In today’s fast-paced industrial world, stamping die design software plays a pivotal role in enhancing the precision and efficiency of manufacturing processes. For industrial manufacturers seeking to optimize their production lines, understanding the capabilities and benefits of this software is essential. By leveraging advanced technologies, these tools have transformed how companies approach die design, leading to significant improvements in productivity and quality.

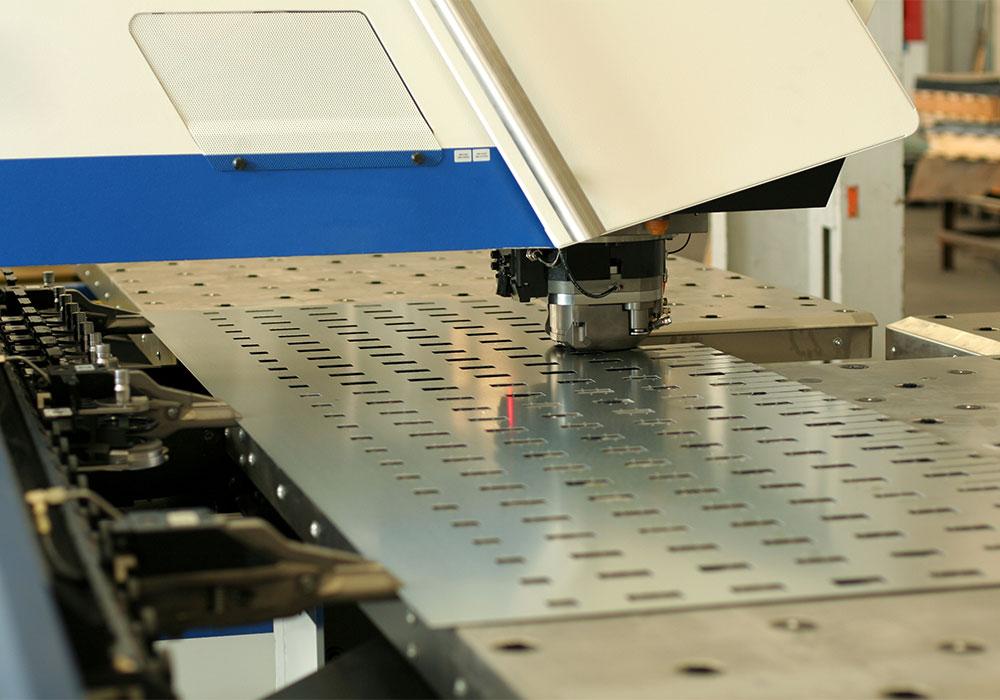

For those unfamiliar with the concept, stamping die design software encompasses a range of digital tools that assist in creating and optimizing the dies used in metal stamping processes. These dies are critical components in shaping and cutting metal sheets into desired forms, making them a cornerstone of manufacturing operations.

The Role of Stamping Die Design Software

The primary function of stamping die design software is to streamline the design and development of dies. By providing detailed models and simulations, these tools enable engineers to visualize and refine their designs before physical production begins. This capability not only saves time but also reduces the risk of costly errors.

Enhanced Precision and Efficiency

One of the standout features of stamping die design software is its ability to deliver exceptional precision. By offering detailed insights into the design process, manufacturers can ensure that each die meets the exact specifications required for their products. This precision translates into higher-quality output and fewer defects.

Cost Reduction

Another significant advantage of using stamping die design software is cost reduction. By optimizing designs and minimizing material waste, companies can significantly lower their production costs. This not only enhances profitability but also ensures a more sustainable approach to manufacturing.

Key Features of Stamping Die Design Software

When evaluating different stamping die design software options, it’s important to consider the key features that set them apart. Here are some of the most important aspects to look for:

3D Modeling and Simulation

Advanced stamping die design software offers robust 3D modeling capabilities. This feature allows engineers to create detailed virtual prototypes and simulate real-world conditions, ensuring that the final design performs as expected.

Material Optimization

Material optimization is a critical component of effective die design. With stamping die design software, manufacturers can analyze material properties and determine the most efficient way to use resources, reducing waste and cutting costs.

Integration with CAD/CAM Systems

Seamless integration with existing CAD/CAM systems is crucial for maximizing the benefits of stamping die design software. This compatibility ensures a smooth transition from design to production, enhancing overall workflow efficiency.

Benefits of Implementing Stamping Die Design Software

The adoption of stamping die design software brings numerous benefits to manufacturers. Here are some of the most notable advantages:

Improved Product Quality

By enabling precise control over the design process, stamping die design software helps ensure that the final products meet the highest quality standards. This leads to greater customer satisfaction and a stronger reputation in the market.

Faster Time-to-Market

Speed is a critical factor in today’s competitive manufacturing landscape. With stamping die design software, companies can accelerate the design and production process, bringing products to market faster and gaining a competitive edge.

Enhanced Collaboration

Modern stamping die design software often includes collaboration tools that facilitate communication between team members. This enhances teamwork and ensures that everyone is aligned throughout the design and production phases.

Choosing the Right Stamping Die Design Software

Selecting the appropriate stamping die design software for your business requires careful consideration of various factors. Here are some key points to keep in mind:

Assess Your Needs

Before investing in stamping die design software, evaluate your specific needs and requirements. Consider factors such as the complexity of your designs, the size of your team, and your budget constraints.

Evaluate Features and Functionality

Look for software that offers the features and functionality that align with your goals. This includes 3D modeling, simulation capabilities, and integration options.

Consider User Experience

The ease of use is an important factor when selecting stamping die design software. Choose a solution that is intuitive and user-friendly, ensuring that your team can quickly adapt and maximize its potential.

Conclusion

In conclusion, stamping die design software is an invaluable tool for industrial manufacturers seeking to enhance their precision and efficiency. By leveraging advanced features such as 3D modeling and material optimization, companies can achieve higher-quality output and reduce costs. When selecting the right software, it’s important to evaluate your specific needs and consider factors such as user experience and integration capabilities.

For more insights on improving your production productivity and exploring the latest trends in metal stamping, visit Modern Metalworks. Additionally, you can learn about the basics of metal stamping by checking out this informative guide.

FAQ

What is stamping die design software?

Stamping die design software is a digital tool used by manufacturers to create and optimize the dies used in metal stamping processes. It provides detailed models and simulations to enhance precision and efficiency.

How does stamping die design software improve quality?

By offering precise control over the design process, stamping die design software helps ensure that the final products meet high-quality standards, leading to greater customer satisfaction.

What are the benefits of using stamping die design software?

The benefits include improved product quality, faster time-to-market, cost reduction, and enhanced collaboration among team members.

This article contains affiliate links. We may earn a commission at no extra cost to you.