In the world of industrial manufacturing, the stamping die clearance calculation is a critical component that determines the quality and efficiency of the metal stamping process. Proper clearance ensures that the metal is cut cleanly and precisely, reducing wear on the die and preventing issues like burrs or deformation. Understanding how to calculate and apply the right clearance can significantly impact the productivity and longevity of stamping operations.

What is Stamping Die Clearance?

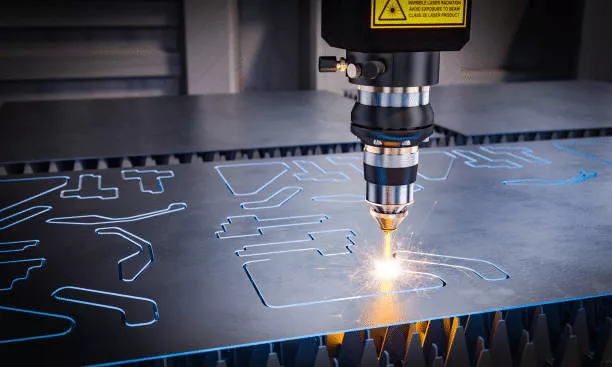

Stamping die clearance refers to the gap between the die and the punch in a stamping operation. This clearance is crucial for the metal cutting process, influencing factors like the quality of the cut edge and the force required for the operation. Proper clearance helps maintain the structural integrity of the metal piece and enhances the overall efficiency of the stamping process.

Importance of Accurate Die Clearance

Accurate die clearance is essential for several reasons. It minimizes the risk of burr formation, reduces tool wear, and ensures a smooth cutting process. Incorrect clearance can lead to increased maintenance costs and downtime, impacting overall production efficiency. Understanding the principles of accurate clearance calculation is vital for any manufacturing setup.

Factors Influencing Die Clearance

Several factors influence the determination of die clearance. Material thickness, type, and the desired edge quality are primary considerations. The nature of the material, whether it’s soft like aluminum or hard like stainless steel, will affect the amount of clearance needed. Additionally, the thickness of the material directly correlates with the amount of clearance required for optimal results.

Methods for Calculating Die Clearance

Various methods can be employed to calculate die clearance, each with its advantages. The most common approach is the percentage of material thickness, typically ranging from 5% to 20% depending on the material and application. Advanced techniques involve using specialized software and tools that factor in material properties and desired outcomes for more precise calculations.

Percentage of Material Thickness Method

This method involves calculating clearance as a percentage of the material thickness. For example, if the material is 1 mm thick, and the desired clearance is 10%, the clearance would be 0.1 mm. This method is straightforward and widely used for its simplicity and effectiveness.

Software and Advanced Tools

For more complex operations, using specialized software can enhance accuracy. These tools incorporate various parameters, such as material properties, edge quality requirements, and machine capabilities, to deliver precise clearance calculations. This approach is beneficial for high-volume or high-precision operations where even minor deviations can impact quality and efficiency.

Impact of Die Clearance on Product Quality

The correct die clearance directly impacts the quality of the stamped product. Proper clearance results in clean cuts, reducing the need for secondary operations like deburring. This not only improves the visual and structural quality of the product but also enhances production efficiency by minimizing rework and material wastage.

Burr Formation and Its Prevention

Burrs are unwanted projections of material that can form on the edges of stamped parts. They are often a result of incorrect die clearance. Proper calculation and adjustment of clearance can significantly reduce or eliminate burr formation, saving time and resources in the manufacturing process.

Optimizing Stamping Operations

Optimizing stamping operations involves not only accurate die clearance but also regular maintenance and monitoring. Implementing advanced monitoring systems can help detect wear and tear early, preventing unexpected downtime. Additionally, understanding the role of productivity improvement techniques can further enhance operational efficiency.

Common Challenges in Die Clearance Calculation

Despite its importance, die clearance calculation can present challenges. Variability in material properties, machine wear, and operator expertise can all influence the accuracy of clearance calculations. Addressing these challenges involves continuous learning and adaptation, as well as leveraging technology and expertise to ensure precision and reliability.

Material Variability

Materials can vary significantly in terms of hardness, composition, and thickness, affecting the required clearance. Manufacturers must consider these variations when calculating and adjusting die clearance to maintain consistency and quality.

Machine Wear and Maintenance

Over time, machines can experience wear that affects their performance and the accuracy of stamping operations. Regular maintenance, coupled with precise die clearance adjustments, is essential to mitigate these effects and maintain optimal production conditions.

Technological Advancements in Die Clearance

Technological advancements have revolutionized die clearance calculation. From computer-aided design (CAD) software to real-time monitoring systems, technology provides valuable tools for enhancing accuracy and efficiency in stamping operations. Embracing these innovations can lead to significant improvements in quality and productivity.

Computer-Aided Design (CAD)

CAD software allows for precise modeling and simulation of the stamping process, enabling accurate clearance calculation and adjustment. This technology helps in visualizing the effects of different clearances and optimizing them for specific applications.

Real-Time Monitoring Systems

Real-time monitoring systems provide continuous feedback on machine performance and product quality. These systems can detect deviations from desired clearance settings, allowing for immediate corrections and minimizing downtime. Implementing such systems is crucial for maintaining high standards in stamping operations.

Future Trends in Stamping Die Clearance

The future of stamping die clearance lies in increased automation and integration with advanced technologies. As industries move towards smarter manufacturing processes, the role of artificial intelligence and machine learning in optimizing die clearance will become more prominent. These technologies will enable more precise calculations and adjustments, enhancing both quality and efficiency.

Artificial Intelligence and Machine Learning

AI and machine learning can analyze vast amounts of data to identify patterns and optimize die clearance settings. These technologies will increasingly be used to automate the calculation process, reducing human error and improving consistency across manufacturing operations.

Integration with IoT

The Internet of Things (IoT) allows for seamless integration of machines, sensors, and software, facilitating real-time data collection and analysis. This connectivity will further enhance the accuracy and efficiency of stamping operations, making them more responsive to changing conditions and demands.

Conclusion

Understanding and implementing accurate stamping die clearance calculation is crucial for achieving high-quality results in metal stamping. By considering material properties, leveraging advanced technologies, and embracing continuous learning, manufacturers can ensure efficiency, reduce waste, and maintain competitive advantages in their operations. For more insights into the stamping process, manufacturers can explore various resources available online.

FAQs

What is the ideal die clearance for aluminum?

The ideal die clearance for aluminum typically ranges between 5% to 8% of the material thickness. This range ensures a clean cut while minimizing tool wear and extending die life.

How does material hardness affect die clearance?

Material hardness significantly affects die clearance. Harder materials require greater clearance to prevent excessive tool wear and ensure clean cuts, while softer materials can be stamped with smaller clearances.

Can technology help in optimizing die clearance?

Yes, technology plays a critical role in optimizing die clearance. Tools such as CAD software and real-time monitoring systems allow for precise calculations and adjustments, enhancing both efficiency and product quality.

This article contains affiliate links. We may earn a commission at no extra cost to you.