In the world of industrial manufacturing, precision is key. One of the most critical aspects of achieving this precision lies in the use of stamping die alignment tools. These tools are indispensable for ensuring the accuracy and efficiency of the stamping process, which is vital for producing high-quality metal parts.

Understanding Stamping Die Alignment Tools

Stamping die alignment tools are designed to ensure that the components of a die are perfectly aligned. This alignment is crucial for the production of consistent and precise metal parts. Without proper alignment, the quality of the stamped parts can be compromised, leading to increased waste and higher production costs.

Why Alignment is Crucial

Alignment is crucial because it directly impacts the quality of the final product. Misaligned dies can lead to defects such as burrs, incomplete cuts, or even damage to the stamping machine. By using stamping die alignment tools, manufacturers can avoid these issues and ensure that each part meets the required specifications.

Types of Alignment Tools

There are several types of alignment tools available, each designed for specific purposes. These include mechanical, optical, and laser alignment tools. Each type has its own advantages and is chosen based on the specific needs of the manufacturing process.

Mechanical Alignment Tools

Mechanical alignment tools are among the most commonly used in the industry. They are typically used for aligning heavy or large dies. These tools rely on physical measurements and adjustments to achieve precise alignment.

Benefits of Mechanical Tools

Mechanical tools are known for their durability and reliability. They are easy to operate and do not require extensive training, making them a popular choice for many manufacturers.

Optical Alignment Tools

Optical alignment tools use visual indicators to ensure precise alignment. These tools are often used for smaller dies or when high precision is required.

Advantages of Optical Tools

Optical tools provide a high level of accuracy and are ideal for applications where visual inspection is critical. They are also less intrusive than mechanical tools, which can be beneficial in certain manufacturing environments.

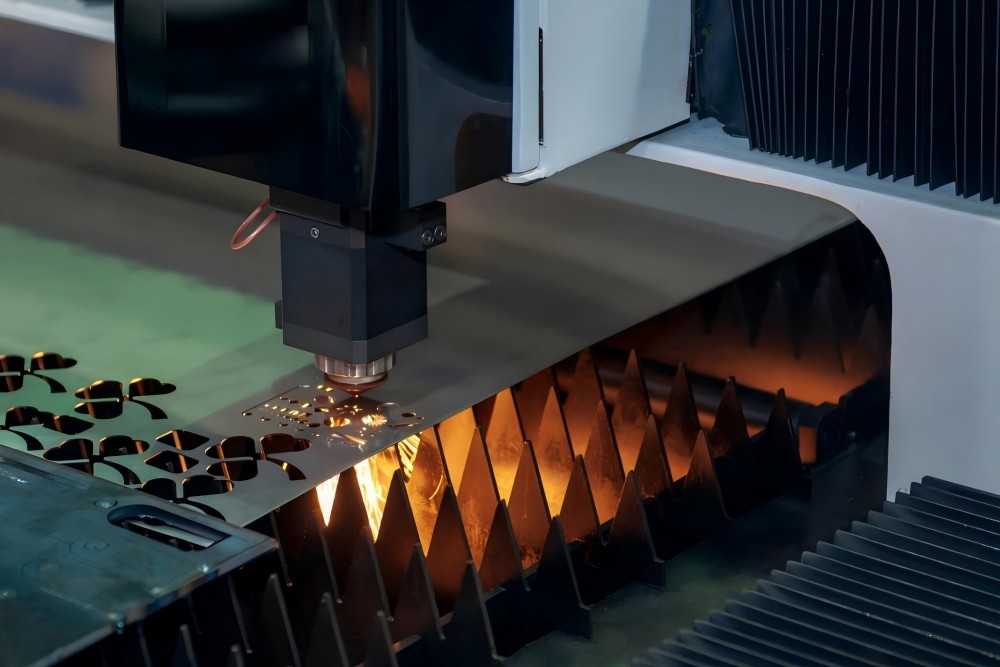

Laser Alignment Tools

Laser alignment tools represent the latest in alignment technology. These tools use laser beams to achieve precise alignment, offering unparalleled accuracy and ease of use.

Benefits of Laser Tools

Laser tools are incredibly precise and can significantly reduce setup time. They are also versatile, as they can be used in a wide range of applications, from small dies to large-scale industrial operations.

Improving Stamping Press Productivity

Proper alignment is just one aspect of improving productivity in stamping operations. Manufacturers can also benefit from exploring other areas such as stamping press productivity improvements.

Quality Control in Stamping

Maintaining high-quality standards is essential in the stamping industry. For more insights on ensuring quality, visit our detailed guide on quality control in stamping production.

Choosing the Right Tools

Choosing the right alignment tools depends on several factors, including the size of the die, the required precision, and the specific manufacturing environment. Manufacturers should consider these factors carefully to select the most suitable tools.

Considerations for Selection

When selecting alignment tools, it is important to consider not only the immediate needs but also future requirements. Investing in versatile tools that can adapt to different applications can provide long-term benefits.

Training and Maintenance

Proper training and maintenance are essential for maximizing the effectiveness of alignment tools. Regular maintenance ensures that the tools remain in optimal condition, while training ensures that operators can use them correctly.

Ensuring Proper Use

Providing comprehensive training programs for operators can significantly improve the effectiveness of alignment tools. This training should cover the correct use of the tools, as well as troubleshooting and maintenance procedures.

Impact on Production Costs

Using the right alignment tools can help reduce production costs by minimizing waste and improving efficiency. By ensuring that each part is produced to the required specifications, manufacturers can reduce the need for rework and lower overall production costs.

Cost Savings

The cost savings achieved through proper alignment can be substantial. By reducing defects and improving efficiency, manufacturers can increase their profitability and gain a competitive edge in the market.

Future of Stamping Die Alignment Tools

The future of stamping die alignment tools looks promising, with technological advancements continuing to improve their accuracy and ease of use. As the industry evolves, we can expect to see even more innovative solutions that enhance precision and efficiency.

Innovations to Watch

Innovations in alignment technology, such as the integration of artificial intelligence and automation, are likely to shape the future of the industry. These advancements will provide manufacturers with even more powerful tools to achieve precise alignment.

FAQs

What are stamping die alignment tools?

Stamping die alignment tools are devices used to ensure that the components of a die are perfectly aligned, which is crucial for producing high-quality metal parts.

Why is alignment important in stamping?

Alignment is important because it directly impacts the quality of the final product. Proper alignment ensures that each part meets the required specifications, reducing waste and production costs.

What are the types of alignment tools?

The main types of alignment tools are mechanical, optical, and laser tools. Each type has its own advantages and is chosen based on the specific needs of the manufacturing process.

Conclusion

In conclusion, stamping die alignment tools are essential for achieving precision and efficiency in industrial manufacturing. By choosing the right tools and ensuring proper training and maintenance, manufacturers can significantly improve the quality of their products and reduce production costs. As technology continues to advance, we can expect even more innovative solutions to emerge, further enhancing the capabilities of these essential tools.

This article contains affiliate links. We may earn a commission at no extra cost to you.