In the world of industrial manufacturing, understanding stamping die breakage causes and fixes is crucial for maintaining efficiency and minimizing downtime. Stamping dies are essential components in the metal stamping process, a method widely used in producing parts for various industries, including automotive, aerospace, and electronics. When these dies break, it can lead to significant delays and increased costs. Therefore, identifying the causes of stamping die breakage and implementing effective fixes is vital for manufacturers.

What is Stamping Die Breakage?

Stamping die breakage refers to the failure of the die used in the metal stamping process. This can occur due to various reasons, ranging from material issues to operational errors. Understanding the root causes of this breakage is essential for implementing the right solutions and preventing future occurrences.

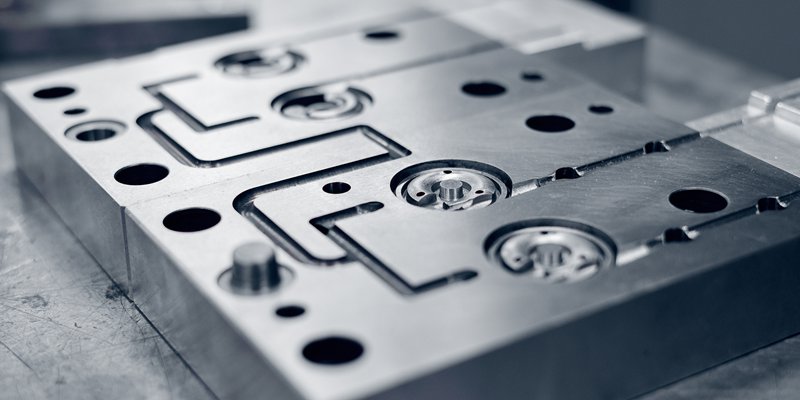

Understanding the Metal Stamping Process

Before diving into the causes and fixes, it’s essential to understand the metal stamping process. In this process, a flat sheet of metal is placed into a stamping press where a die forms the metal into a desired shape. This method is widely used for mass-producing parts due to its efficiency and precision. For more detailed information, you can refer to this Metal Stamping 101 guide.

Common Causes of Stamping Die Breakage

Material Issues

One of the primary causes of die breakage is the use of poor-quality materials. The metal used in the die must be strong enough to withstand the pressures of the stamping process. Using substandard materials can lead to premature wear and breakage.

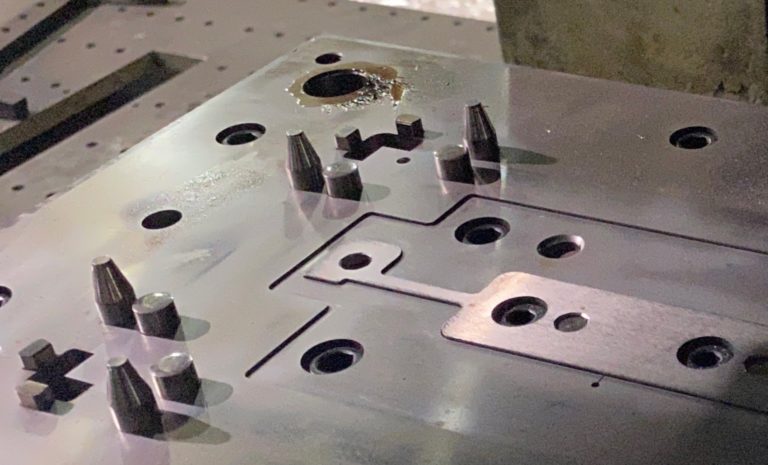

Improper Maintenance

Regular maintenance is crucial for ensuring the longevity of stamping dies. Neglecting maintenance can lead to wear and tear, eventually causing the die to break. Manufacturers should establish a routine maintenance schedule to inspect and service their dies.

Operational Errors

Human error during the stamping process can also contribute to die breakage. Incorrect setup, misalignment, or applying too much pressure can all lead to damage. Proper training and adherence to best practices can help minimize these errors.

Design Flaws

Poorly designed dies are more prone to breakage. Ensuring that the die design is optimized for the intended application is crucial. Working with experienced die designers can help prevent design-related issues.

Effective Fixes for Stamping Die Breakage

Material Selection

Choosing the right materials for both the die and the stamped parts is essential. High-quality, durable materials will help reduce the risk of breakage. Collaborating with material specialists can aid in selecting the best materials for specific applications.

Regular Maintenance

Implementing a regular maintenance schedule can significantly extend the life of stamping dies. This includes routine inspections, cleaning, and lubrication. By staying proactive, manufacturers can address potential issues before they lead to breakage.

Operator Training

Training operators on the best practices of the stamping process is vital. Well-trained operators are less likely to make mistakes that could lead to die breakage. Regular refresher courses and updates on new techniques can enhance operator skills.

Design Optimization

Working with skilled designers to create optimized die designs can prevent breakage. Using advanced software for simulations and stress testing can ensure that the die can handle the required pressures without failing.

Advanced Technologies in Stamping

Incorporating advanced technologies, such as AI and machine learning, can further prevent die breakage. These technologies can predict potential failures and suggest solutions before they occur, thus enhancing overall production efficiency.

Conclusion

Understanding the stamping die breakage causes and fixes is crucial for industrial manufacturers looking to improve efficiency and reduce downtime. By addressing the common causes of die breakage and implementing the right fixes, manufacturers can enhance their production processes. For further insights into improving stamping productivity, visit stamping productivity improvement.

FAQs

What are the signs of a failing stamping die?

Signs of a failing stamping die include unusual noise during operation, visible cracks or wear, and inconsistent stamping results.

How often should stamping dies be maintained?

Stamping dies should be inspected and maintained regularly, with the frequency depending on the production volume and material used. A general rule is every few months.

Can technology help prevent die breakage?

Yes, advanced technologies like AI and machine learning can predict potential failures and suggest preventative measures, thereby reducing the risk of die breakage.

This article contains affiliate links. We may earn a commission at no extra cost to you.