiliate links. We may earn a commission at no extra cost to you.